Food microwave 3D printing equipment, system and printing method

A 3D printing and microwave technology, applied in microwave heating, food forming, food coating, etc., can solve problems such as inability to print three-dimensional complex shapes, insufficient mechanical strength, material flow, etc., to reduce the volume of the heating chamber and improve the Effect of improving molding quality and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

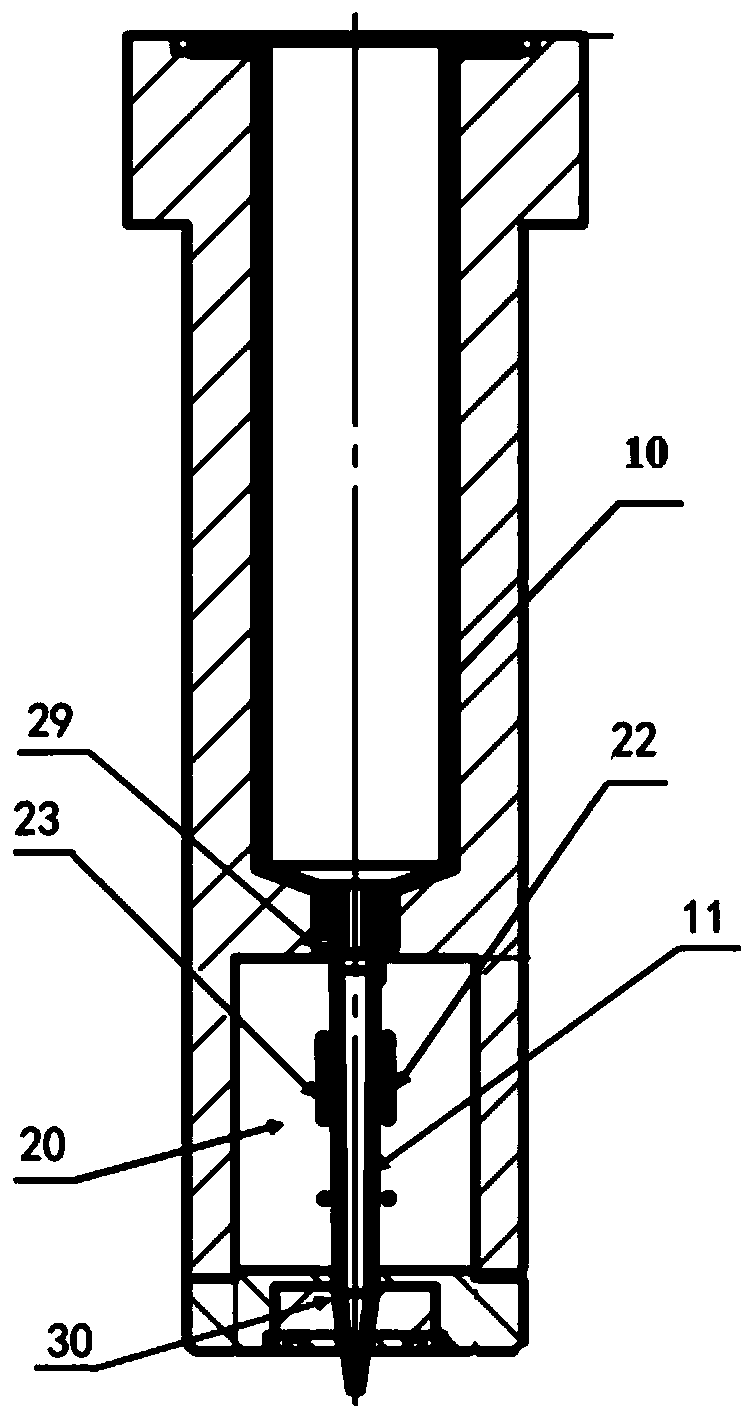

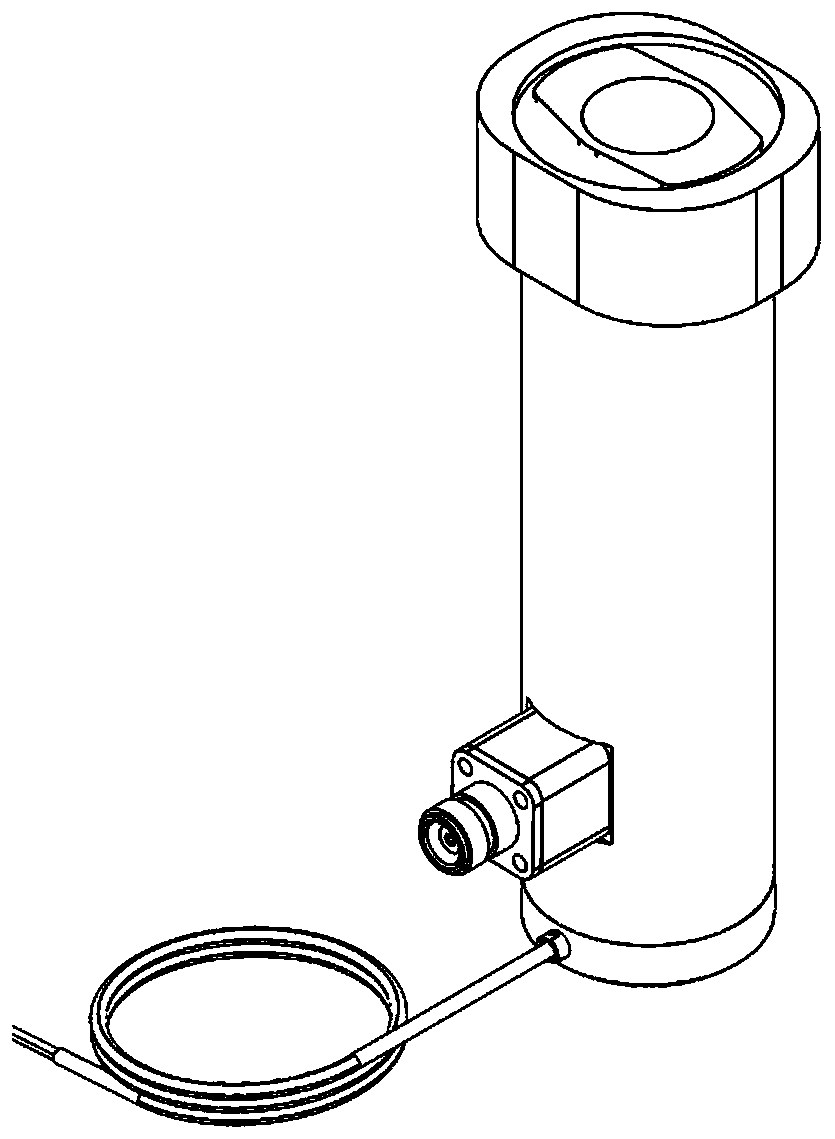

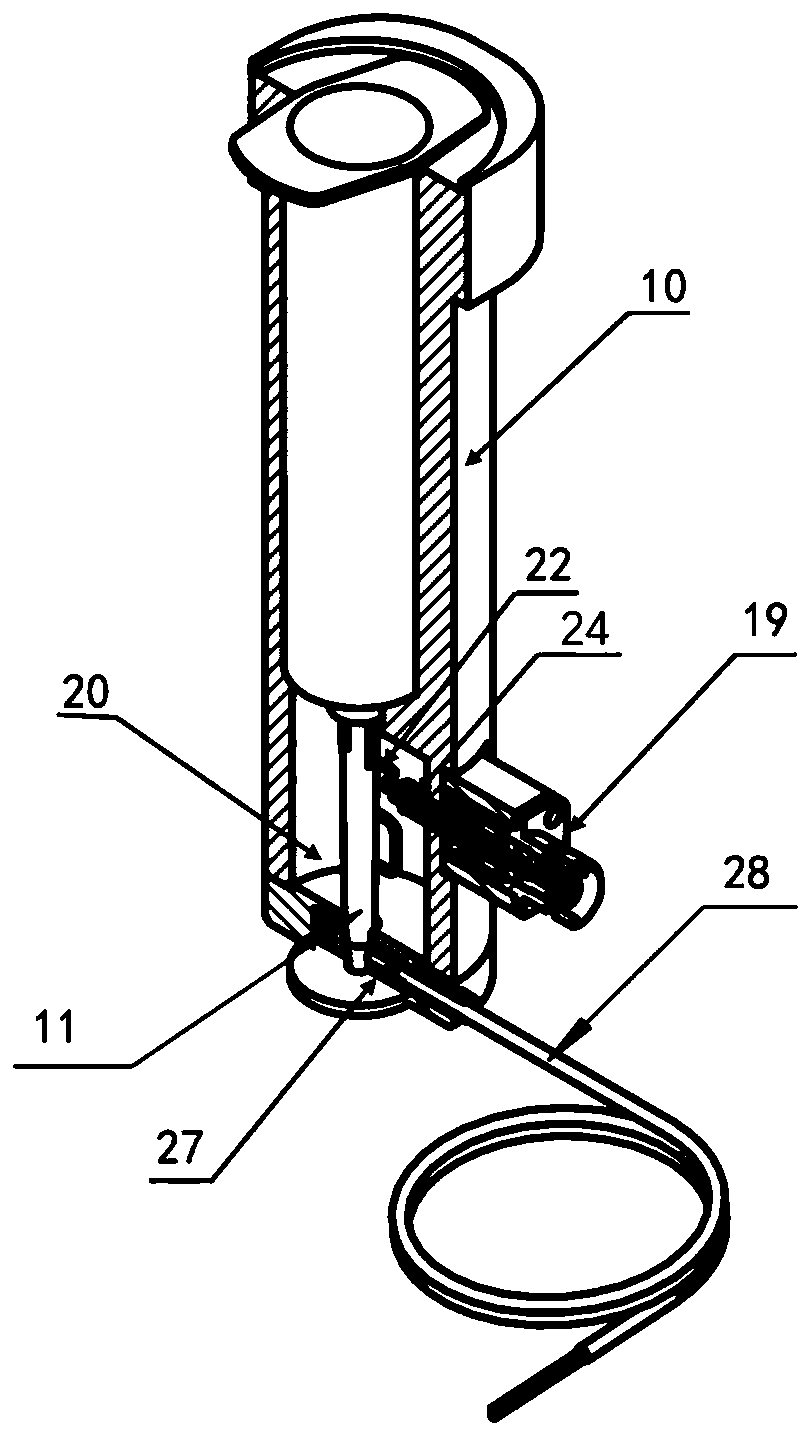

[0056] This embodiment provides a food microwave 3D printing equipment, such as Figure 1 to Figure 3 As shown, the food microwave 3D printing equipment includes: a focused microwave heating unit and a material extrusion unit; the focused microwave heating unit includes a microwave heating cavity 20 and a microwave heating antenna 21, wherein the microwave heating antenna 21 is a bipolar antenna , including an anode antenna 22 and a cathode antenna 23, which are arranged inside the microwave heating cavity 20.

[0057] The material extruding unit includes a barrel 10 and an extrusion nozzle 11; the extrusion nozzle 11 is arranged between the anode antenna 22 and the cathode antenna 23, and the anode antenna 22 and the cathode antenna 23 limit the microwave electric field to the anode antenna 22 and the cathode antenna 23. The position between the cathode antennas 23 realizes focused heating of the extruded material and achieves the effect of instant curing of the extruded mate...

Embodiment 2

[0077] This embodiment provides a food microwave 3D printing system, such as Figure 12 and Figure 13 As shown, the food microwave 3D printing system has image processing functions integrating scanning imaging, image processing, and slice processing. The food microwave 3D printing system includes: a scanning imaging unit, a control unit, a focused microwave heating unit, a 3D printing unit and an anti-leakage unit.

[0078] The food microwave 3D printing system obtains the image information of the target object by scanning the imaging unit, and sends it to the control unit. The control unit slices the image of the target object through cura, and sends corresponding instructions to the 3D printing unit to complete the printing of the shape of the target object. At the same time, the corresponding microwave power is set through the control unit to make the focused microwave heating unit complete the heating treatment.

[0079] The various components of the food microwave 3D p...

Embodiment 3

[0091] This embodiment provides a food microwave 3D printing method, which is applied to the food microwave 3D printing system described in the second embodiment above. The methods include:

[0092] Open the switch button 37 of the cabinet, and add an appropriate amount of food slurry in the barrel 10.

[0093] The target object is placed on the storage table 2 of the three-dimensional scanner 1, and the target object is scanned, and the generated image information is transmitted to the image signal converter 5 through the signal transmission line 4, and the image signal converter 5 automatically converts the image file into an stl format file .

[0094] If there is no target object, the image file of the target object can be directly imported into the image signal converter 5 through the USB interface, and the image signal converter 5 will automatically convert the target file into the stl format.

[0095] According to the appropriate printing parameters, use the built-in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com