Hydrogel-containing catalyst slurry, catalyst layer prepared from same and fuel cell electrode

A fuel cell electrode and catalyst slurry technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of not being able to meet the requirements of electrodes and difficult to meet high-temperature and low-humidity operating conditions, so as to improve water management problems, improve battery characteristics, The effect of guaranteed output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

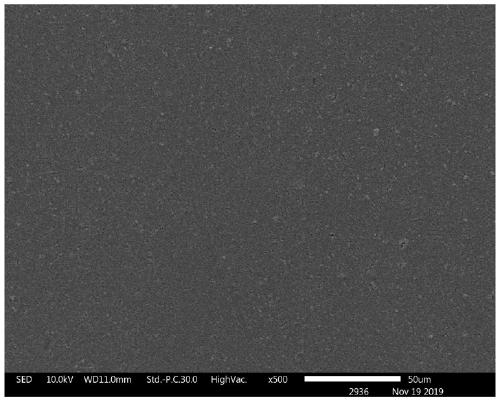

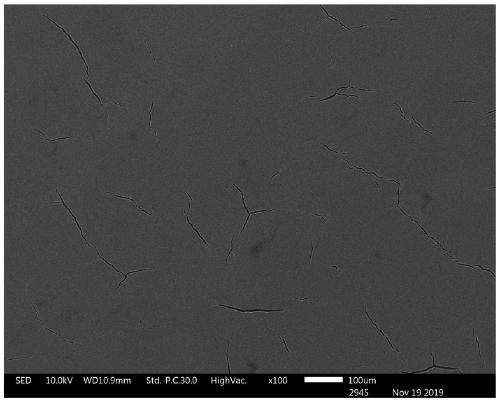

[0032] A fuel cell electrode is prepared through a catalyst slurry containing nano hydrogel, and the steps of the preparation method are as follows:

[0033] Weigh 80mg of Pt / C catalyst (Pt content is 50wt.%), use 3.2g of n-propanol solution as organic solvent, and use ultrasonic dispersion treatment for 30min; then add 100mg Nafion D2020 (20wt.%) and 16mg lignin successively Sodium sulfonate hydrogel (purchased from Shandong West Asia Chemical Industry Co., Ltd.), adopts mechanical stirring and ultrasonic wave to process simultaneously, and the rotating speed of mechanical stirring is 100 and 1500r / min, and the power of ultrasonic dispersion is 800W, and wherein first carries out ultrasonic treatment time for 0.5h, mechanical treatment for 1.5h, and then ultrasonic treatment for 0.5h, until it is fully and uniformly dispersed to obtain a catalyst slurry, wherein the solid content in the catalyst slurry is 3.4%, and this solid content refers to the Pt / C catalyst, Content of io...

Embodiment 2

[0037] A fuel cell electrode is prepared through a catalyst slurry containing nano hydrogel, and the steps of the preparation method are as follows:

[0038] Weigh 30mg of PtNi / C catalyst (Pt content is 50wt.%), use 0.3g of isopropanol solution as organic solvent, adopt ultrasonic dispersion treatment for 45min; then add 52.5mg SS700C (20wt.%) and 1.5mg sodium lignosulfonate hydrogel (purchased from Shandong West Asia Chemical Industry Co., Ltd.), adopt mechanical stirring and ultrasonic treatment simultaneously, the rotating speed of mechanical stirring is 500 and 3000r / min, the ultrasonic dispersion The power is 300W, and the processing time is 30min each. After it is fully and uniformly dispersed, a catalyst slurry is prepared, wherein the solid content in the catalyst slurry is 10.9%. The solid content refers to the Pt / C catalyst, ion conductor and nanohydraulic Glue content. Among them, the Pt loading amount of the Pt / C catalyst in this example, the mass ratio of the hy...

Embodiment 3

[0041] A fuel cell electrode is prepared through a catalyst slurry containing nano hydrogel, and the steps of the preparation method are as follows:

[0042] Weigh 146mg of PtCo / C catalyst (Pt content is 41wt.%), use 7.317g of isopropanol solution as organic solvent, use ultrasonic dispersion treatment for 45min; then add 1.036g Nafion D520 (5wt.%) and 22mg of acrylic acid Hydrogel-like (purchased from Shanghai Yuanye Biotechnology Co., Ltd.), using ultrasonic treatment, the power of ultrasonic dispersion is 500W, and the treatment time is 60min. After it is fully and uniformly dispersed, a catalyst slurry is obtained, wherein the catalyst slurry The solid content is 2.6%, which refers to the content of Pt / C catalyst, ion conductor and nano hydrogel. Among them, the Pt loading amount of the Pt / C catalyst in this example, the mass ratio of the hydrogel to the catalyst in the catalyst slurry, and the solid content in the catalyst slurry are all shown in Table 1.

[0043] Get tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com