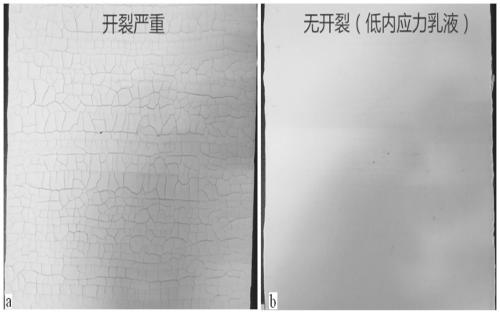

Low-internal-stress acrylic emulsion and preparation method thereof

An acrylic emulsion and internal stress technology, which is applied in the direction of coating, etc., can solve the problems of manpower consumption, material resources, financial resources, and solid waste pollution of the environment, and achieve the effect of reducing TG, reducing internal stress, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In addition, the present invention also provides the preparation method of described low internal stress acrylic emulsion, comprising steps:

[0045] (1) Pre-emulsion A: At normal temperature and pressure, add 10%-20% of the mass of the anionic emulsifier in the emulsifier and 25% of the mass of the non-ionic emulsifier, and 10-20 parts of distilled water in the emulsification tank A , fully stirred to dissolve, and sequentially added 10-20 parts of methyl methacrylate, 0.03-0.1 part of cross-linking monomer, 0.05-0.1 part of initiator, fully stirred for 20-30 minutes, prepared pre-emulsion A, and set aside;

[0046] (2) Pre-emulsion B: under normal temperature and pressure, add 20%-30% of the mass of anionic emulsifier and 25% of the mass of non-ionic emulsifier, and 40-60 parts of distilled water into pre-emulsification cylinder B, fully stir and dissolve, Then add the remaining amount of methyl methacrylate, the formula amount of alkyl acrylate, the formula amount of...

Embodiment 1

[0054] A kind of low internal stress acrylic emulsion, by mass parts, is made of following raw material: 90 parts of distilled water, 40 parts of methyl methacrylate, 40 parts of butyl acrylate, 1 part of acrylic acid, emulsifier (2 parts of anionic emulsifier SR-10, 1 part of nonionic emulsifier LCN118), 0.1 part of vinyltrimethoxysilane, 0.1 part of pretreated glycidyl methacrylate, 0.5 part of potassium persulfate, 0.1 part of tert-butyl hydroperoxide , 0.1 parts of vitamin C, and 5 parts of NaOH with a mass fraction of 10%.

[0055] The preparation method of described low internal stress acrylic acid emulsion, comprises the steps:

[0056] (1) Pre-emulsion A: under normal temperature and pressure, add 10% of the quality of the anionic emulsifier SR-10 and 25% of the quality of the nonionic emulsifier LCN118 in the emulsifier, 10 parts of distilled water in the emulsification tank A, Stir fully to dissolve, and add 10 parts of methyl methacrylate, 0.05 parts of vinyltrimet...

Embodiment 2

[0067] A kind of low internal stress acrylic emulsion, by mass parts, is made of the following raw materials: 90 parts of distilled water, 30 parts of methyl methacrylate, 50 parts of butyl acrylate, 1 part of acrylic acid, emulsifier (2 parts of anionic emulsifier RS -610, 1 part of nonionic emulsifier LCN118), 0.1 part of vinyl triethoxysilane, 0.1 part of glycidyl methacrylate after pretreatment, 0.5 part of potassium persulfate, 0.1 part of tert-butyl hydroperoxide, 0.1 parts of vitamin C, 10 parts of NaOH with a mass fraction of 10%.

[0068] In addition, the present invention also provides the preparation method of described low internal stress acrylic emulsion, comprising steps:

[0069] (1) Pre-emulsion A: under normal temperature and pressure, add 15% of the quality of the anionic emulsifier RS-610 in the emulsifier and 25% of the quality of the nonionic emulsifier LCN118, 10 parts of distilled water in the emulsification tank A, Stir fully to dissolve, and add 10 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com