Preparation method of two-dimensional titanium carbide/two-dimensional graphite phase carbon nitride nanosheet heterojunction and application of heterojunction in photocatalytic reduction of CO2

A technology of graphite phase carbon nitride and two-dimensional titanium carbide, which is applied in the direction of carbon monoxide, hydrocarbon production from carbon oxides, physical/chemical process catalysts, etc., can solve time-consuming and cumbersome, low yield of ultra-thin titanium carbide nanosheets, Waste of raw materials and other problems, to achieve the effect of short time consumption, alleviating energy crisis, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

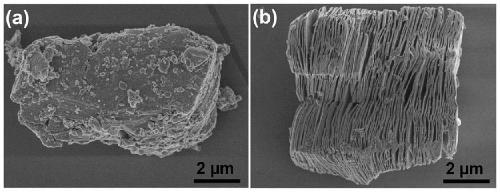

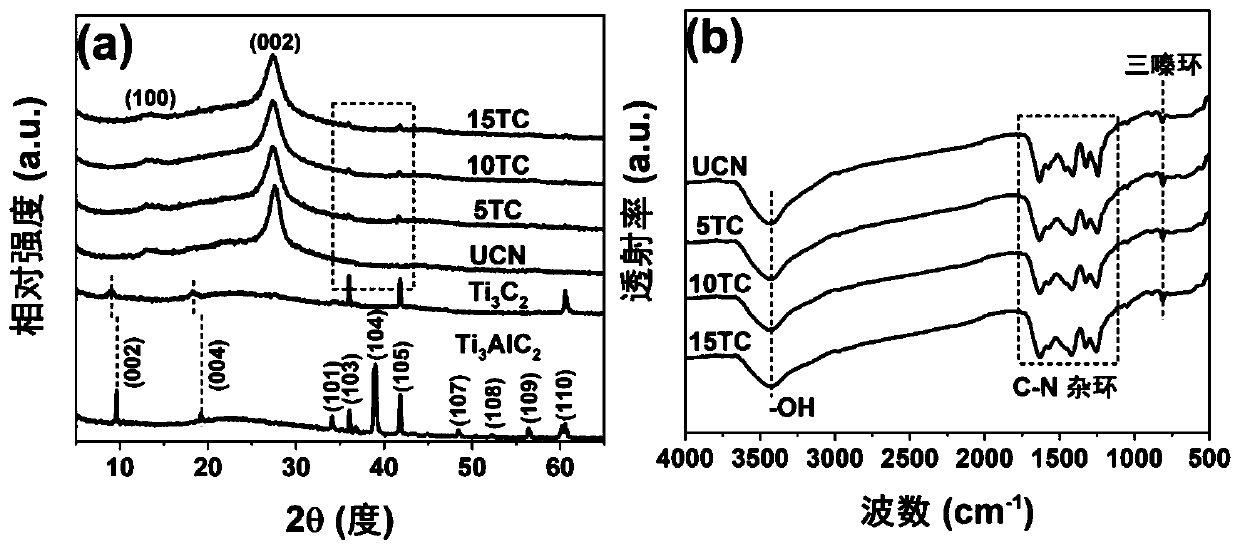

[0030] A highly visible photocatalytic reduction of CO 2 Preparation method of active ultrathin two-dimensional titanium carbide / two-dimensional graphite phase carbon nitride nanosheet heterojunction:

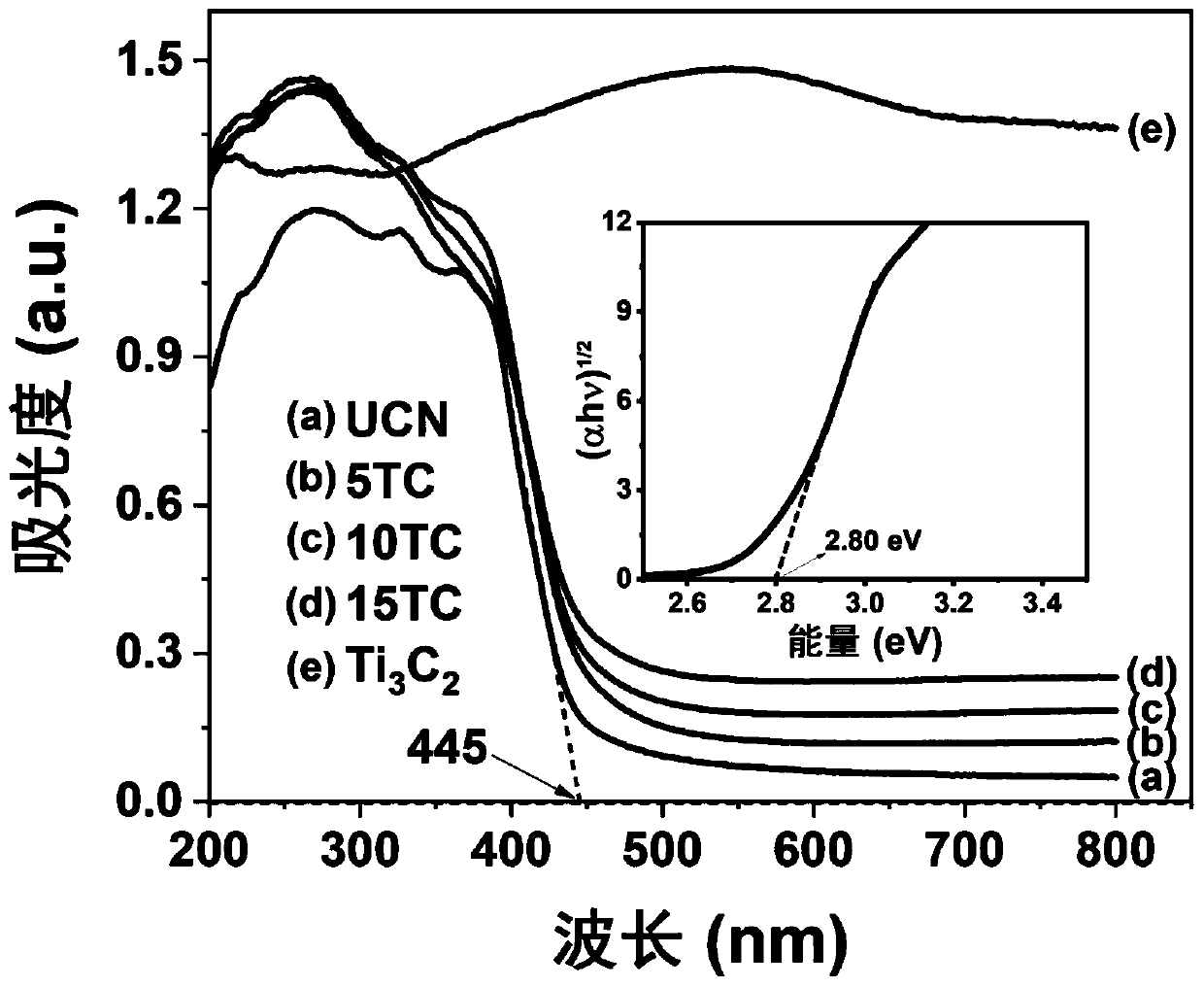

[0031] Take 10mg of titanium carbide powder and disperse it into 20mL urea solution (500g L -1), ultrasonicated for 2 h in an ice-water bath to obtain a homogeneous mixture. Dry the mixed solution at 60°C to obtain a titanium carbide-urea precursor. TiC-urea precursor in N 2 Atmosphere, at 10℃·min -1 The heating rate was raised to 550°C and then heat-preserved and calcined for 2 hours to obtain an ultra-thin two-dimensional titanium carbide / two-dimensional graphite phase carbon nitride nanosheet heterojunction catalyst (the catalyst is marked as 10TC), and the yield should be 100%, because there is no separation loss in the process.

[0032] The specific surface area of the composite catalyst 10TC sample is 45.9m 2 g -1 , whose photocatalytic reduction of CO 2 The con...

Embodiment 2

[0034] A preparation method of ultra-thin two-dimensional titanium carbide / two-dimensional graphite phase carbon nitride nanosheet heterojunction with high activity in visible light catalytic reduction of carbon dioxide:

[0035] In order to investigate the effect of the addition of TiC on the photocatalytic reduction of CO over ultrathin 2D TiC / 2D graphite phase carbon nitride nanosheet heterojunction catalysts 2 In terms of performance, except that the amount of titanium carbide added was changed to 5 mg, the preparation method of the catalyst was exactly the same as in Example 1, and the obtained sample was marked as 5TC.

[0036] The specific surface area of the composite catalyst 5TC sample is 37.6m 2 g -1 , whose photocatalytic reduction of CO 2 The conversion rate is 1.75 μmol h -1 g -1 (CO and CH 4 The formation rates of are 1.72 and 0.030 μmol·h, respectively -1 g -1 ).

Embodiment 3

[0038] A preparation method of ultra-thin two-dimensional titanium carbide / two-dimensional graphite phase carbon nitride nanosheet heterojunction with high activity in visible light catalytic reduction of carbon dioxide:

[0039] In order to investigate the effect of the addition of TiC on the photocatalytic reduction of CO over ultrathin 2D TiC / 2D graphite phase carbon nitride nanosheet heterojunction catalysts 2 The impact on performance, except that the addition of titanium carbide was changed to 15 mg, the preparation method of the catalyst was exactly the same as in Example 1, and the obtained sample was marked as 15TC.

[0040] The specific surface area of composite catalyst 15TC sample is 41.1m 2 g -1 , whose photocatalytic reduction of CO 2 The conversion rate is 3.98μmol·h -1 g -1 (CO and CH 4 The formation rates of are 3.95 and 0.034 μmol·h, respectively -1 g -1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com