Surface treatment method for fiber reinforced composite material

A composite material and surface treatment technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low repetition rate, high cost, low efficiency, etc., to improve the bonding strength, achieve the effect of cleaning and activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

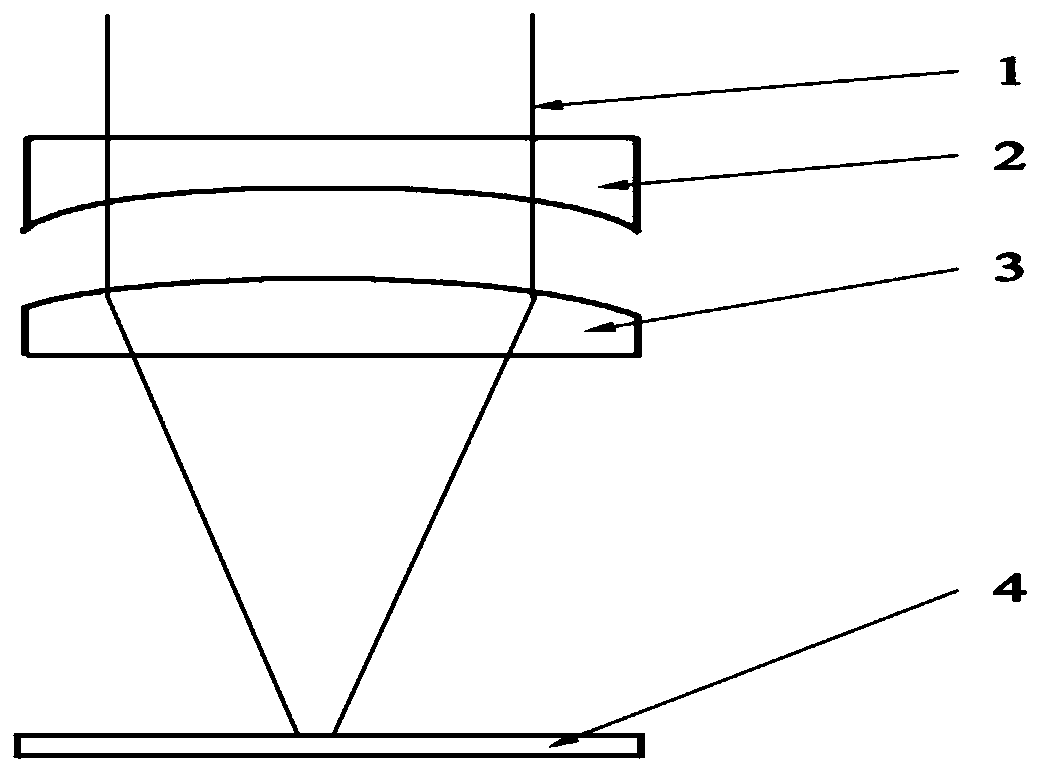

[0022] The embodiment of the present invention provides a method for surface treatment of fiber reinforced composite materials, see figure 1 , the method includes the following steps:

[0023] 1. Adjust two laser beams (femtosecond laser and nanosecond laser) to combine beams.

[0024] Select a beam of ultrashort pulse laser and a beam of nanosecond laser (both have the same pulse repetition frequency and wavelength) as the laser source, and combine the beams. In actual implementation, adjust the laser beam perpendicular to the sample according to the position of the sample surface in the actual application. surface.

[0025] Wherein, the laser wavelength is in the visible or infrared band. The ultrashort pulse laser usually has a pulse width of the order of femtoseconds, and the embodiment of the present invention does not limit the process of laser beam combining and collimation device adjustment.

[0026] 2. Homogenize the beam intensity of the combined laser beam 1

[...

Embodiment 2

[0032] The scheme in embodiment 1 is further introduced below in conjunction with specific examples, see the following description for details:

[0033] Install the sample 4 on the workbench or the displacement stage, and then select a beam of ultrashort pulse laser and a beam of nanosecond laser (with the same pulse repetition frequency and wavelength) as the laser source, combine the beams, and then pass through the beam shaping element 2 After homogenizing the light intensity, it converges vertically to the surface of sample 4.

[0034] The ultrashort pulse laser adopts a pulse width of 10-10000 femtoseconds, a repetition frequency of 0.001-50MHz, and a power of 1-100W. When the ultrashort pulse laser intensity is greater than or equal to the multiphoton absorption threshold light intensity on the surface of the composite material, multiphoton absorption occurs on the surface of sample 4 within the laser irradiation range, and the nanosecond laser energy is absorbed until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com