Preparation method of novel metal-biochar-based hydrogenation catalyst and application thereof

A hydrogenation catalyst, biochar technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low conversion rate of hydrodeoxygenation and easy deactivation and other problems to achieve the effect of improving selectivity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of the present embodiment comprises the steps:

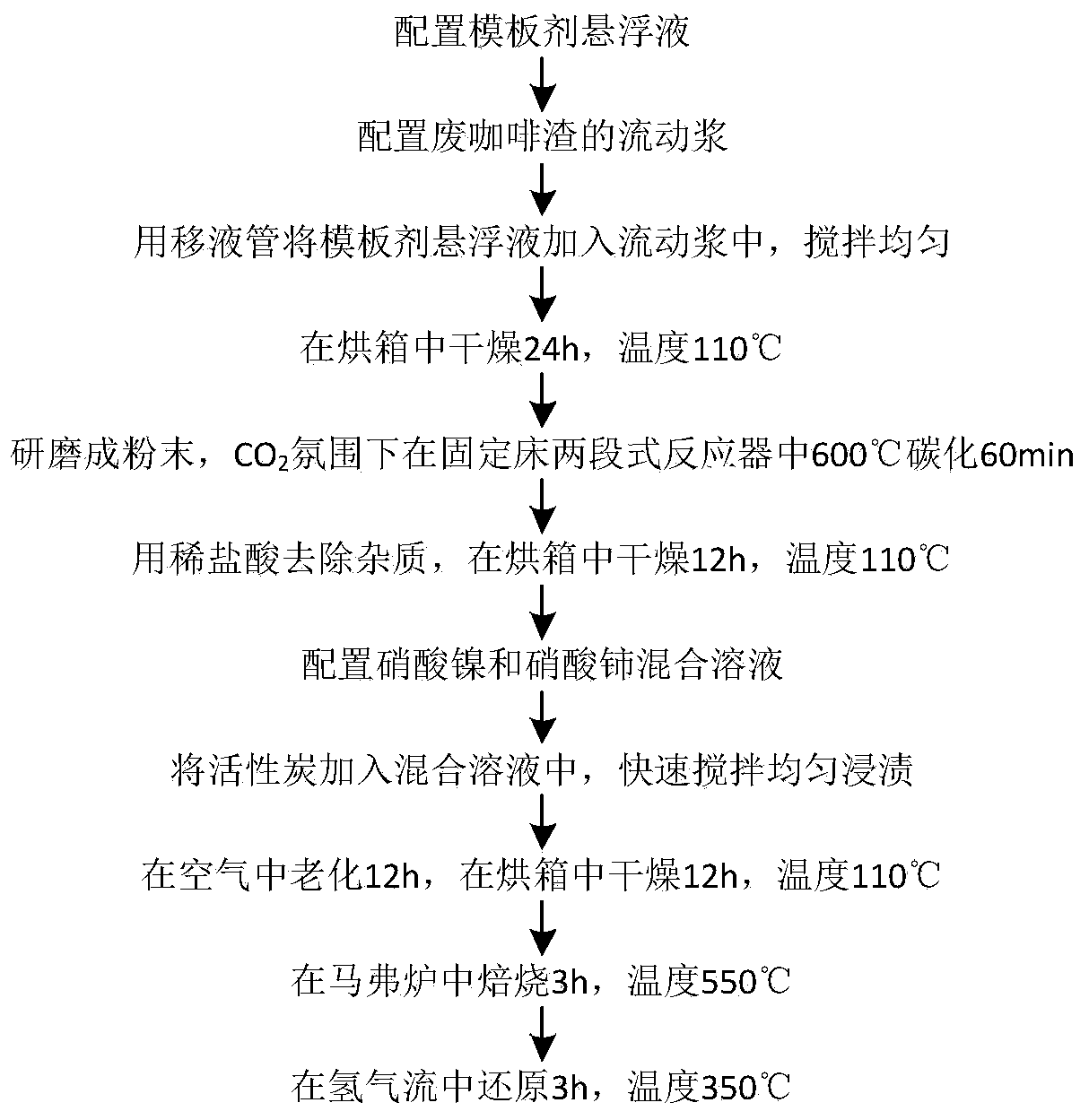

[0049] The preparation of a novel metal-biochar-based hydrogenation catalyst comprises the following steps, such as figure 1 Shown:

[0050] (1) Take the template agent, add deionized water to configure a certain concentration of the template agent suspension; wherein the template agent is a mixture of sodium alginate and cellulose nanofibers; the concentration of sodium alginate and cellulose nanofibers in the template agent suspension Both are 1.0wt%;

[0051] (2) Weigh 30g of degreased coffee grounds and place them in a beaker, add 150mL of deionized water to form a flowable slurry, add 100mL of templating agent suspension into the flowable slurry with a pipette, stir evenly and dry in an oven for 24 hours at a drying temperature of 110°C; grind the dried mixture into powder, CO 2 Carry out carbonization in a fixed-bed two-stage reactor under atmosphere, set the carbonization temperature at 60...

Embodiment 2

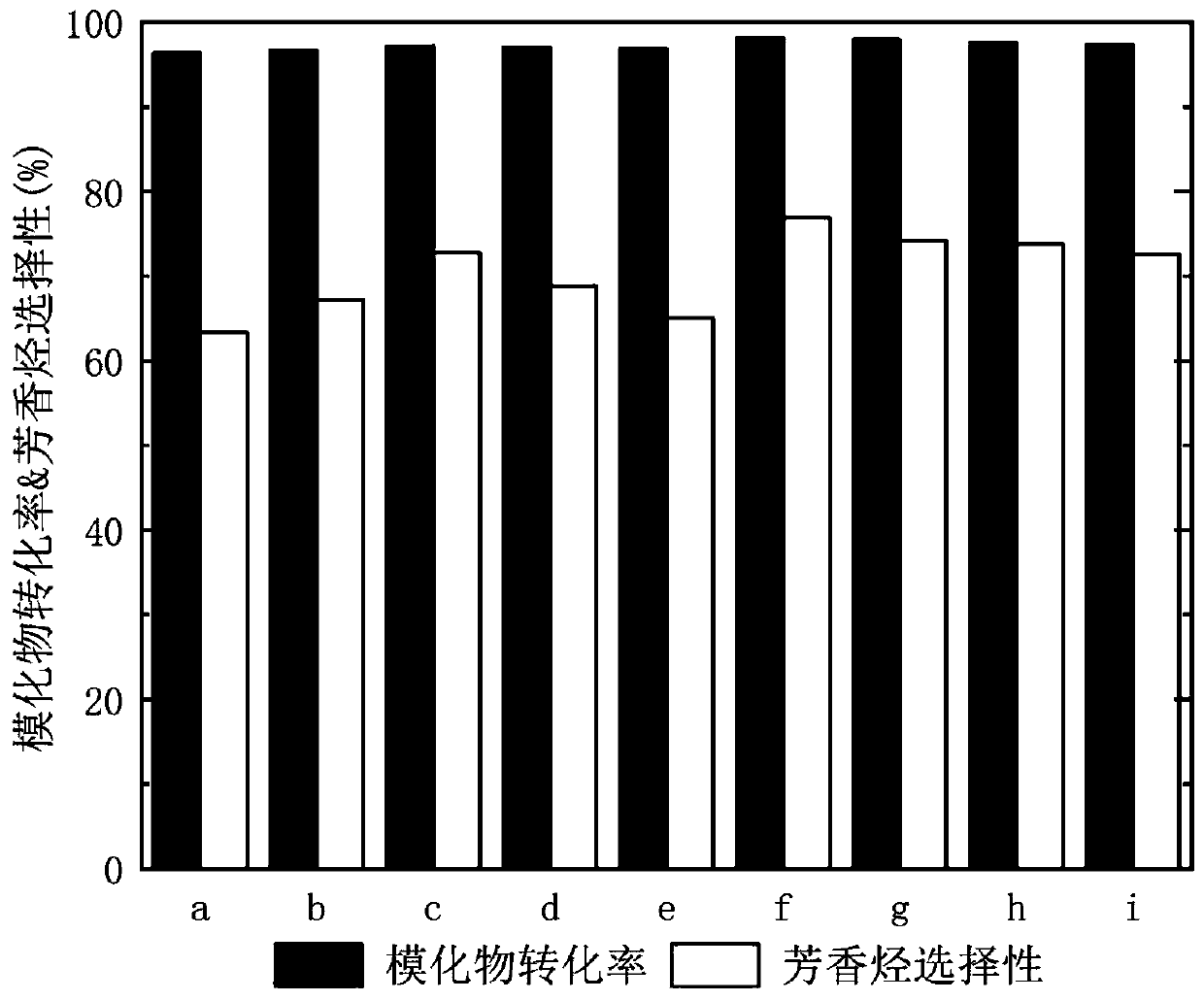

[0056] The preparation method of the novel metal-biochar-based hydrogenation catalyst is the same as in Example 1, the difference being that in step (5) activated carbon and Ni(NO 3 ) 2 and Ce(NO 3 ) 3 ·6H 2 The mass ratio of O is 100:18:4.

Embodiment 3

[0058] The preparation method of the novel metal-biochar-based hydrogenation catalyst is the same as in Example 1, the difference being that in step (5) activated carbon and Ni(NO 3 ) 2 and Ce(NO 3 ) 3 ·6H 2 The mass ratio of O is 100:24:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com