Preparation method of composite electro-spun tissue engineering scaffold material, engineering scaffold material and application thereof

A tissue engineering scaffold and electrospinning technology, which is applied in textiles and papermaking, rayon manufacturing, and conjugated synthetic polymer artificial filaments, etc., can solve degradation product cells, tissue damage, structure vulnerable to external force damage, and related complications and other issues, to achieve good mechanical properties and biocompatibility, improve bioavailability, and proper degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

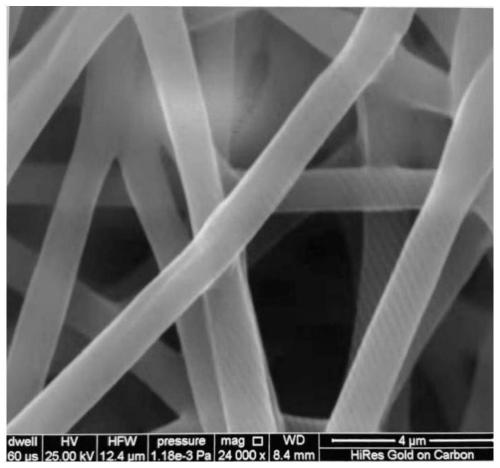

Image

Examples

Embodiment 1

[0028] A preparation method for a composite electrospun tissue engineering scaffold material, comprising the steps of:

[0029] S1. Preparation of poly(3-hydroxybutyrate-4-hydroxybutyrate) / L-polylactic acid electrospun fibers: Weigh 40 mg of medical-grade P34HB powder (purity greater than 99.5%) and 40 mg of medical-grade L-lactic acid The powder was dissolved in a composite solvent of 1000 mL of dichloromethane and dimethylformamide (DMF) (the volume ratio of dichloromethane and dimethylformamide was 3:7), stirred and dissolved by a magnetic stirrer for 2 hours, and the temperature was 60 ℃, stir evenly, and make P34HB / PLLA solution.

[0030] S2. Preparation of polyhydroxyalkanoate / L-polylactic acid composite electrospun fiber mixed solution loaded with epirubicin: Weigh 5 mg of epirubicin and add poly(3-hydroxybutyrate-4- Hydroxybutyrate) / L-polylactic acid electrospun fiber solution, continue magnetic stirring until the epirubicin is completely dissolved.

[0031] S3. Add ...

Embodiment 2

[0033]A preparation method for a composite electrospun tissue engineering scaffold material, comprising the steps of:

[0034] S1. Preparation of poly(3-hydroxybutyrate-4-hydroxybutyrate) / poly-L-lactic acid electrospun fibers: Weigh 40 mg of medical-grade P34HB powder (purity greater than 99.5%) and 32 mg of medical-grade poly-L-lactic acid The powder was dissolved in a composite solvent of 1000 mL of dichloromethane and dimethylformamide (DMF) (the volume ratio of dichloromethane and dimethylformamide was 6:4), stirred and dissolved by a magnetic stirrer for 2 hours, and the temperature was 60 ℃, stir evenly, and make P34HB / PLLA solution.

[0035] S2. Preparation of polyhydroxyalkanoate / L-polylactic acid composite electrospun fiber mixed solution loaded with epirubicin: Weigh 4 mg of epirubicin and add poly(3-hydroxybutyrate-4- Hydroxybutyrate) / L-polylactic acid electrospun fiber solution, continue magnetic stirring until the epirubicin is completely dissolved.

[0036] S3....

Embodiment 3

[0038] A preparation method for a composite electrospun tissue engineering scaffold material, comprising the steps of:

[0039] S1. Preparation of poly(3-hydroxybutyrate-4-hydroxybutyrate) / L-lactic acid electrospun fibers: Weigh 40 mg of medical-grade P34HB powder (purity greater than 99.5%) and 48 mg of medical-grade L-lactic acid The powder was dissolved in a composite solvent of 1000 mL of dichloromethane and dimethylformamide (DMF) (the volume ratio of dichloromethane and dimethylformamide was 2:8), stirred and dissolved by a magnetic stirrer for 2 hours, and the temperature was 60 ℃, stir evenly, and make P34HB / PLLA solution.

[0040] S2. Preparation of polyhydroxyalkanoate / L-polylactic acid composite electrospun fiber mixed solution loaded with epirubicin: Weigh 6 mg of epirubicin and add poly(3-hydroxybutyrate-4- Hydroxybutyrate) / L-polylactic acid electrospun fiber solution, continue magnetic stirring until the epirubicin is completely dissolved.

[0041] S3. Add the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com