Preparation method and application of Ag nanosheet SERS substrate packed on aluminum foil

A nanosheet and aluminum foil technology is applied in the field of preparation of Ag nanosheets as SERS substrates, which can solve the problems of poor structural uniformity, inconvenience, and dispersion of Ag nanostructures, and achieve the effects of convenient use and storage, firm structure, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Specifically, the preparation method of the SERS substrate may include the following embodiments:

[0032] Step (1) The aluminum foil is of any size, flattened and polished off the oxide layer on the surface of the aluminum foil with 1000-300 mesh sandpaper; then ultrasonicated with ethanol and water for 3 minutes, rinsed with a large amount of water, and dried with nitrogen gas for later use.

[0033] Step (2) Add NaF containing 30mM and HNO in the glass container 3 15mM mixed solution, the clean Al foil was immersed in the above mixed solution for 1min.

[0034] The mixed solution described in step (3) contains AgNO 3 20-40mM and 3mM sodium citrate, AgNO 3 The reaction time with aluminum foil is 15-60 minutes.

Embodiment 1

[0037] A preparation method for an assembled Ag nanosheet SERS substrate on an aluminum foil, comprising the following steps:

[0038] (1) Use 500-mesh sandpaper to polish and remove the aluminum oxide film on the surface of the aluminum foil, ultrasonically in ethanol and water respectively, rinse with a large amount of water, and blow dry with nitrogen;

[0039] (2) Add 0.8mL of 30mM NaF and 15mM dilute HNO to a glass container 3 Immerse the clean Al foil in the above mixed solution for 1min.

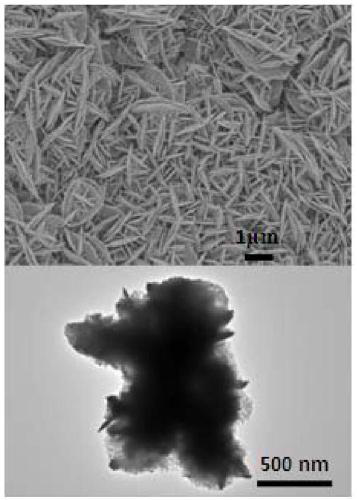

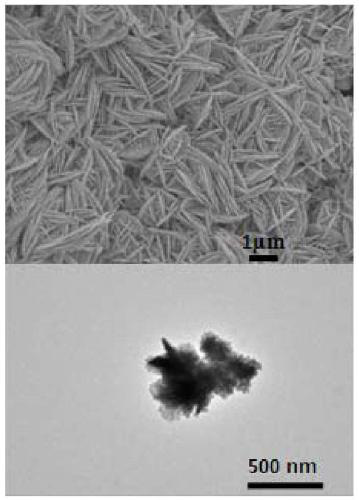

[0040] (3) 1.7ml containing 30mMAgNO 3 and the mixed solution of 3mM sodium citrate are quickly added to the mixed solution described in step (2), so that AgNO 3 React with aluminum foil, the reaction time is 15, 30 and 60min.

[0041] (4) Rinse the aluminum foil covered by the Ag nanosheets prepared in step (3) with a large amount of water, and then immerse them in 4-mercaptopyridine (10 -6 M) in the aqueous solution for 2h, rinse with a large amount of water and blow dry with ni...

Embodiment 2

[0043] A preparation method for an assembled Ag nanosheet SERS substrate on an aluminum foil, comprising the following steps:

[0044] (1) Use 500-mesh sandpaper to polish and remove the aluminum oxide film on the surface of the aluminum foil, ultrasonically in ethanol and water respectively, rinse with a large amount of water, and blow dry with nitrogen;

[0045] (2) Add 0.8mL of 30mM NaF and 15mM dilute HNO to a glass container3 Immerse the clean Al foil in the above mixed solution for 1 min.

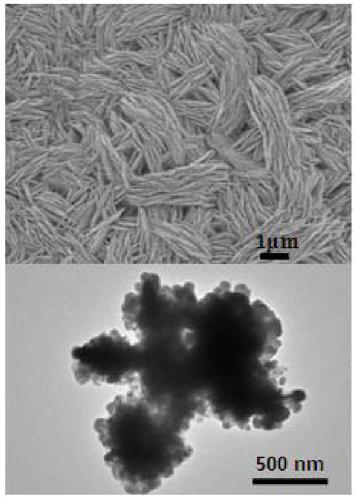

[0046] (3) 1.7ml containing 20mMAgNO 3 and the mixed solution of 3mM sodium citrate are quickly added to the mixed solution described in step (2), so that AgNO 3 React with aluminum foil, the reaction time is 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com