Organic-inorganic hybrid shell bifunctional phase change capsule and preparation method thereof

A phase-change capsule and dual-function technology, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems of single, easy-to-shrink functionality of the shell, poor thermal conductivity, etc., to increase heat transfer efficiency , taking into account product performance and environmental friendliness, the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

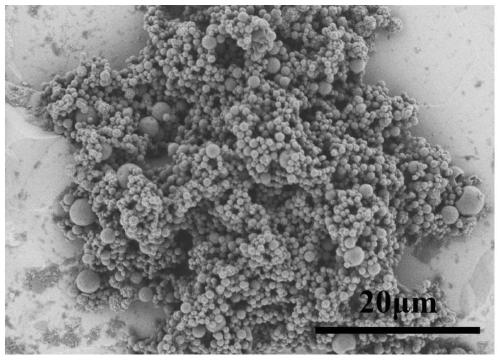

[0049] In a 500mL single-necked flask, take 200mL of deionized water and weigh 2g of nano-TiO 2 (particle size 25 nanometers) and 2mL KH-570, and disperse them, add concentrated HCl (reagent grade) to adjust the pH to 4-5, stir the above mixture with a constant temperature magnetic stirrer for 30min, ultrasonic at 60% amplitude for 20min, insert The circulating water was condensed, and finally the flask was transferred to an oil bath at 80°C to react for 5 hours. Subsequently, the mixture was centrifuged in a centrifuge at 5000rpm for 2h, the supernatant was poured out, washed three times with absolute ethanol, and finally the solid product was dried in a vacuum oven at 65°C for 12h to obtain KH-570 modified TiO 2 .

[0050] 2g modified nano-TiO 2 Mix with 150g of deionized water, and shear at a high speed of 8000rpm for 20min with a high-speed disperser. Then it was added to an ultrasonic cell disruptor and ultrasonicated at 60% amplitude for 30 minutes to obtain a water p...

Embodiment 2

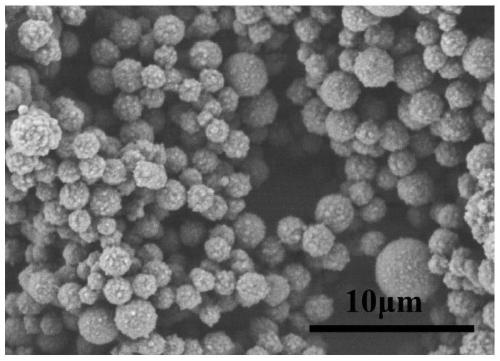

[0059] In a 500mL single-necked flask, measure 150mL of deionized water and weigh 1.5g of nano-TiO 2 and 1.5mL KH-570 and dispersed in it, added concentrated HCl to adjust the pH to 4-5, stirred the above mixture with a constant temperature magnetic stirrer for 30min, ultrasonicated at 60% amplitude for 30min, connected to condensing circulating water, and finally transferred the flask to React in an oil bath at 80°C for 6h. Subsequently, the mixture was centrifuged in a centrifuge at 5000rpm for 2h, the supernatant was poured out, washed three times with absolute ethanol, and finally the solid product was dried in a vacuum oven at 65°C for 12h to obtain KH-570 modified TiO 2 .

[0060] 1.5g modified nano-TiO 2 Mix with 200g of deionized water, and shear at a high speed of 6000rpm for 20min with a high-speed disperser. Then it was added to an ultrasonic cell disruptor, and the amplitude of 60% was ultrasonicated for 30 minutes to obtain an aqueous phase; 4 g of DVB, 5 g of ...

Embodiment 3

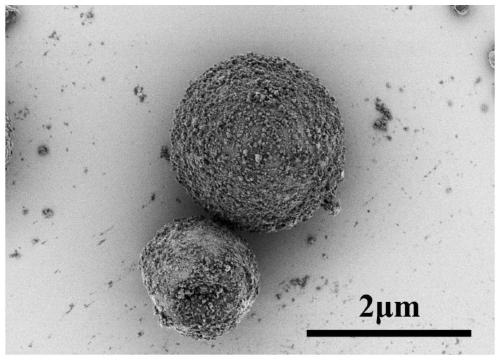

[0063] In a 250mL single-necked flask, measure 100mL of deionized water and weigh 0.5g of nano-TiO 2 and 0.5mL KH-570 and dispersed in it, added concentrated HCl to adjust the pH to 4-5, stirred the above mixture with a constant temperature magnetic stirrer for 30min, ultrasonicated at 60% amplitude for 30min, connected to condensing circulating water, and finally transferred the flask to React in an oil bath at 80°C for 8h. Subsequently, the mixture was centrifuged in a centrifuge at 5000rpm for 2h, the supernatant was poured out, washed three times with absolute ethanol, and finally the solid product was dried in a vacuum oven at 65°C for 12h to obtain KH-570 modified TiO 2 .

[0064] 0.5g modified nano-TiO 2 Mix with 250g of deionized water, and shear at a high speed of 4000rpm for 20min with a high-speed disperser. Then it was added to an ultrasonic cell breaker, and the amplitude of 60% was sonicated for 30 minutes to obtain an aqueous phase; 4.5 g DVB, 5 g paraffin an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com