A kind of preparation method of alumina-yag eutectic melt growth composite material

A composite material and melt growth technology, which is applied in the direction of directional solidification, crystal growth, single crystal growth, etc. The problem of equal composition can achieve the effect of high relative density and texture, avoiding thermoelastic stress and uniform phase distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides an Al 2 o 3 -The preparation method of YAG eutectic melt growth composite material, comprises the following steps:

[0036] (1) Al 2 o 3 Powder and Y 2 o 3 The powder is ball-milled and then dried in the presence of a binder and an alcoholic solvent to obtain a mixed powder;

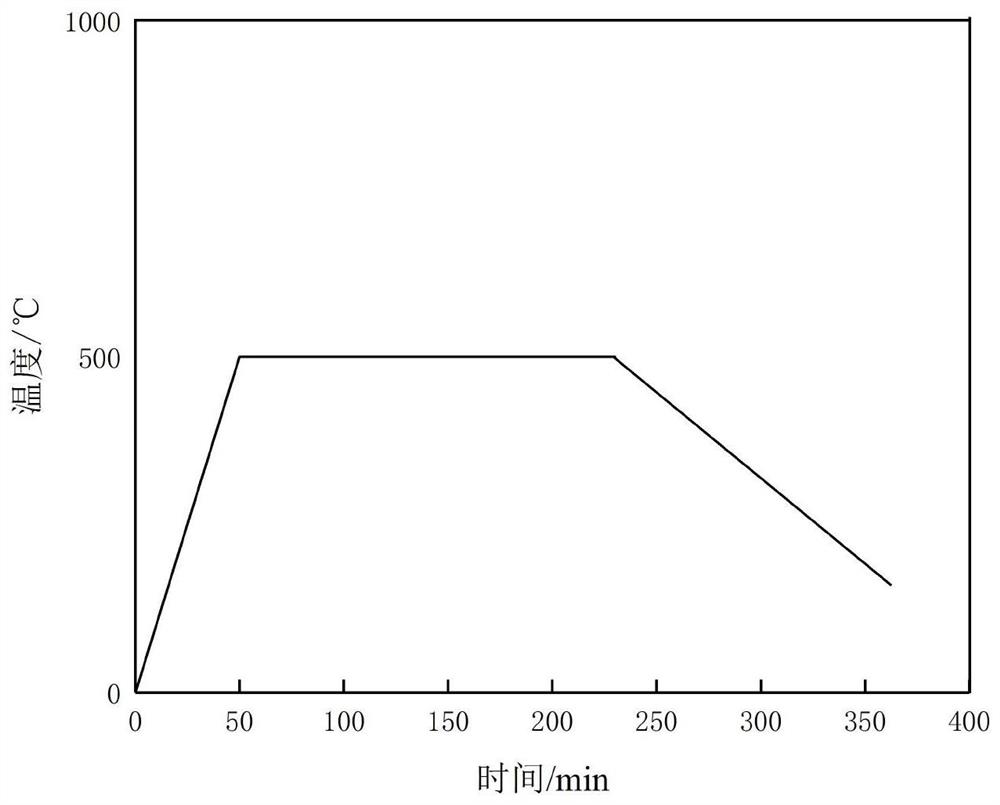

[0037](2) The mixed powder is sequentially subjected to pressing and sintering and then cooled to obtain a preform;

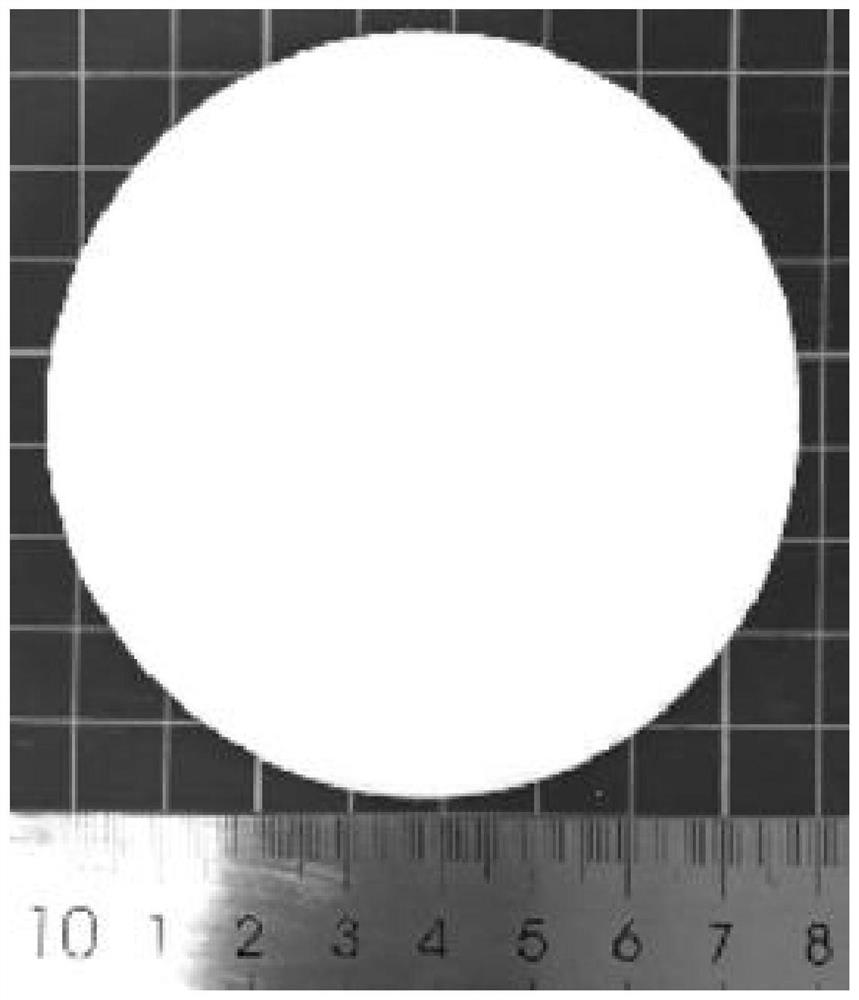

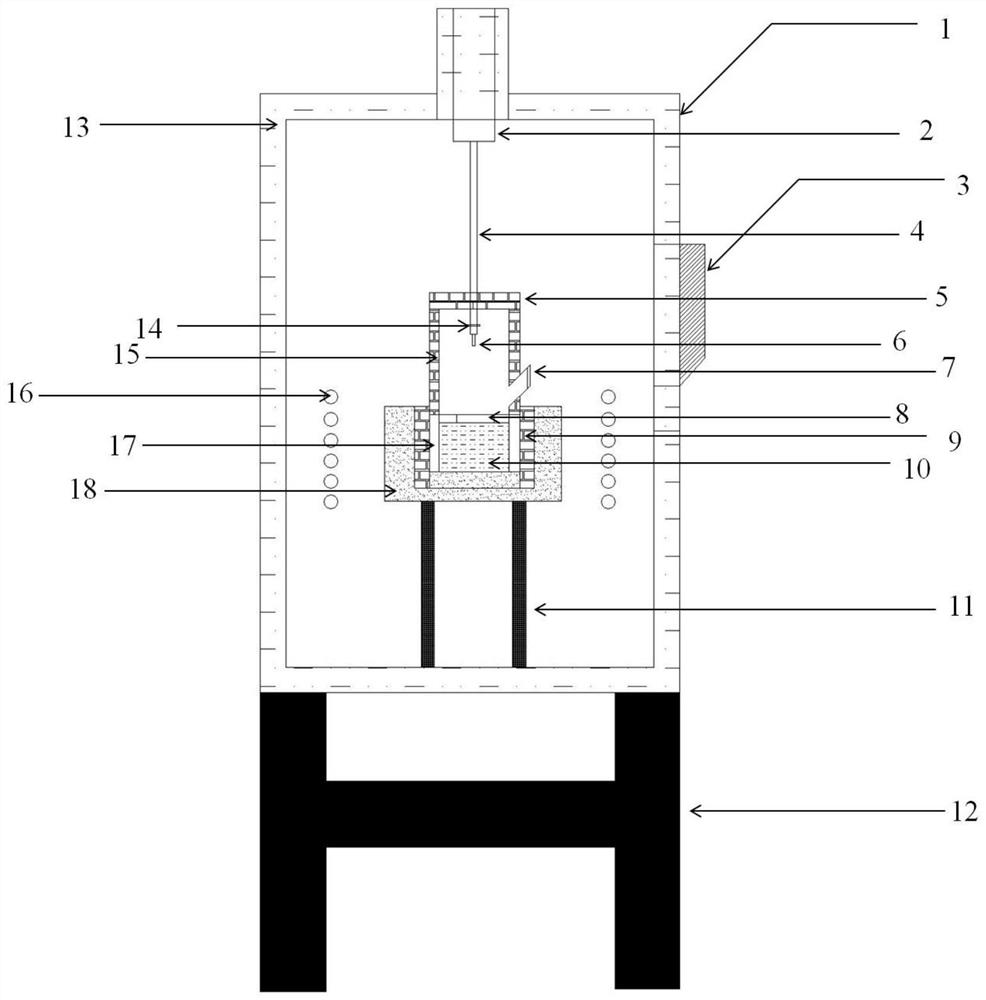

[0038] (3) In the temperature field, the seed crystal is immersed in the melt of the preform by using the rotating pulling method, and then undergoes seeding, necking, shouldering, equal diameter growth and finishing in sequence to obtain Al 2 o 3 - YAG eutectic melt growth composite material;

[0039] The seeding temperature is 1770-1780° C., the pulling speed is 0.1-5 mm / h, and the rotation speed is 5-25 r / min.

[0040] The present invention will Al 2 o 3 Powder and Y 2 o 3 The powder is ball milled and then dried in the presence of a binder an...

Embodiment 1

[0060] (1) Select high-purity micron grade Al 2 o 3 (99.99% pure), Y 2 o 3 (purity 99.99%) powder by Al 2 o 3 / Y 2 o 3 =81.5 / 18.5 molar ratio to prepare raw materials, where Al 2 o 3 The particle size of the powder is 1~2μm, Y 2 o 3 The particle size of the powder is 1-2 μm. First put the original powder in a drying oven at 90°C for 3 hours, and then use an electronic balance to weigh 100g of Al according to the above ratio. 2 o 3 and Y 2 o 3 powder, put the above powder into a ball mill jar for ball milling, and add 20mL polyvinyl alcohol binder and 60mL absolute ethanol to the ball mill jar at the same time, wherein the polyvinyl alcohol binder consists of polyvinyl alcohol and water, and polyvinyl alcohol and water The dosage ratio is 1g:20mL, ball milling starts after standing for 5min, the ball milling medium is zirconia, the ball-to-material ratio is 2:1, the ball milling speed is 550r / min, and the ball milling time is 6h to obtain a powder slurry; then the ...

Embodiment 2

[0067] (1) Select high-purity micron grade Al 2 o 3 (99.99% pure), Y 2 o 3 (purity 99.99%) powder by Al 2 o 3 / Y 2 o 3 =81.5 / 18.5 molar ratio to prepare raw materials, where Al 2 o 3 The particle size of the powder is 1~2μm, Y 2 o 3 The particle size of the powder is 1-2 μm. First put the original powder in a drying oven at 90°C for 3 hours, and then use an electronic balance to weigh 100g of Al according to the above ratio. 2 o 3 and Y 2 o 3 powder, put the above powder into a ball mill jar for ball milling, and add 20mL polyvinyl alcohol binder and 60mL absolute ethanol to the ball mill jar at the same time, wherein the polyvinyl alcohol binder consists of polyvinyl alcohol and water, and polyvinyl alcohol and water The dosage ratio is 1g:20mL, and ball milling starts after standing for 5min. The ball milling medium is zirconia, the ball-to-material ratio is 3:1, the ball milling speed is 550r / min, and the ball milling time is 6h to obtain a powder slurry; then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com