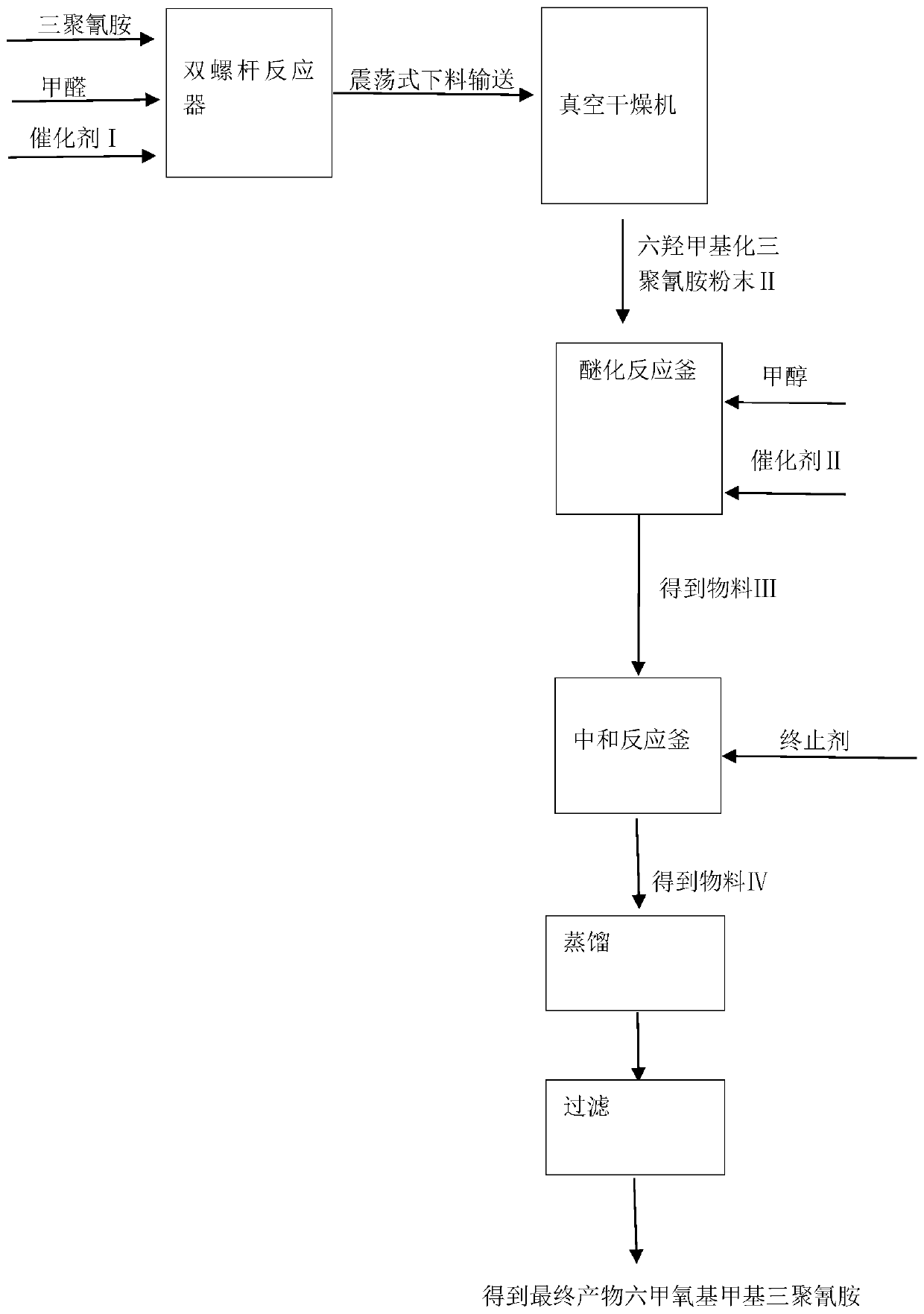

Preparation method for continuously and stably producing highly etherified hexamethoxymethyl melamine

A technology of hexamethoxymethyl melamine and hexamethylolated melamine, which is applied in the field of preparation of hexamethoxymethyl melamine, can solve the problem of unstable quality of hexamethoxymethyl melamine, high content of free formaldehyde and long reaction time and other problems, to achieve the effect of long reaction residence time, low free formaldehyde content and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Polyformaldehyde and hydrolysis polymerize into a formaldehyde aqueous solution with a mass concentration of 30% and heat it up to 70°C for later use. Melamine powder and water are prepared into melamine slurry at a weight ratio of 1:1 and keep warm at 25°C for later use. Prepare good quality The sodium hydroxide solution with a concentration of 10% is pumped into the catalyst I tank for standby, and the mold temperature controller of the twin-screw extruder is preheated to 60°C. Methanol is pumped into the head tank to raise the temperature to 60°C for standby, and nitric acid is pumped into the catalyst II tank for standby. Continuously add melamine slurry, 30% formaldehyde solution and 10% sodium hydroxide into twin-screw extruder to carry out methylolation reaction to obtain material I, wherein the melamine slurry flow rate is 25.7Kg / h, 30% The flow rate of formaldehyde solution is 70Kg / h, the flow rate of 10% sodium hydroxide solution is 0.42Kg / h, the length-to...

Embodiment 2 to Embodiment 4

[0043] The experiment of embodiment 2 to embodiment 4 is carried out according to each step of embodiment 1, and only difference is that reaction parameter is different, specifically see table 2, the product quality detection data of the hexamethoxymethyl melamine of the continuous quality stability that prepares is as follows Table 5 shows.

[0044] The reaction parameter of table 2 embodiment 1 to embodiment 4

[0045]

[0046]

Embodiment 5 to Embodiment 8

[0048] The experiment of embodiment 5 to embodiment 8 is carried out according to each step of embodiment 1, and only difference is that reaction parameter is different, specifically see table 3, the product quality inspection data of the hexamethoxymethyl melamine of the continuous quality stability that prepares is as follows Table 5 shows.

[0049] The reaction parameter of table 3 embodiment 5 to embodiment 8

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com