Preparation method of anorthite-quartz-glass phase composite ceramic

A technology of composite phase ceramics and glass phase, applied in the field of composite ceramics, can solve the unavoidable problems of high thermal expansion coefficient, low strength, low strength, high sintering temperature, etc., and achieve the effect of abundant raw materials, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

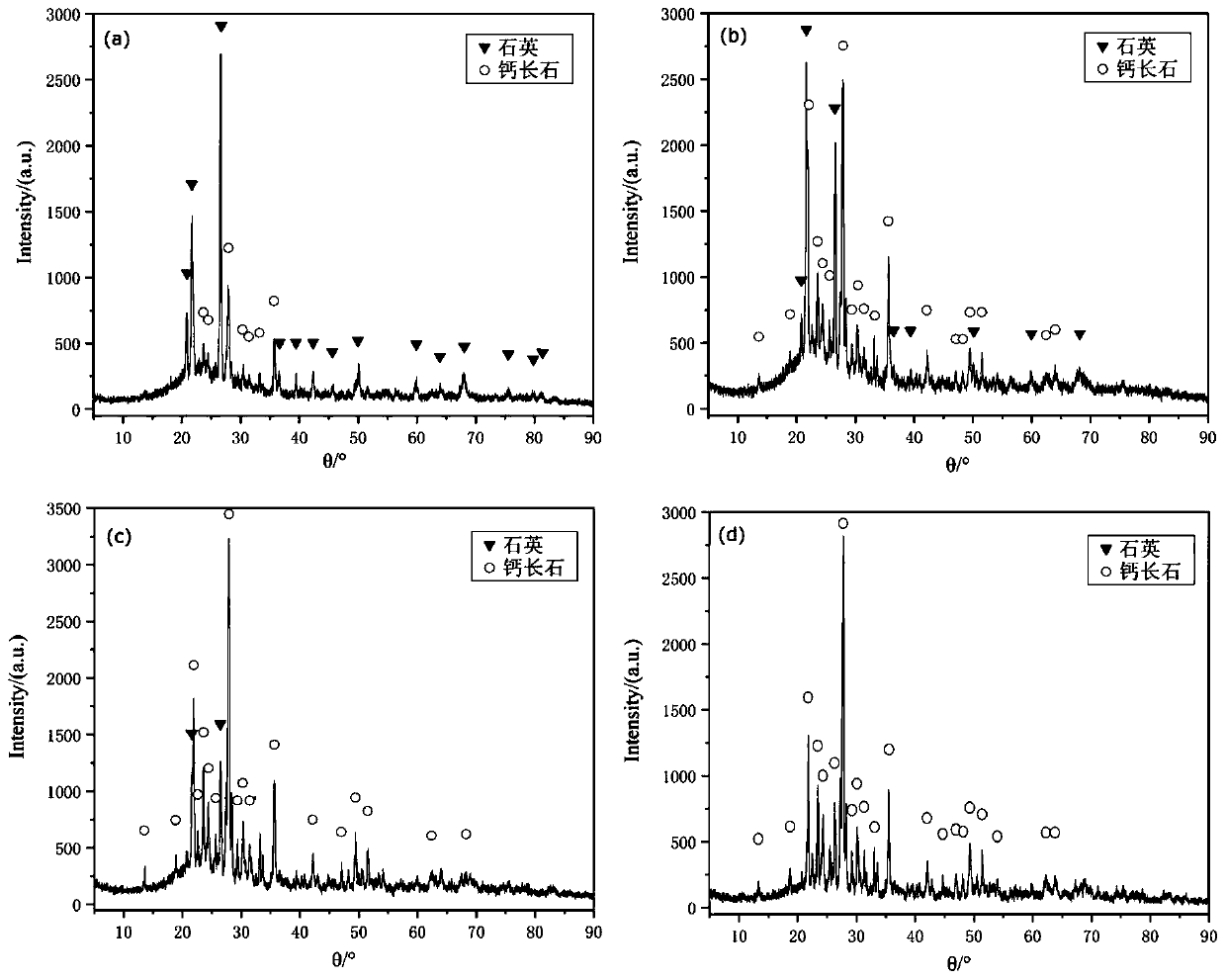

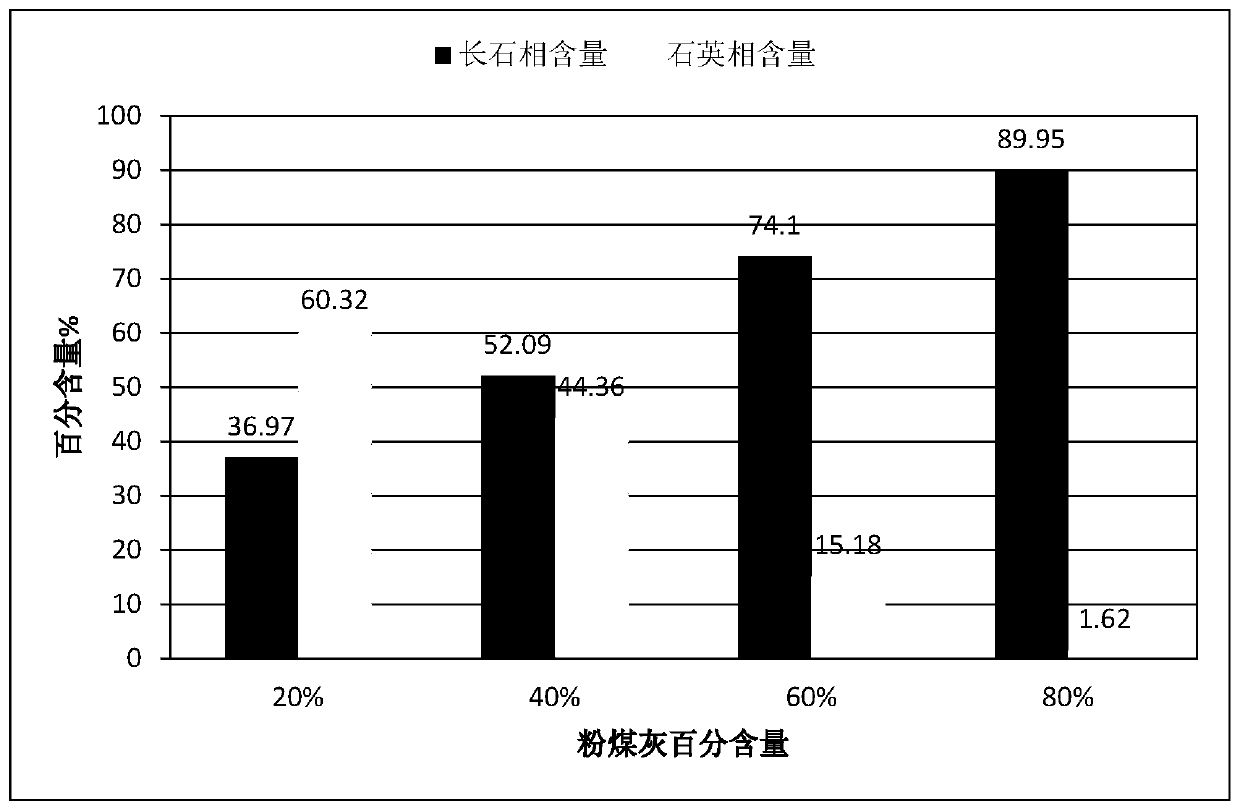

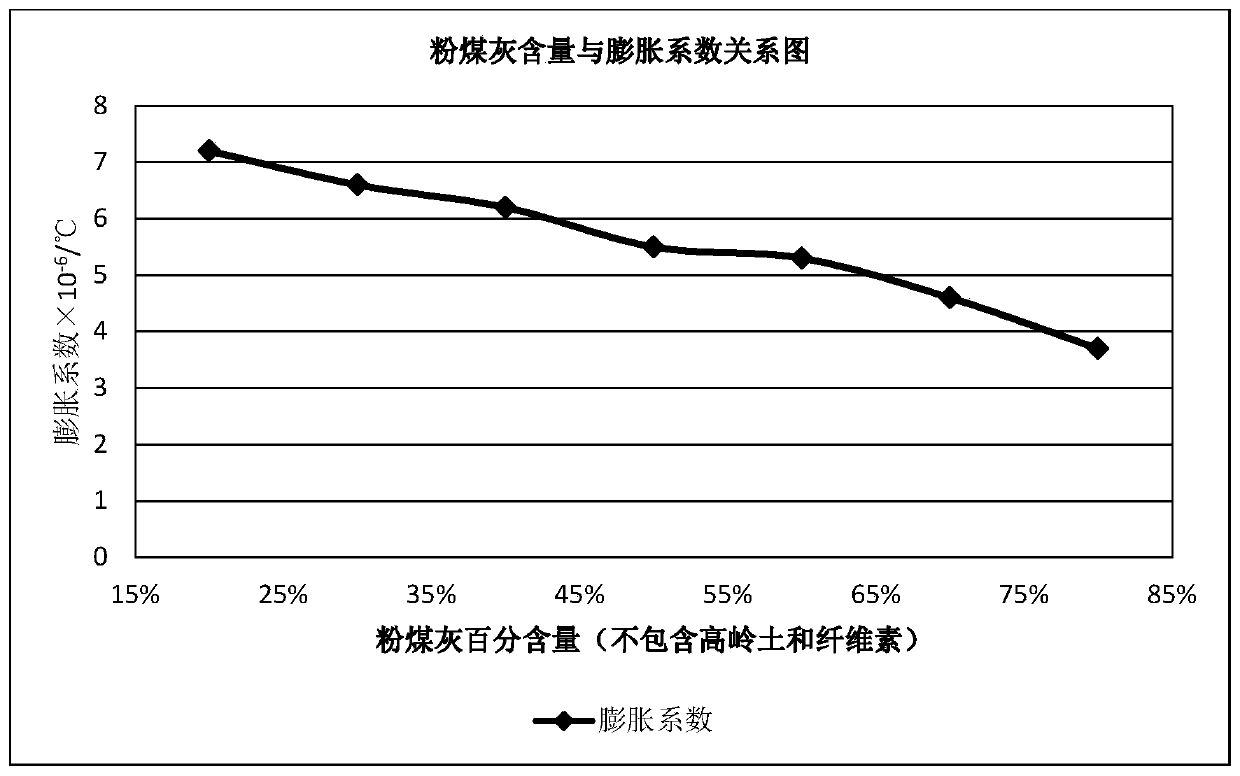

Embodiment 1

[0033] The mass ratio of desert sand, fly ash, kaolin and cellulose is 8:2:0.5:1. Mix desert sand, fly ash, kaolin and cellulose and ball mill in water. The amount of water used is 50% of the total mass of raw materials. %; the time of ball milling is 3 hours, the speed of ball milling is 40 rpm, the particle size of powder after ball milling is 5-10 μm, the particle size of granulation is 1-2mm, molding under 20MPa pressure, sintering at 1100 ° C for 2 hours, The apparent porosity of the ceramic is 6.8%, the bending strength is 70MPa, and the thermal expansion coefficient is 7.2×10 -6 / °C.

Embodiment 2

[0035] The mass ratio of desert sand, fly ash, kaolin and cellulose is 7:3:1:1.5. Mix desert sand, fly ash, kaolin and cellulose and ball mill in water. The amount of water is 50% of the total mass of raw materials. %; the time of ball milling is 2 hours, the speed of ball milling is 40 rpm, the particle size of the powder after ball milling is 5-10 μm, the particle size of granulation is 1-2mm, molding under 30MPa pressure, sintering at 1150 ° C for 4 hours, The apparent porosity of the ceramic is 4.9%, the bending strength is 97MPa, and the thermal expansion coefficient is 6.6×10 -6 / °C.

Embodiment 3

[0037]The mass ratio of desert sand, fly ash, kaolin and cellulose is 6:4:2:1. After mixing desert sand, fly ash, kaolin and cellulose, they are ball milled in water. The amount of water is 50% of the total mass of raw materials. %; the time of ball milling is 2.5 hours, the speed of ball milling is 40 rpm, the particle size of the powder after ball milling is 5-10 μm, the particle size of granulation is 1-2mm, molding under 50MPa pressure, and sintering at 1250 ° C for 3 hours, The apparent porosity of the ceramic is 0.5%, the bending strength is 110MPa, and the thermal expansion coefficient is 6.2×10 -6 / °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com