A kind of ultra-light graphene/multi-wall carbon nanotube composite wave absorbing foam and preparation method thereof

A technology of multi-walled carbon nanotubes and graphene, which is applied in the fields of carbon compounds, chemical instruments and methods, ceramic products, etc., can solve the problems of limited aerogel volume, uncontrollable shape, complex aerogel process, etc. , to achieve the effect of short process flow, excellent absorbing performance and controllable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

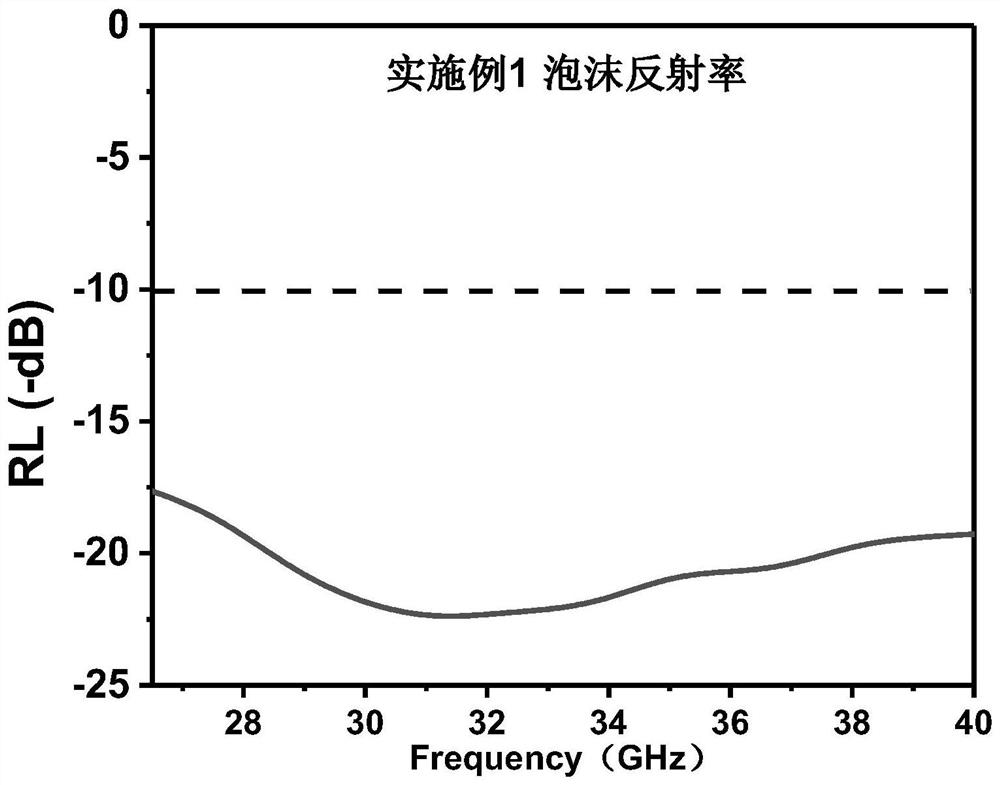

Embodiment 1

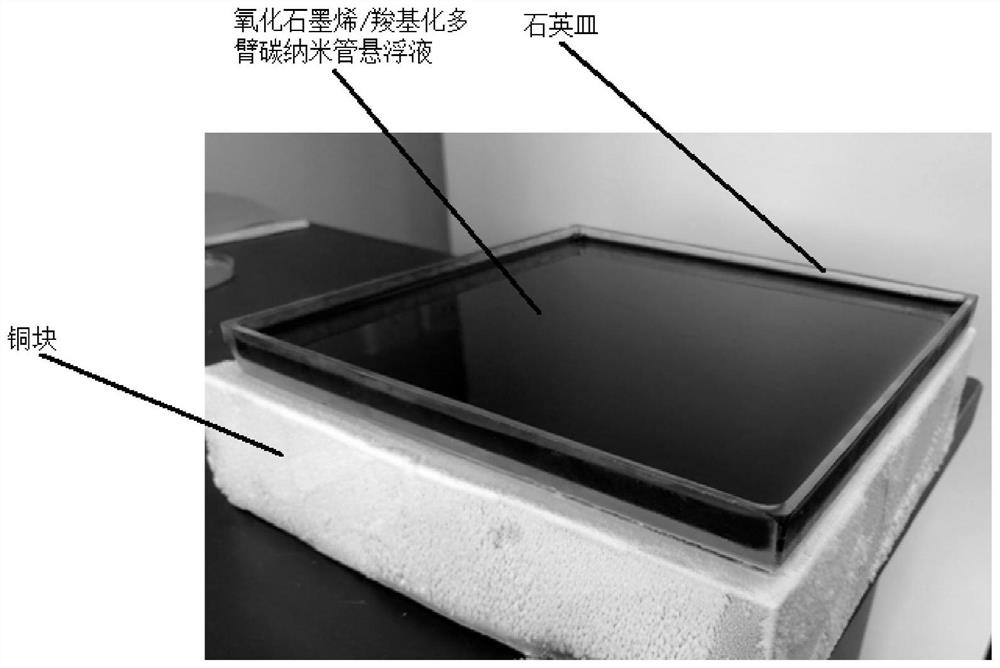

[0046] 1) Take 421mg of graphene oxide, 84.2mg of carboxylated multi-walled carbon nanotubes and 72.2mL of deionized water and mix them. After ultrasonic treatment at 500W for 30min, stir magnetically for 1h. After stirring, add 5.6mL of absolute ethanol.

[0047] 2) Put the suspension obtained in step 1) into an environment with a vacuum degree of 0.04 MPa and let it stand for 10 minutes.

[0048] 3) Put the polished copper block whose length, width and height are 200*200*50mm into a low-temperature refrigerator to freeze until the temperature is -85°C, take out the copper block and put it in an environment with a room temperature of 20°C, and place the inner diameter on it A quartz dish with a size of 190*190*10mm, a wall thickness of 2mm, and rounded corners of φ=1mm is used, and the suspension in step 2) is poured into the quartz dish, and wait for about 6 minutes until the suspension is solidified.

[0049] 4) Put the quartz dish in step 3) together with the solidified su...

Embodiment 2

[0053] 1) Take 421mg of graphene oxide, 84.2mg of carboxylated multi-walled carbon nanotubes and 72.2mL of deionized water and mix them. After ultrasonic treatment at 500W for 30min, stir magnetically for 1h. After stirring, add 2.8mL of absolute ethanol.

[0054] 2) Put the suspension obtained in step 1) into an environment with a vacuum degree of 0.04 MPa and let it stand for 10 minutes.

[0055] 3) Put the polished copper block whose length, width and height are 200*200*50mm into a low-temperature refrigerator to freeze until the temperature is -85°C, take out the copper block and put it in an environment with a room temperature of 20°C, and place the inner diameter on it A quartz dish with a size of 190*190*10mm, a wall thickness of 2mm, and rounded corners of φ=1mm is used, and the suspension in step 2) is poured into the quartz dish, and wait for about 6 minutes until the suspension is solidified.

[0056] 4) Put the quartz dish in step 3) together with the solidified su...

Embodiment 3

[0060] 1) Take 842mg of graphene oxide, 168.4mg of carboxylated multi-walled carbon nanotubes and 144.4mL of deionized water and mix them. After ultrasonic treatment at 500W for 30min, stir magnetically for 1h. After stirring, add 5.6mL of absolute ethanol.

[0061] 2) Put the suspension obtained in step 1) into an environment with a vacuum degree of 0.04 MPa and let it stand for 10 minutes.

[0062] 3) Put the polished copper block whose length, width and height are 200*200*50mm into a low-temperature refrigerator to freeze until the temperature is -85°C, take out the copper block and put it in an environment with a room temperature of 20°C, and place the inner diameter on it A quartz dish with a size of 190*190*10mm, a wall thickness of 2mm, and rounded corners of φ=1mm is used, and the suspension in step 2) is poured into the quartz dish, and wait for about 18 minutes until the suspension is solidified.

[0063] 4) Put the quartz dish in step 3) together with the solidified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com