Additive for preparing porous pyramid structure by secondary texturing of monocrystalline silicon wafer and application thereof

A technology of pyramid structure and single crystal silicon wafer, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high cost and complex process, achieve surface tension reduction, simple process, and improve microstructure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

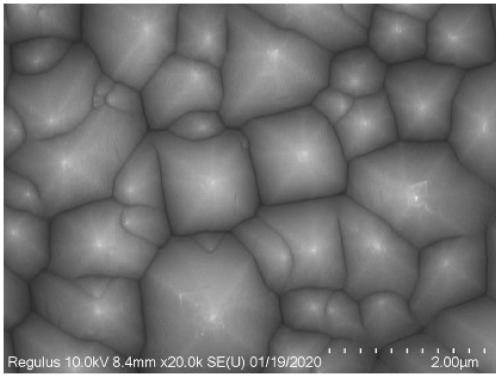

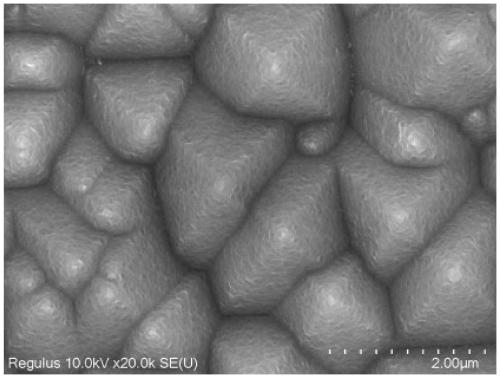

[0025] Such as figure 1 with figure 2 As shown, the present invention provides a kind of method that monocrystalline silicon chip prepares porous pyramid structure, first monocrystalline silicon chip is carried out one-time texturing, makes the monocrystalline silicon chip surface form pyramid structure; The monocrystalline silicon wafer after texturing is subjected to secondary texturing to form a porous pyramid structure on the surface of the monocrystalline silicon wafer;

[0026] The concrete steps of described secondary texturing include:

[0027] 1) Preparation of additives: 0.1% to 10% of sodium polystyrene sulfonate, 2% to 20% of polyethylene gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com