pH-sensitive gel microcapsule and preparation method therefor

A microcapsule and gel technology, applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of protein membrane damage, difficult absorption and utilization of nutrients, loss of fat-soluble nutrients, etc., to achieve good long-term stability and improve embedding rate, the effect of reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Preparation of pH-sensitive lycopene gel microcapsules

[0039] Raw materials: see Table 1.

[0040] The composition list of raw materials used in table 1

[0041]

[0042] *Sample 1 was prepared using ethanol as a solvent with a concentration of 6% (w / v) ethylcellulose-NH 4 OH solution;

[0043] *Sample 2 was prepared using ethanol as a solvent with a concentration of 0.1% (w / v) ethylcellulose-NH 4 OH solution;

[0044] *Sample 3 was prepared using ethanol as a solvent with a concentration of 0.5% (w / v) methylcellulose-NH 4 OH solution.

[0045] Preparation:

[0046] 1. Put the above-mentioned alginate, stabilizer, auxiliary wall material and purified water into the water phase tank, fully stir and mix, and raise the temperature to 50°C under normal pressure, and configure it as water phase material;

[0047] 2. Put emulsified calcium salts, antioxidants, and fat-soluble nutrients into the oil phase tank, stir and mix thoroughly, and heat up to ...

Embodiment 2

[0051] Embodiment 2: Preparation of pH-sensitive fish oil gel microcapsules

[0052] Raw materials: see Table 2.

[0053] The composition list of raw materials used in table 2

[0054]

[0055] *Sample 4 was prepared using acetone as solvent with a concentration of 5% (w / v) methylcellulose-NH 4 OH solution;

[0056] *Sample 5 was prepared using petroleum ether as a solvent with a concentration of 1.5% (w / v) carboxymethylcellulose-NH 4 OH solution;

[0057] *Sample 6 was prepared using propylene dione as a solvent with a concentration of 4% (w / v) hydroxypropyl cellulose-NH 4 OH solution;

[0058] Preparation:

[0059] 1. Put the above-mentioned alginate, stabilizer, auxiliary wall material, and purified water into the water phase tank according to a certain mass percentage, fully stir and mix, and raise the temperature to 54°C under normal pressure, and configure it as a water phase material;

[0060] 2. Put emulsified calcium salts, antioxidants, and fat-soluble nutr...

Embodiment 3

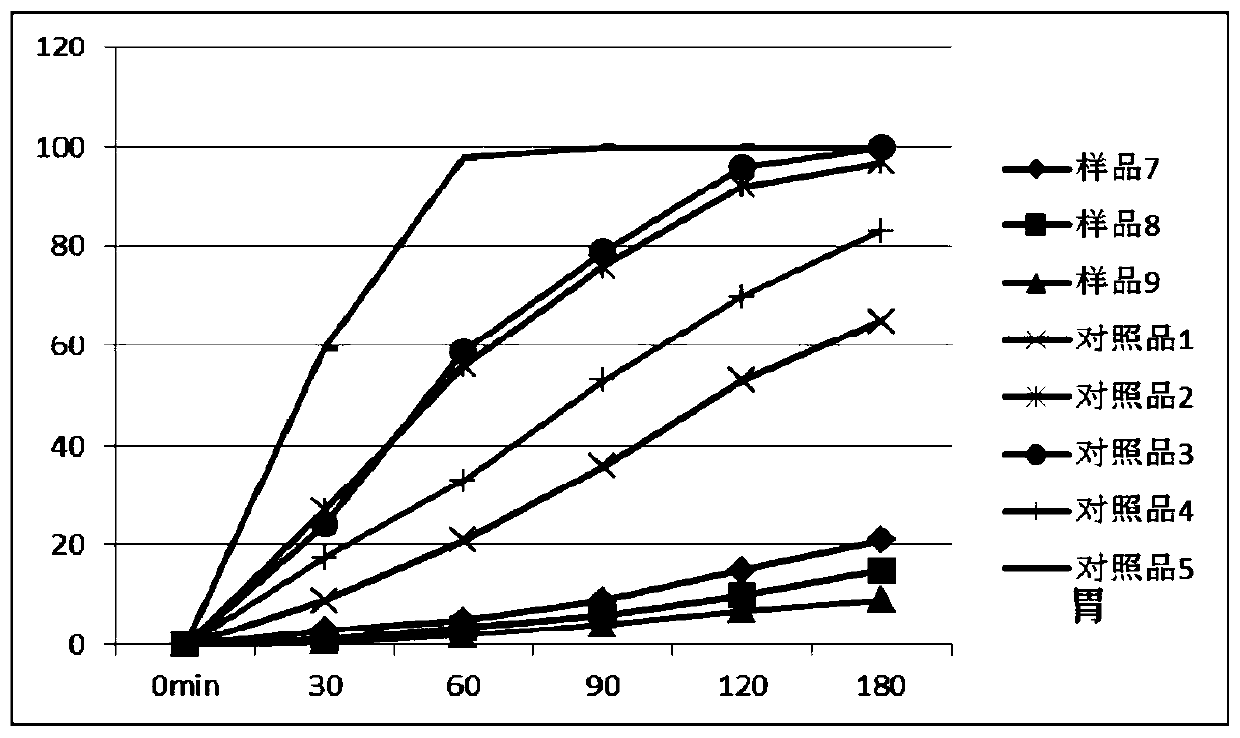

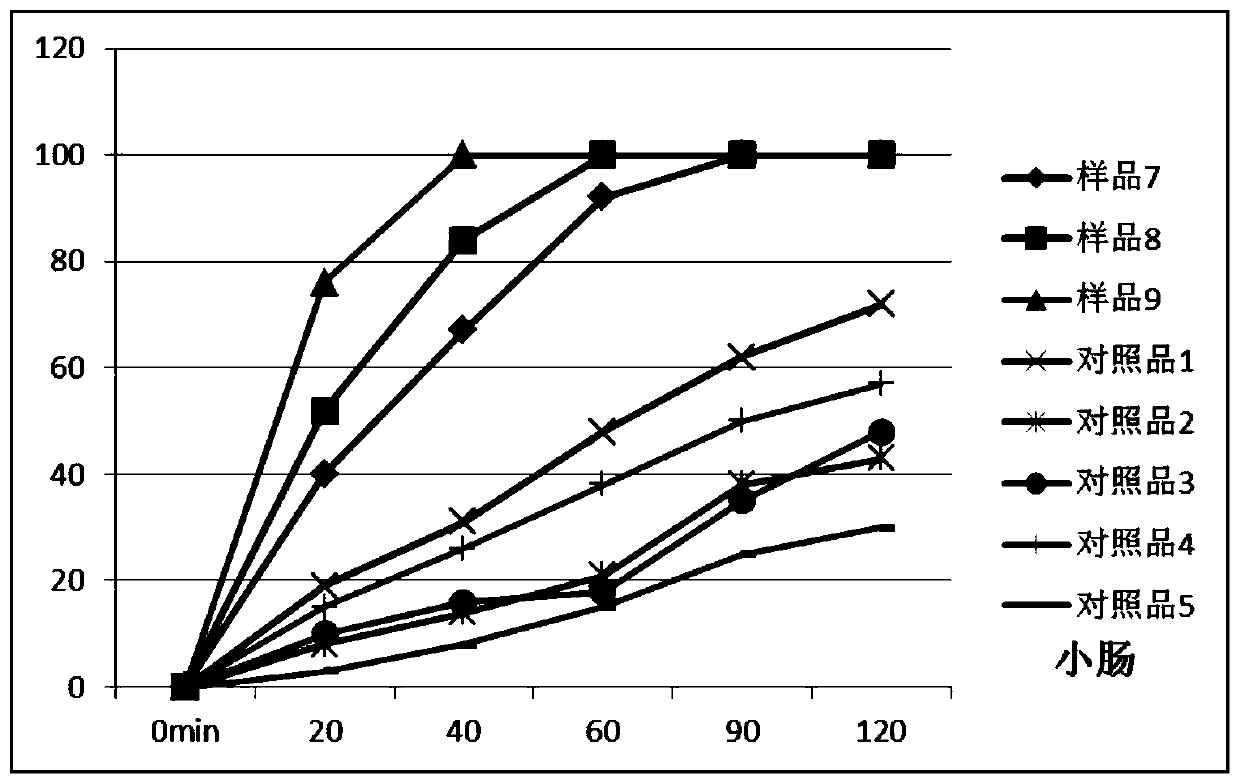

[0064] Example 3: pH-sensitive coenzyme Q 10 Preparation of gel microcapsules

[0065] Raw materials: see Table 3.

[0066] Table 3 Composition list of raw materials used

[0067]

[0068] *Sample 7 was prepared using ethanol as a solvent with a concentration of 0.3% (w / v) ethylcellulose-NH 4 OH solution;

[0069] *Sample 8 was prepared using ethanol as a solvent with a concentration of 1.2% (w / v) ethylcellulose-NH 4 OH solution;

[0070] *Sample 9 was prepared using ethanol as a solvent with a concentration of 2.5% (w / v) ethylcellulose-NH 4 OH solution.

[0071] Preparation:

[0072] 1. Put the above-mentioned alginate, stabilizer, auxiliary wall material, and purified water into the water phase tank according to a certain mass percentage, fully stir and mix, and raise the temperature to 54°C under normal pressure, and configure it as a water phase material;

[0073] 2. Put emulsified calcium salts, antioxidants, and fat-soluble nutrients into the oil phase tank ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com