High-entropy alloy powder for additive remanufacturing and preparation method thereof

A high-entropy alloy and remanufacturing technology, applied in the field of high-entropy alloy additive remanufacturing, can solve the problems of uneven structure, low solid solubility and high cost, and achieve uniform structure and composition, high microhardness, and powder yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

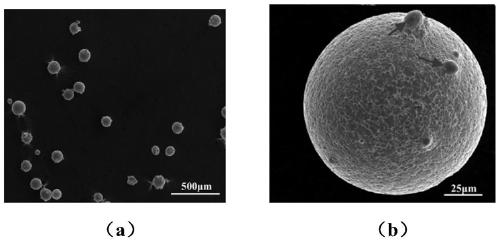

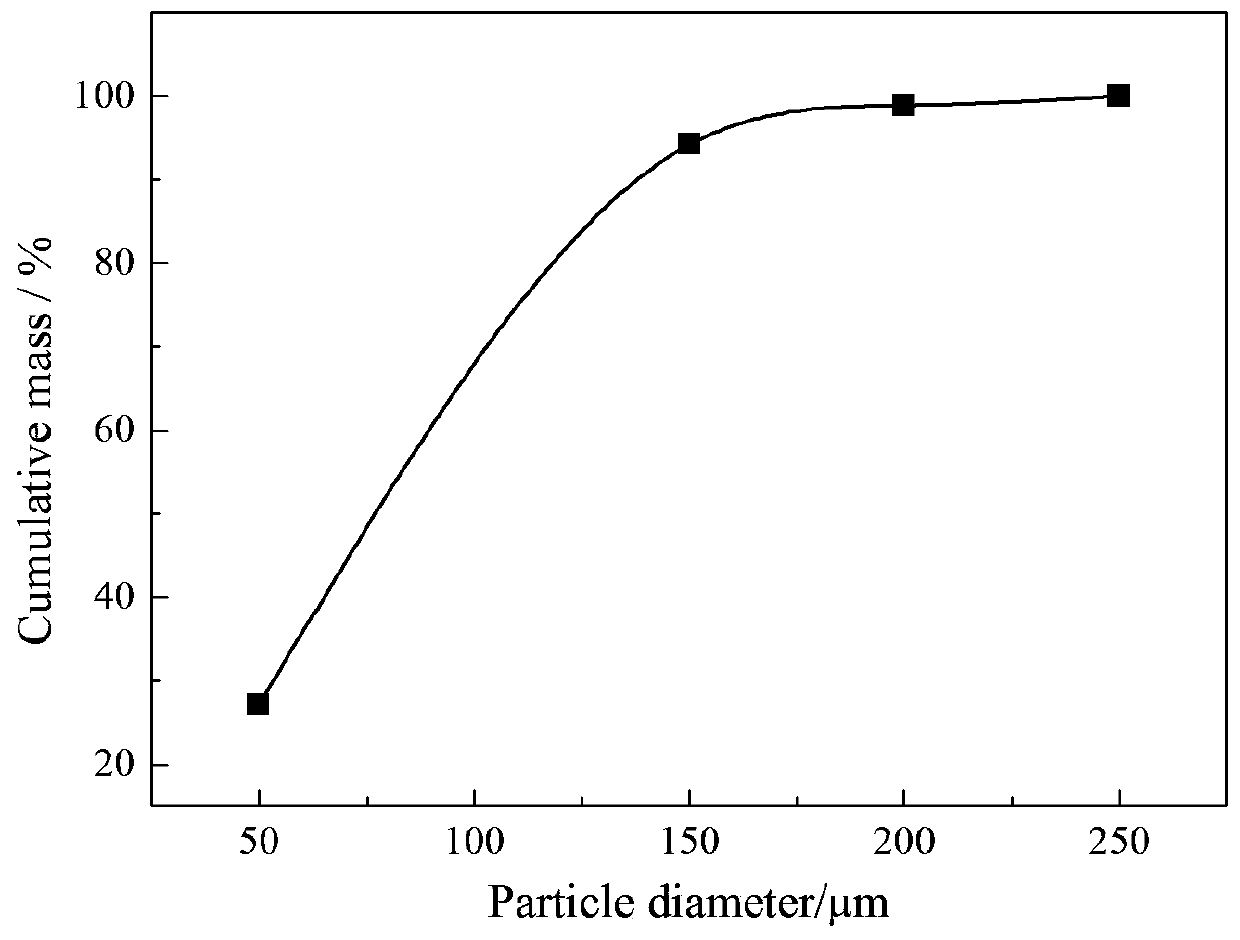

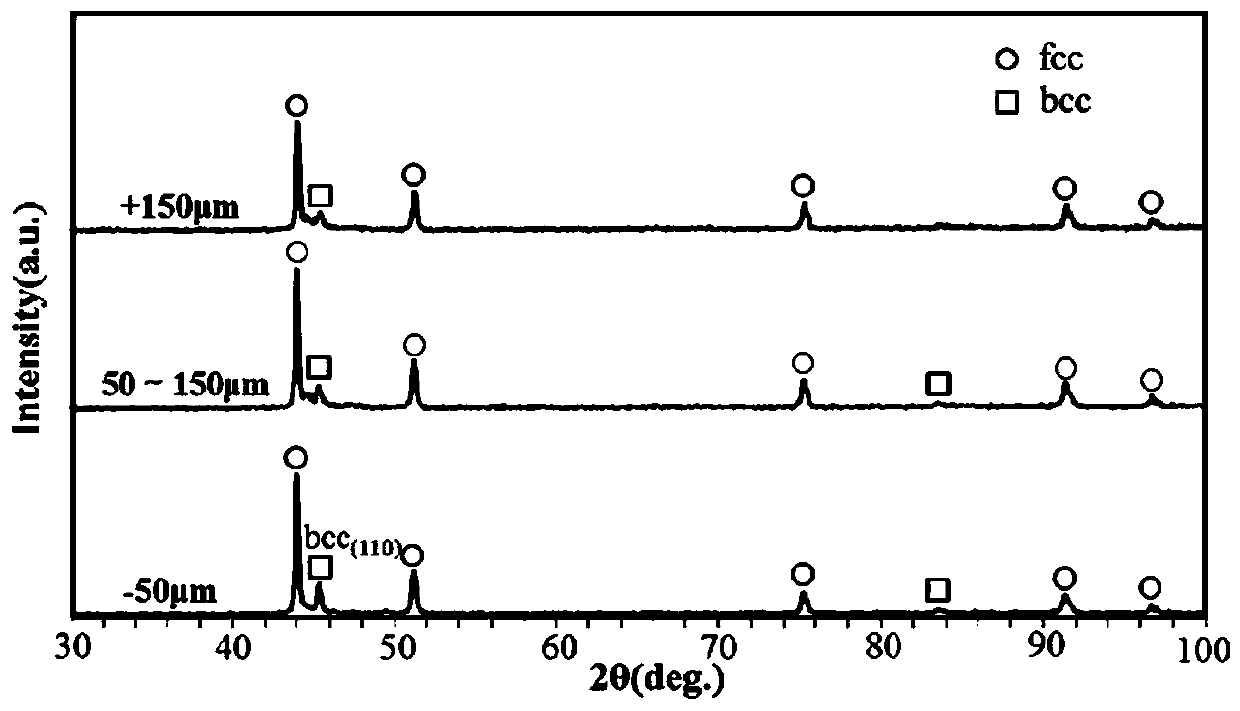

Image

Examples

Embodiment 1)

[0031] The preparation method of the high-entropy alloy powder for additive remanufacturing in this embodiment has the following steps:

[0032] ① Use a grinder to remove impurities and oxide films on the original metal surface of Al, Co, Cu, Ni, and Si bulk materials (purity ≥ 99.9%), and then use the atomic percentage of Al 0.4 CoCu 0.6 NiSi 0.2 Batching, total weight is 20kg.

[0033] ②Put the metal block materials in step ① into the vacuum induction melting furnace in order of melting point from low to high, and vacuumize to vacuum degree -3 MPa, then filled with argon to a pressure of 5×10 -2 Pa, under the protection of argon, the alloy is heated and melted by an induction coil to start smelting. The smelting time is 30 minutes. Electromagnetic stirring is introduced during the smelting process to ensure the uniformity of the alloy composition.

[0034] ③Introduce nitrogen gas through the tightly coupled annular slot nozzle of the atomization equipment to a pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com