Papaya yoghourt and preparation method thereof

A technology for yogurt and papaya, applied in the field of food processing, can solve the problems of not meeting market demand and not proposing specific solutions, and achieve the effects of promoting stability, easy control, and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of papaya yoghurt, said papaya yoghurt uses yoghurt containing lactic acid bacteria as a starter, after fermenting in a fermentation tank for a certain period of time, it is obtained after ultrasonic assistance; said papaya yoghurt includes the following raw materials in parts by weight: papaya sauce 3- 20 parts, 20-50 parts of fresh milk, 1-10 parts of starter, 10-15 parts of sweetener, 1-5 parts of stabilizer; wherein, the stabilizer is pectin, carrageenan and transglutaminase Mixing; and in this embodiment, the conditions for the ultrasonic auxiliary action are: power 120-250W, frequency 25-35KHz, and action time 6-10min;

[0035] Wherein, the lactic acid bacteria are composed of Streptococcus thermophilus and Lactobacillus bulgaricus, the weight ratio of Streptococcus thermophilus and the Lactobacillus bulgaricus is 1-3:1; the sweetener is honey, white granulated sugar, fructose One or more in , sucrose and maltose; The mass ratio in the mixing of described p...

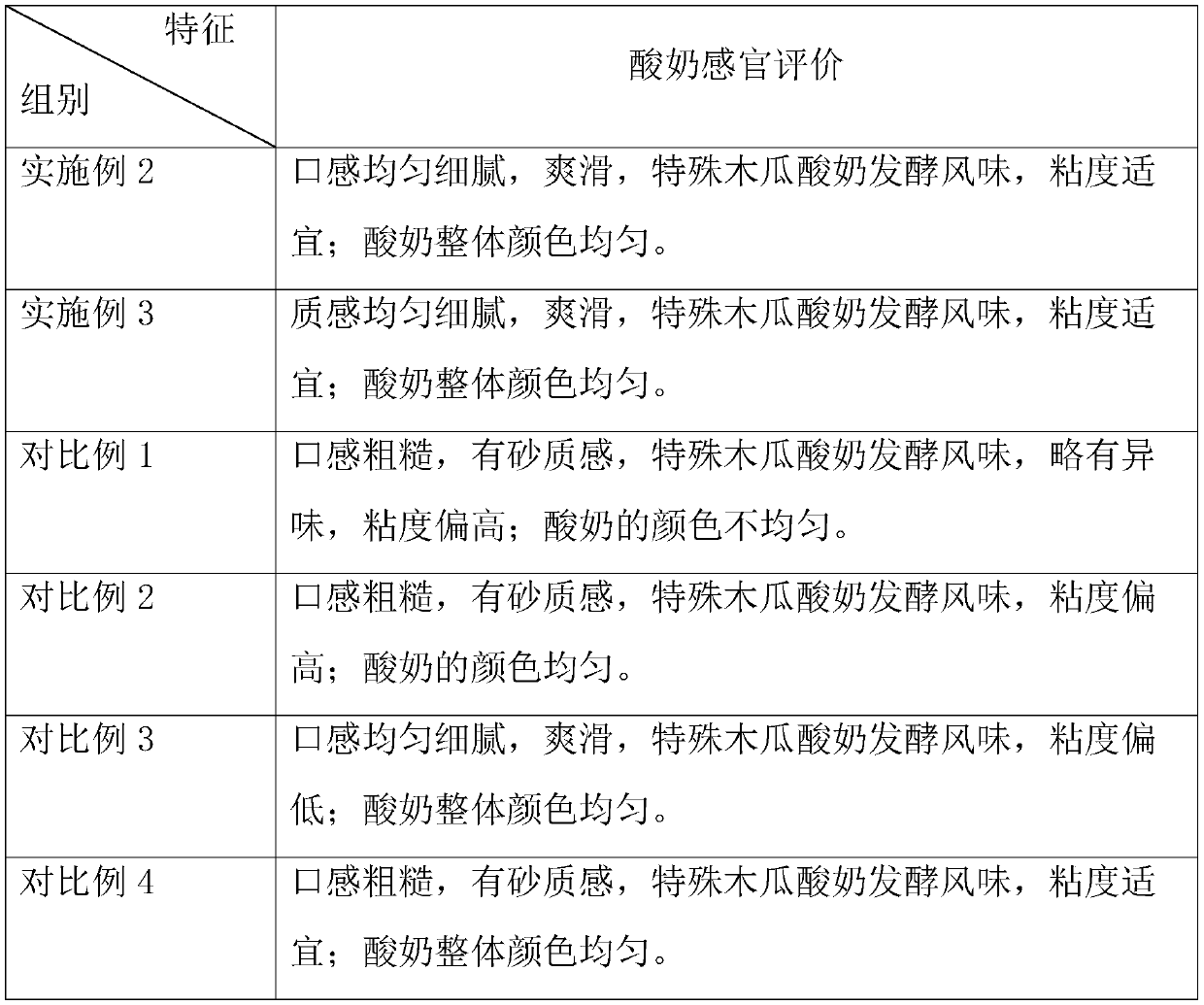

Embodiment 2

[0045] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further preference based on them.

[0046] This embodiment provides a kind of papaya yoghurt, said papaya yoghurt uses yoghurt containing lactic acid bacteria as a starter, after fermenting in a fermentation tank for a certain period of time, it is obtained after ultrasonic assistance; said papaya yoghurt includes the following raw materials in parts by weight: 3 parts of papaya sauce, 50 parts of fresh milk, 10 parts of starter, 10 parts of sweetener, 1 part of stabilizer; wherein, the stabilizer is a mixture of pectin, carrageenan and transglutaminase; and in this implementation In an example, the conditions for the ultrasonic auxiliary action are: power 120W, frequency 25KHz, and action time 6-10min;

[0047] Wherein, in this embodiment, the lactic acid bacteria are composed of Streptococcus thermophilus and Lactobacillus bulgaricus, the weight ratio...

Embodiment 3

[0057] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further preference based on them.

[0058] This embodiment provides a kind of papaya yoghurt, said papaya yoghurt uses yoghurt containing lactic acid bacteria as a starter, after fermenting in a fermentation tank for a certain period of time, it is obtained after ultrasonic assistance; said papaya yoghurt includes the following raw materials in parts by weight: 20 parts of papaya sauce, 50 parts of fresh milk, 10 parts of starter, 15 parts of sweetener, 5 parts of stabilizer; Wherein, described stabilizer is the mixing of pectin, carrageenan and transglutaminase; And in this implementation In an example, the conditions for the ultrasonic auxiliary action are: the power is 120W, the frequency is 35KHz, and the action time is 6-10min;

[0059] Wherein, in the present embodiment, the lactic acid bacteria are composed of Streptococcus thermophilus and Lac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com