Preparation method of hollow mesoporous silica nano microspheres

A technology of mesoporous silica and nano-microspheres, applied in the directions of silica, silica, nanotechnology, etc., can solve the problems of complex preparation method and serious agglomeration of hollow mesoporous nanospheres, and achieve simple and heavy-duty preparation methods. Good performance and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

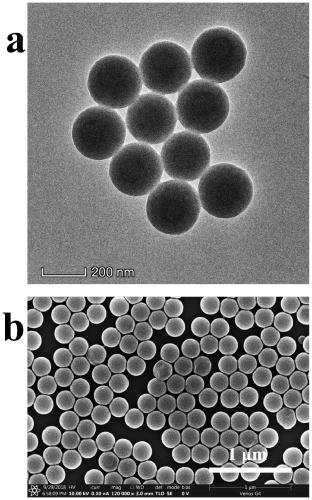

[0027] (1) Add 10g of styrene and 1.5g of polypyrrolidone into 100mL of aqueous solution and stir thoroughly, then add 0.26g of 2,2'-azobis(2-methylpropylimidium) dihydrochloride to the above mixed solution , the process was protected by nitrogen and stirred at room temperature for 60 minutes, then the reaction temperature was raised to 70 ° C, and PS balls were obtained after 24 hours of reaction; the stirring rate was 100-200 r / min; the PS balls were washed three times with water and ethanol , dried under vacuum at 45°C.

[0028] (2) Add 0.3335 g of PS spheres to 45 mL of ethanol solution, and disperse by ultrasonic for 5-10 min, then transfer the mixed solution of PS spheres to a magnetic stirring device and start stirring; the ultrasonic power is 60W.

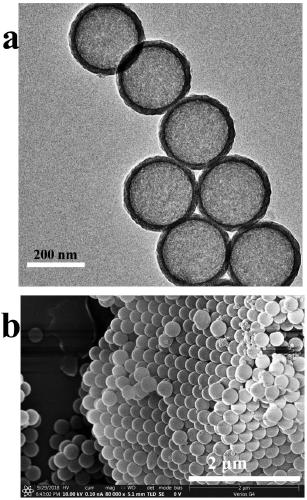

[0029] (3) Add 2g TEOs to the solution (2), and immediately add 2.4mL ammonia water, and heat in a water bath at 50°C for 3h to obtain PS@SiO 2 nanospheres; resulting PS@SiO 2 The nano-microspheres are washed three times ...

Embodiment 2

[0033] (1) Add 10g styrene and 1.5g polypyrrolidone into 100mL aqueous solution and stir thoroughly, then add 0.26g of 2,2'-azobis(2-methylpropylimidium) dihydrochloride to the above mixed solution , the process was protected by nitrogen and stirred at room temperature for 60 minutes, then the reaction temperature was raised to 70 ° C, and PS balls were obtained after 24 hours of reaction; the stirring rate was 100-200 r / min; the PS balls were washed three times with water and ethanol , dried under vacuum at 45°C.

[0034] (2) Add 0.3335 g of PS spheres to 45 mL of ethanol solution, and disperse by ultrasonic for 5-10 min, then transfer the mixed solution of PS spheres to a magnetic stirring device and start stirring; the ultrasonic power is 60W.

[0035] (3) Add 1.2g of TEOs to (2) solution, and immediately add 5.6mL of ammonia water, and heat in a water bath at 50°C for 1.5h to obtain PS@SiO 2 nanospheres; resulting PS@SiO 2 The nano-microspheres are washed three times wit...

Embodiment 3

[0039] (1) Add 10g styrene and 1.5g polypyrrolidone into 100mL aqueous solution and stir thoroughly, then add 0.26g of 2,2'-azobis(2-methylpropylimidium) dihydrochloride to the above mixed solution , the process was protected by nitrogen and stirred at room temperature for 60 minutes, then the reaction temperature was raised to 70 ° C, and PS balls were obtained after 24 hours of reaction; the stirring rate was 100-200 r / min; the PS balls were washed three times with water and ethanol , dried under vacuum at 45°C.

[0040] (2) Add 0.3335 g of PS spheres to 45 mL of ethanol solution, and disperse by ultrasonic for 5-10 min, then transfer the mixed solution of PS spheres to a magnetic stirring device and start stirring; the ultrasonic power is 60W.

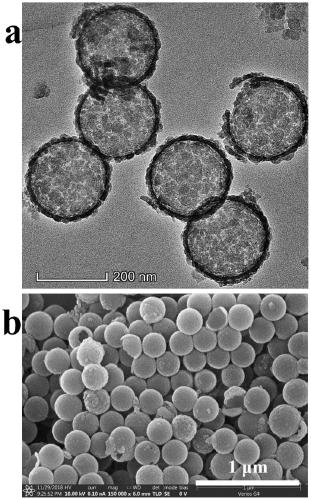

[0041] (3) Add 1 g of TEOs to the solution (2), and immediately add 2.24 mL of ammonia water, and heat in a water bath at 50 °C for 1.5 h to obtain PS@SiO 2 nanospheres; resulting PS@SiO 2 The nano-microspheres are washed three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com