Self-repairing anticorrosive coating and preparation method thereof

An anti-corrosion coating and self-repairing technology, which is applied in the field of anti-corrosion coatings, can solve problems such as insufficient anti-corrosion performance and mechanical properties, and achieve the effects of improved anti-corrosion performance, good flexibility, and reduced penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

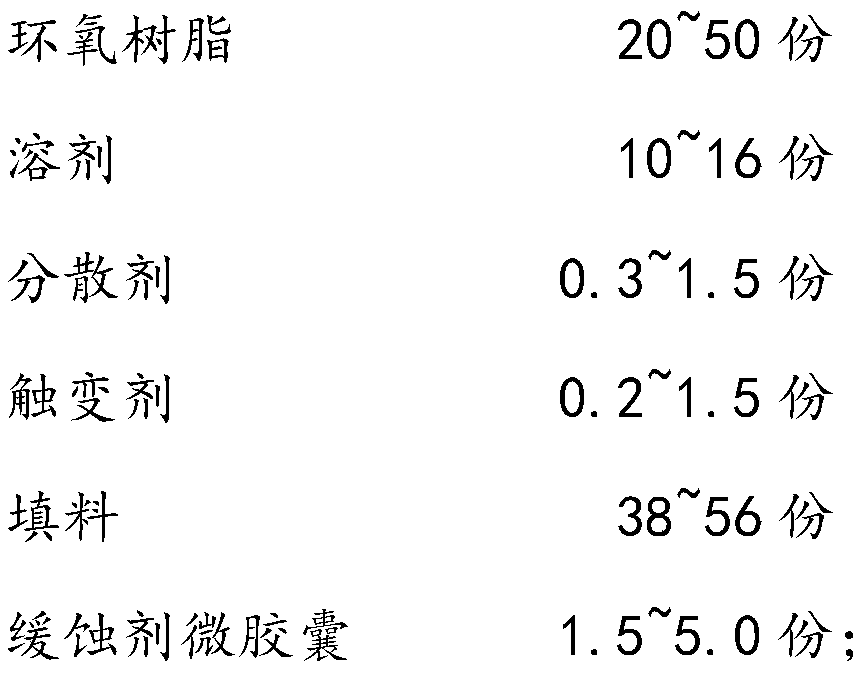

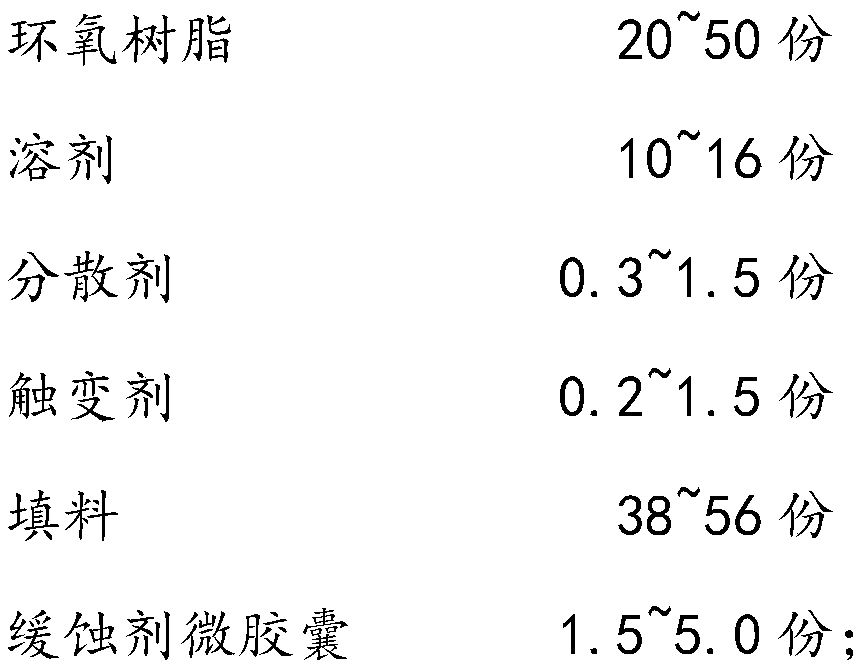

Method used

Image

Examples

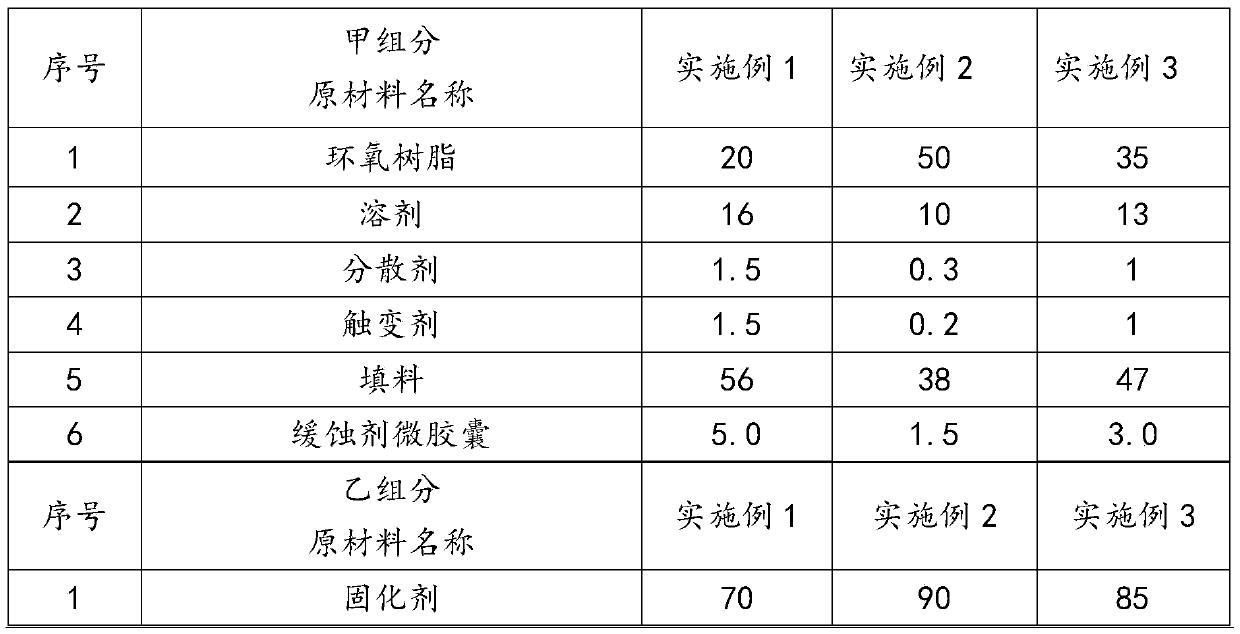

Embodiment 1

[0041] In the first component of embodiment 1: the epoxy resin is 6101 epoxy resin (the trade mark is E44), and the solvent is xylene and n-butanol; the dispersant is EFKA-4310; the thixotropic agent is 140# organic bentonite and Ultra polyamide wax The filler is talcum powder, precipitated barium sulfate, barite powder, mica powder, sericite powder, aluminum tripolyphosphate, feldspar powder. ; In the second component: the curing agent is BS805 curing agent; the solvent is xylene and n-butanol, wherein the weight ratio of the first component and the second component is 6:1;

Embodiment 2

[0042] In the first component of embodiment 2: the epoxy resin is 618 epoxy resin (the trade mark is E51), and the solvent is xylene and cyclohexanone; the dispersant is BYK-220s; the thixotropic agent is 140# bentonite; the filler is talcum powder , precipitated barium sulfate, barite powder, mica powder, sericite powder, mica iron oxide, feldspar powder; in component B: curing agent is MD2015 cashew nut shell oil phenalkamine curing agent; solvent is xylene, component A and The weight ratio of component B is 3:1;

Embodiment 3

[0043] In the first component of embodiment 3: the epoxy resin is a blend of 6101 epoxy resin and 618 epoxy resin, the solvent is xylene and n-butanol; the dispersant is BYK-110; the thixotropic agent is 140# organic bentonite and Ultra Polyamide wax; fillers are talcum powder, precipitated barium sulfate, barite powder, ferrophosphorus powder, mica iron oxide, feldspar powder; in component B: curing agent is BS8328 polyamide curing agent and KDX2015 cashew nut shell oil phenalkamine curing The solvent is xylene; the weight ratio of component A and component B is 4:1.

[0044] In each embodiment, the corrosion inhibitor microcapsules are prepared by the following preparation method:

[0045]Step 1: Take 0.2g sodium lauryl sulfate, 15g barium petroleum sulfonate, and 0.8g n-hexadecane, disperse them in 80mL water, and ultrasonicate for 5-10min to form an oil-in-water emulsion;

[0046] Step 2: Add 5g acrylic acid solution to the prepared oil-in-water emulsion in step 1, 0.02g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com