Gas recovery/concentration device

A gas and recovery method technology, which is applied in the field of temperature swing adsorption carbon dioxide recovery and concentration devices, can solve the problems of high gas pressure loss, difficult to enlarge, and cannot ignore the operating cost, and achieves the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

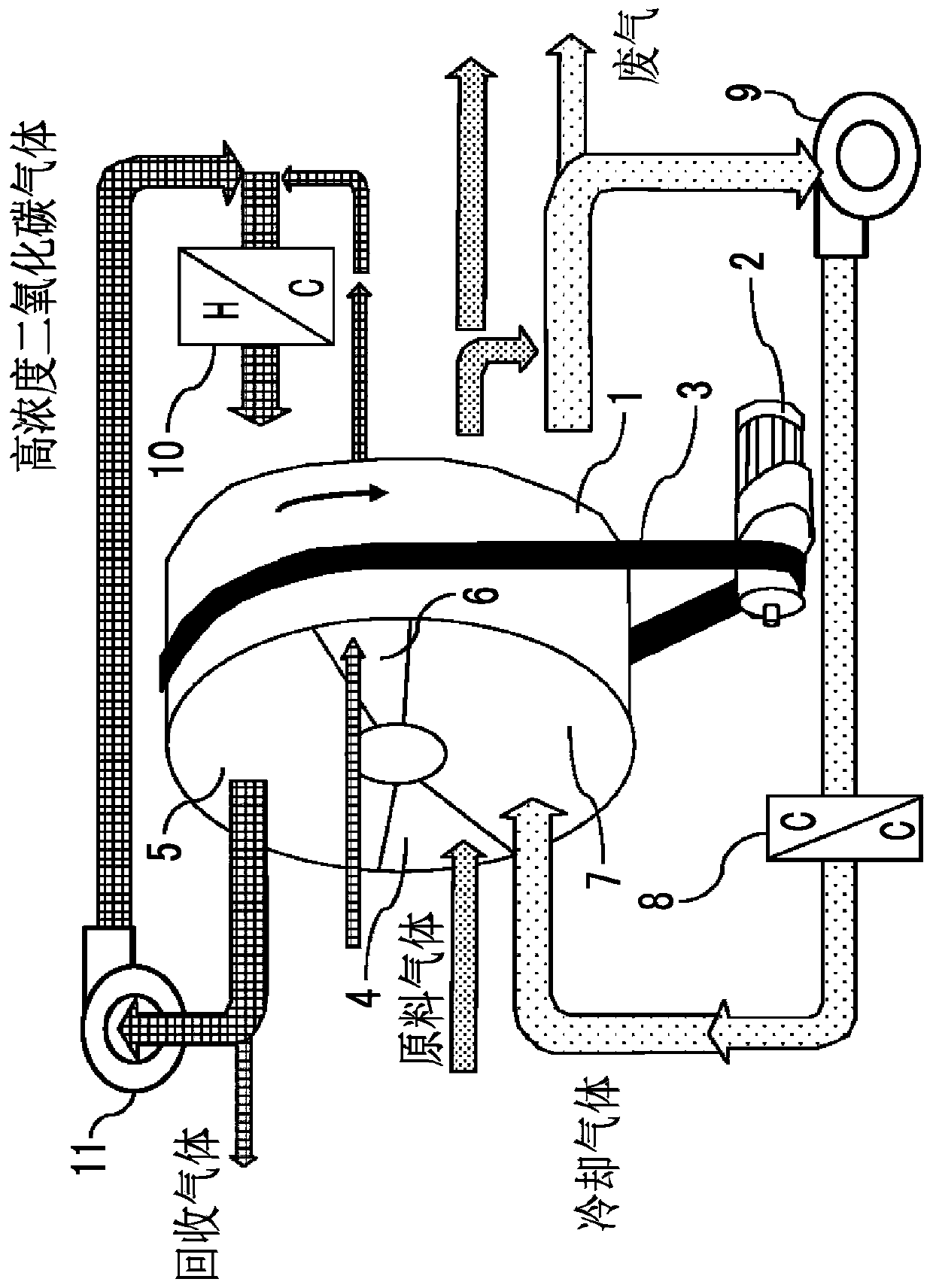

[0096] Image 6 The horizontal type of Example 1 is shown in. Regarding the honeycomb rotor 12, the following sheet material was corrugated to a pitch of 3.0 mm and a height of 2.0 mm, and it was wound into a rotor to obtain a volume specific gravity of 150 kg / m containing 50% by weight of solid amine particles 3 The honeycomb rotor 12, the sheet is 30-40g / m with inorganic fibers such as glass fiber as the main body 2 The porous paper is coated with a coating solution containing solid amine particles with a particle size distribution of 0.02 to 0.1 mm and a heat-resistant and water-resistant binder and dried.

[0097] The carbon dioxide recovery and concentration device equipped with the rotor 12 is provided with an adsorption zone 13 and a desorption zone 14. The honeycomb rotor 12 is configured to return from the adsorption zone 13 to the adsorption zone 13 through the desorption zone 14.

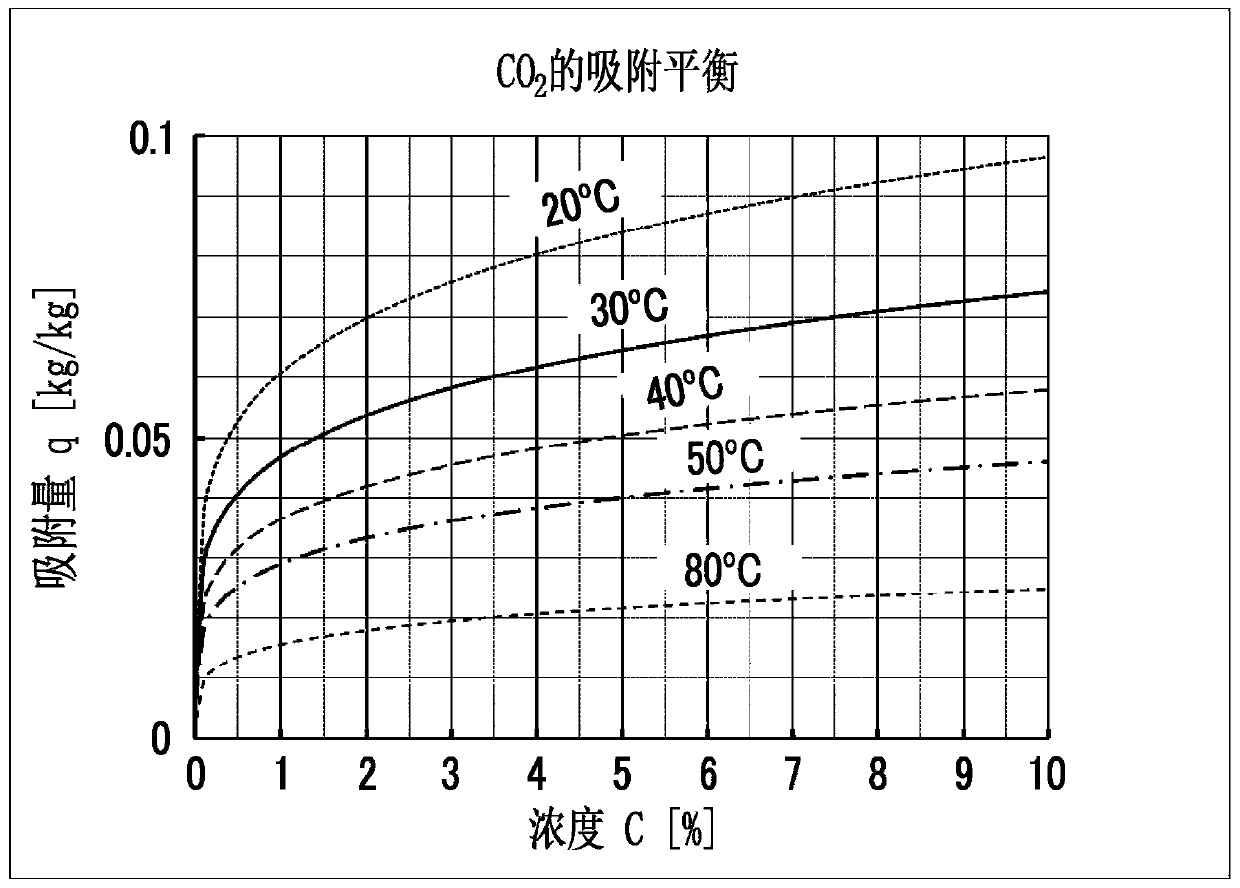

[0098] If the raw material gas after denitrification, desulfurization, dust removal, and co...

Embodiment 2

[0103] Figure 7 The vertical embodiment 2 is shown in. The honeycomb absorbing carbon dioxide moves to the desorption zone 14 through the rotation of the rotor. In the desorption zone, a circulation loop connecting the inlet and the outlet is formed, and a blower and a heat exchanger are installed in the loop, and a temperature-regulating heater as a gas heater is installed in the back section. The waste heat such as exhaust gas and hot water passes through the high temperature side of the heat exchanger.

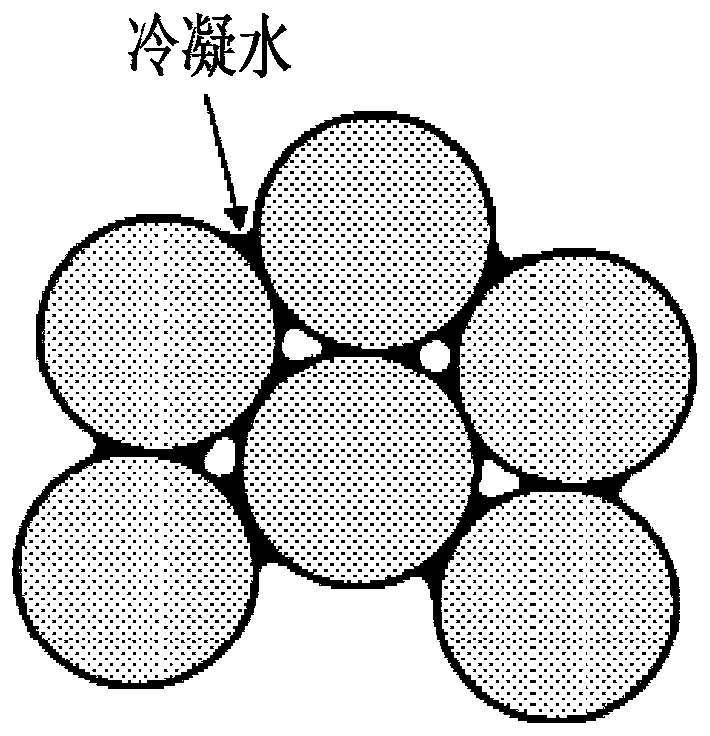

[0104] The gas containing carbon dioxide as the main component in the low-temperature circulation circuit is circulated by a blower, and water is supplied to the low-temperature side of the heat exchanger using a sprayer, and the water film generated on the heat transfer surface is heated and evaporated to become saturated vapor containing gas. In addition, heating is performed by a temperature-regulating heater in the subsequent stage, and the relative humidity is slightly ...

Embodiment 3

[0106] Figure 8 Example 3 is shown in. The flue gas is processed for denitrification, desulfurization, and dust removal to obtain the raw material gas, but the gas is kept at a temperature close to 100°C and the dew point temperature. It has a structure in which the source gas side desorbs and regenerates the high temperature side of the saturated steam generating heat exchanger, and then cools and dehumidifies the high temperature side of the cooling and dehumidification heat exchanger, and exhausts gas by adsorbing the rotor with carbon dioxide.

[0107] The low temperature side of the heat exchanger for generating desorption and regeneration saturated steam constitutes a circulation loop of the inlet and outlet of the carbon dioxide adsorption rotor regeneration and desorption side and the blower. The gas with carbon dioxide as the main component in the circuit is circulated through a blower. If water is supplied to the low temperature side heat exchanger, the water film form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com