Surface modification method for thin titanium bipolar plate of proton exchange membrane fuel cell

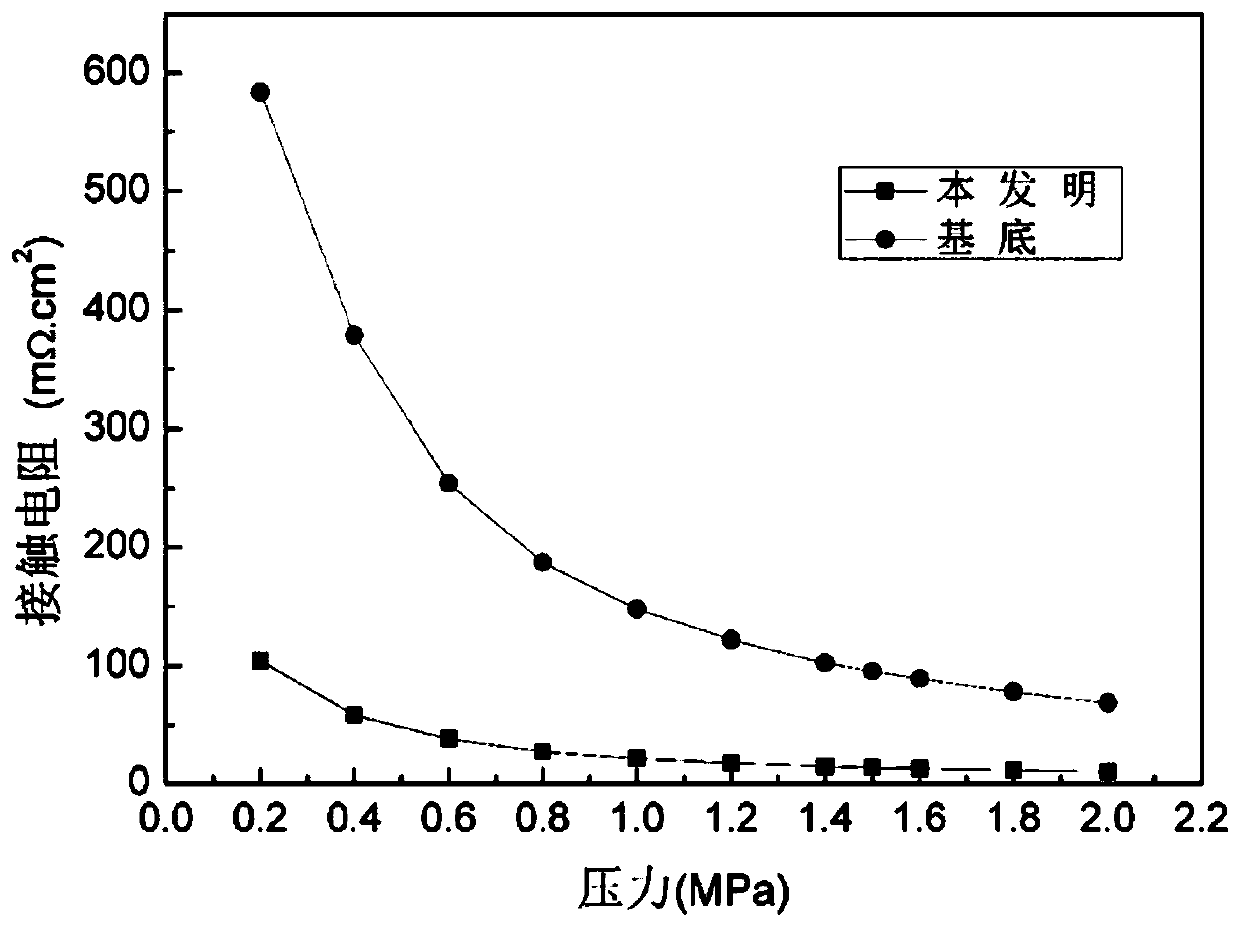

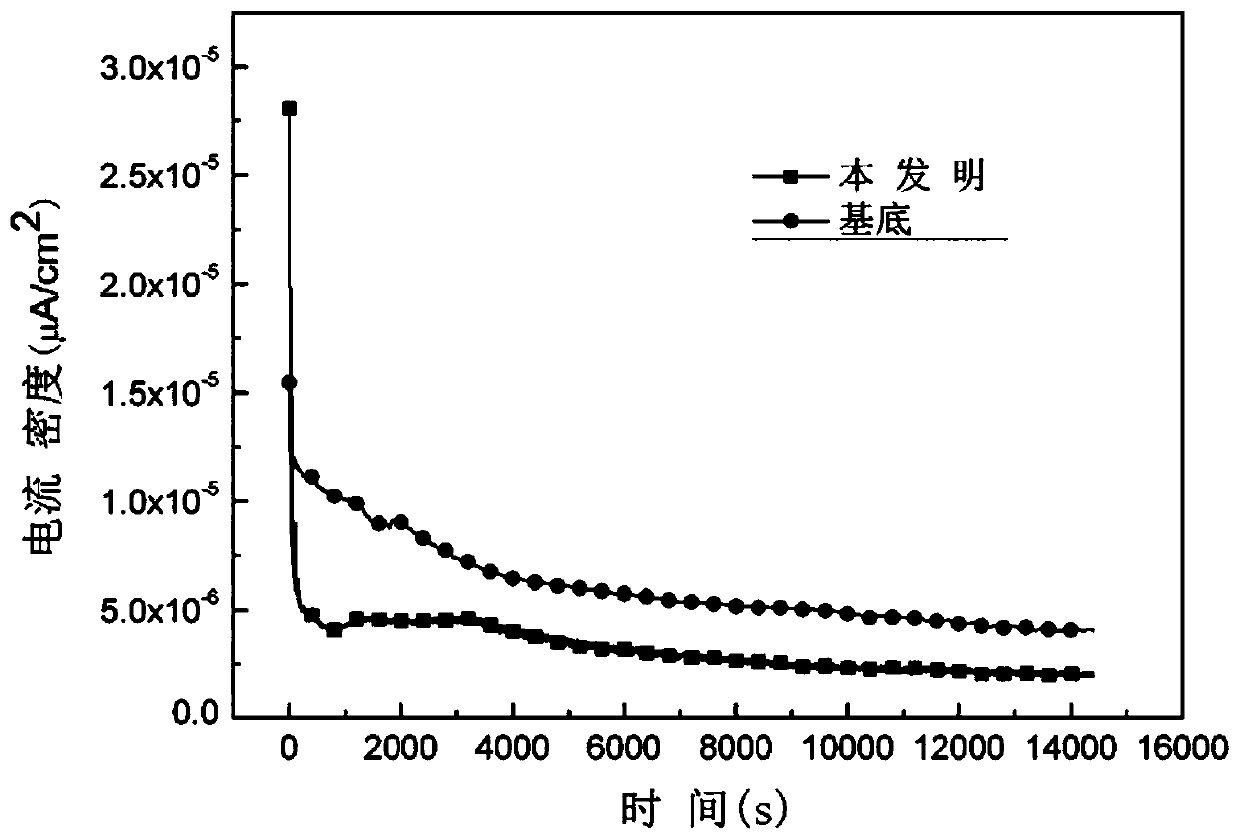

A proton exchange membrane and fuel cell technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve the problems of low film formation efficiency, high material loss, and poor stability of carbon coatings, and achieve membrane layer bonding Good, improved corrosion resistance, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method comprises the following steps:

[0020] (1) Industrial pure titanium substrate, with a thickness of 0.05-0.5mm;

[0021] (2) Use detergent to wash off the large pieces of oil and dust on the surface of the titanium plate. After rinsing with deionized water, sonicate in acetone for 15-30 minutes to remove the residual oil, and then place it in oxalic acid solution at 70-100°C for 1-2 hours. Activate the surface to remove the passivation layer and improve the bonding force with the coating;

[0022] (3) The entire coating process is carried out in a high vacuum environment. First, the vacuum is roughly pumped to 1-3Pa, then the rough pumping system is turned off, and the fine pumping is turned on to 2x10 -3 ~2x10 -2 Pa, and then argon to maintain the flow rate of 100 ~ 500sccm to start coating;

[0023] (4) Turn on the target power supply, keep the current at 10-30A, control the bias voltage at -1000--500V, and clean the sputtering for 10-30 minu...

Embodiment 1

[0028] Use TA1 industrial pure titanium as the substrate, with a size of 20x60x0.1mm. After being ultrasonically treated with acetone for half an hour and oxalic acid at 80°C for one hour, it is placed in a vacuum chamber and vacuumed to 3x10 -3 Pa, the flow rate of argon is maintained at 300 sccm to start deposition. Turn on the bias voltage to -600V, turn on the Nb metal target, adjust the current to 30A, and perform cleaning and sputtering for 10 minutes; adjust the bias voltage to -300V to deposit the coating, adjust the current to 70A, and continue for 30 minutes to obtain the modified Nb Coated titanium bipolar plates.

Embodiment 2

[0030] Use TA1 industrial pure titanium as the substrate, with a size of 20x60x 0.2mm. After being ultrasonically treated with acetone for half an hour and oxalic acid at 80°C for one hour, it is placed in a vacuum chamber and evacuated to 3x10 -3 Pa, the flow rate of argon is maintained at 300 sccm to start deposition. Turn on the bias voltage to -700V, turn on the Cr metal target, adjust the current to 40A, and perform cleaning and sputtering for 20 minutes; adjust the bias voltage to -300V to deposit the coating, adjust the current to 85A, and continue for 45 minutes to obtain the modified Cr Coated titanium bipolar plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com