Preparation method of novel phosphate group-containing melamine-formaldehyde oligomer type migratory steel bar corrosion inhibitor

A technology of steel rust inhibitor and melamine, which is applied in the field of preparation of melamine-formaldehyde oligomer-type migratory steel rust inhibitor, can solve the problem of the surrounding environment and human health harmful industrial waste gas, and the limited source of raw materials for migratory rust inhibitors , expensive materials and other issues, to achieve the effect of improving long-term resistance to chloride ion erosion, good protection, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

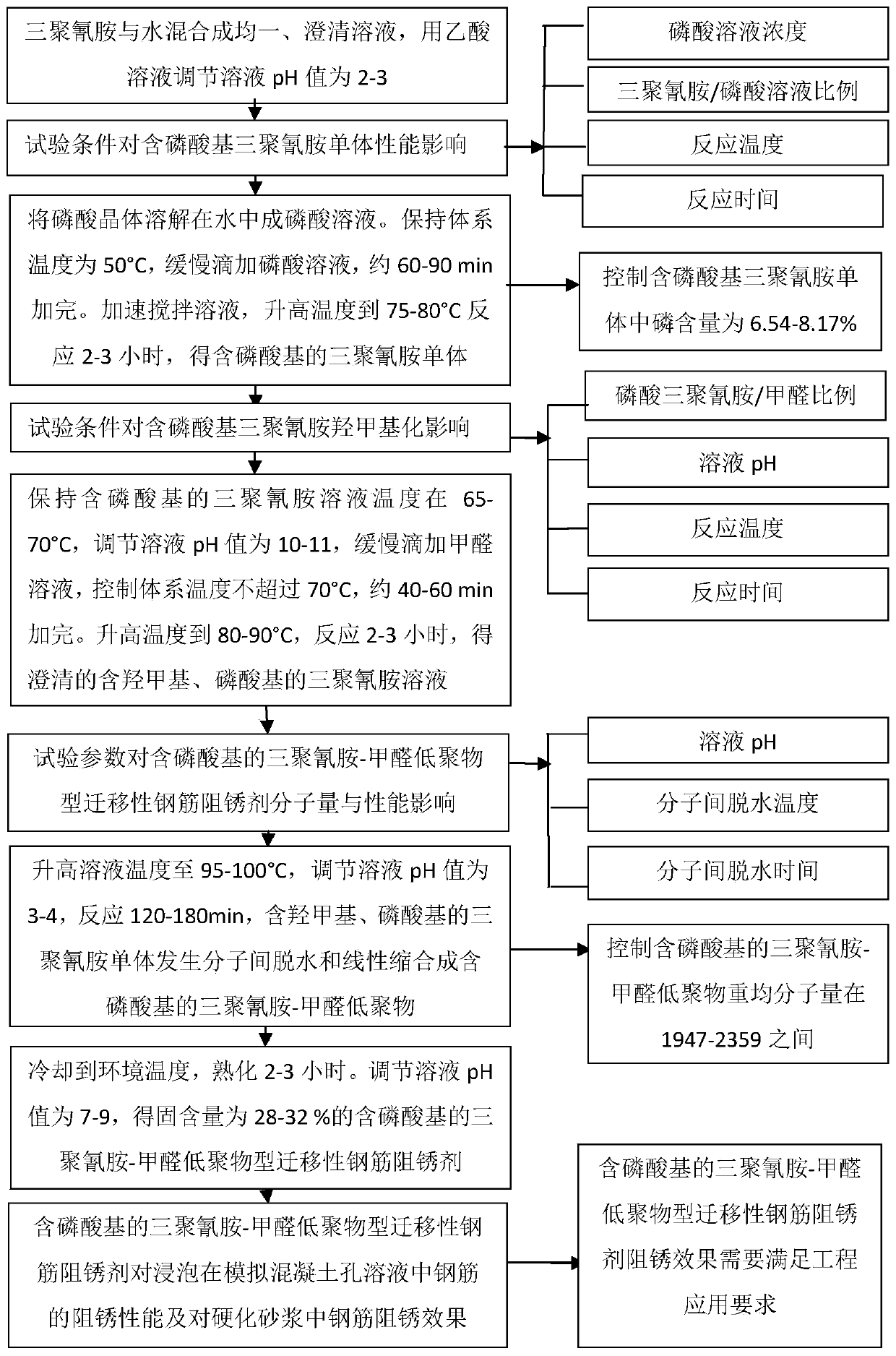

Method used

Image

Examples

Embodiment 1

[0043] 1.1. Preparation of melamine solution

[0044] Weigh 400kg of solid melamine and 550kg of water and put it into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel and a reflux condenser. The mixture was continuously stirred to make melamine completely dissolved in water to form a homogeneous and clear solution, and then acetic acid with a concentration of 36% by weight was added to adjust the pH of the solution to 2.

[0045] 1.2. Preparation of phosphoric acid-containing melamine monomers

[0046] 145kg of white crystalline phosphoric acid was dissolved in 218kg of water to form a phosphoric acid solution with a concentration of 40% by weight. Slowly add 363kg phosphoric acid solution dropwise to the melamine solution of 517kg, keep stirring the solution, control the temperature of the system not to exceed 50°C, add about 60min, raise the mixed solution temperature to 75°C after adding, and react at this temperature for 2 hours, Finally, a ho...

Embodiment 2

[0052] 1.1. Preparation of melamine solution

[0053] Weigh 450kg of solid melamine and 600kg of water and put them into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel and a reflux condenser. The mixture was continuously stirred to make melamine completely dissolved in water to form a homogeneous and clear solution, and then acetic acid with a concentration of 38% by weight was added to adjust the pH of the solution to 3.

[0054] 1.2. Preparation of phosphoric acid-containing melamine monomers

[0055] Dissolve 146 kg of white crystalline phosphoric acid in 220 kg of water to form a phosphoric acid solution with a concentration of 40% by weight. Slowly add 366kg phosphoric acid solution dropwise to the melamine solution of 519kg, keep stirring the solution, control the temperature of the system not to exceed 50 ° C, add about 90 min, increase the temperature of the mixed solution to 80 ° C after adding, and react at this temperature for 3 hours, ...

experiment example 1

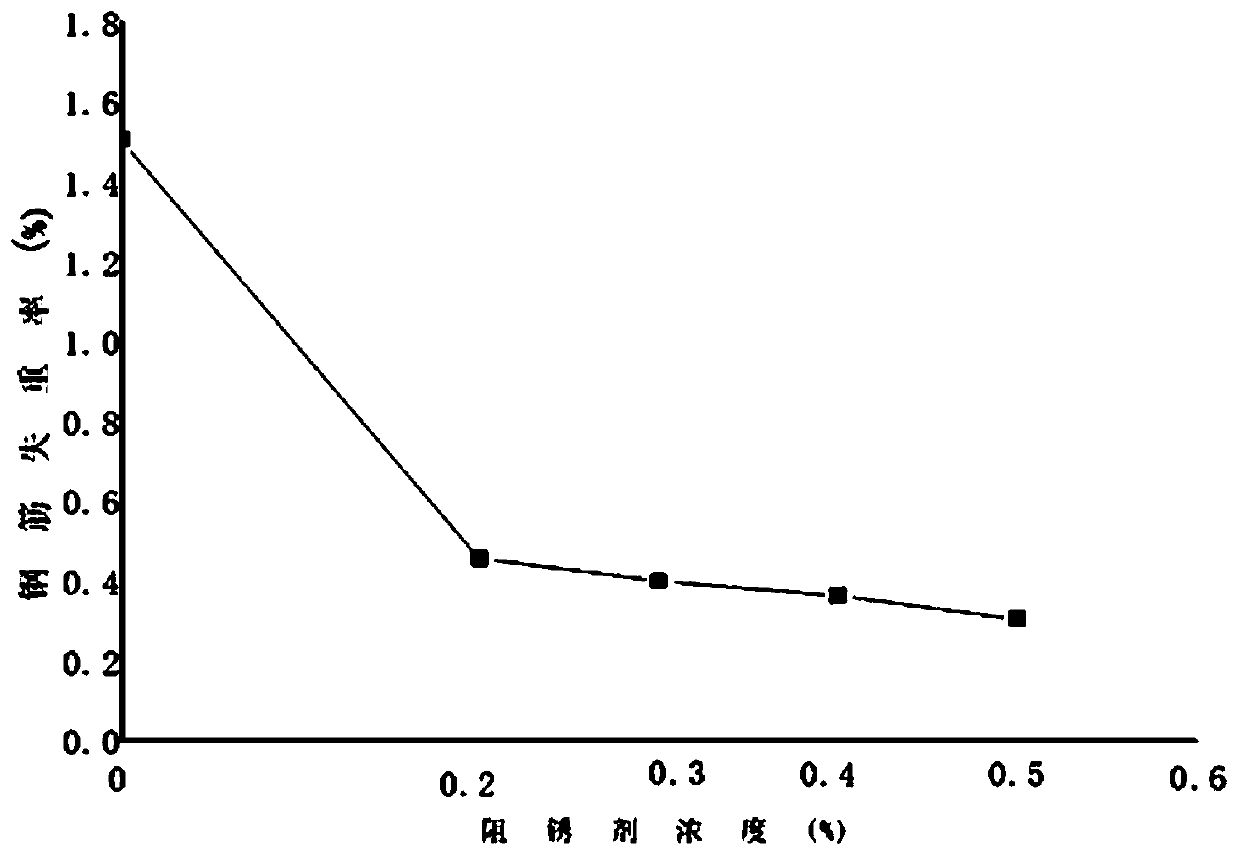

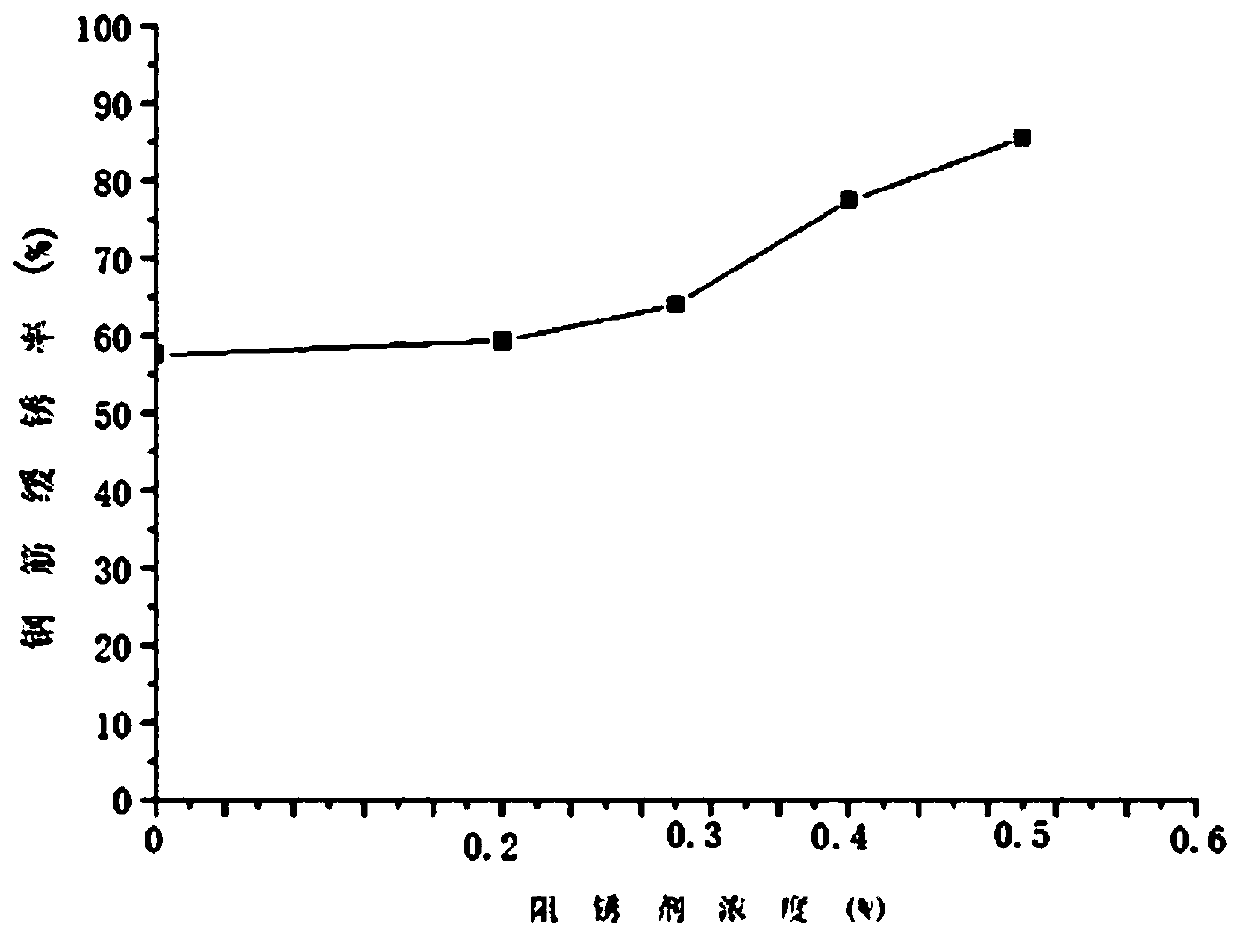

[0061] Determination of rust-inhibiting effect of simulated concrete hole solution of phosphoric acid group-containing melamine-formaldehyde oligomer type migratory steel bar rust inhibitor with different dosages

[0062] 2.1. Preparation of steel bar samples

[0063] Referring to the test method of ASTM G3172, the diameter of Φ6mm and the length of 100mm is used to process the Q235 round steel bar for construction into a steel bar with a diameter of Φ6mm and a length of about 90mm, and the surface of the steel bar is removed by grinding with 100-1000 mesh SiC water sandpaper and 200 mesh metallographic sandpaper. After the oxide skin, it becomes a steel bar with a smooth surface for use.

[0064]2.2. To study the rust-inhibiting effect of the phosphoric acid group-containing melamine-formaldehyde oligomer type migratory steel bar rust inhibitor in the simulated concrete pore solution. The simulated concrete pore solution used in this study was 3.0% NaCl and (saturated Ca(OH)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com