Method of connecting porous structure and substrate

A connection method and porosity technology, used in medical science, prostheses, bone implants, etc., can solve the problems of weakness, reduced base structure strength, and low proportion of stents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

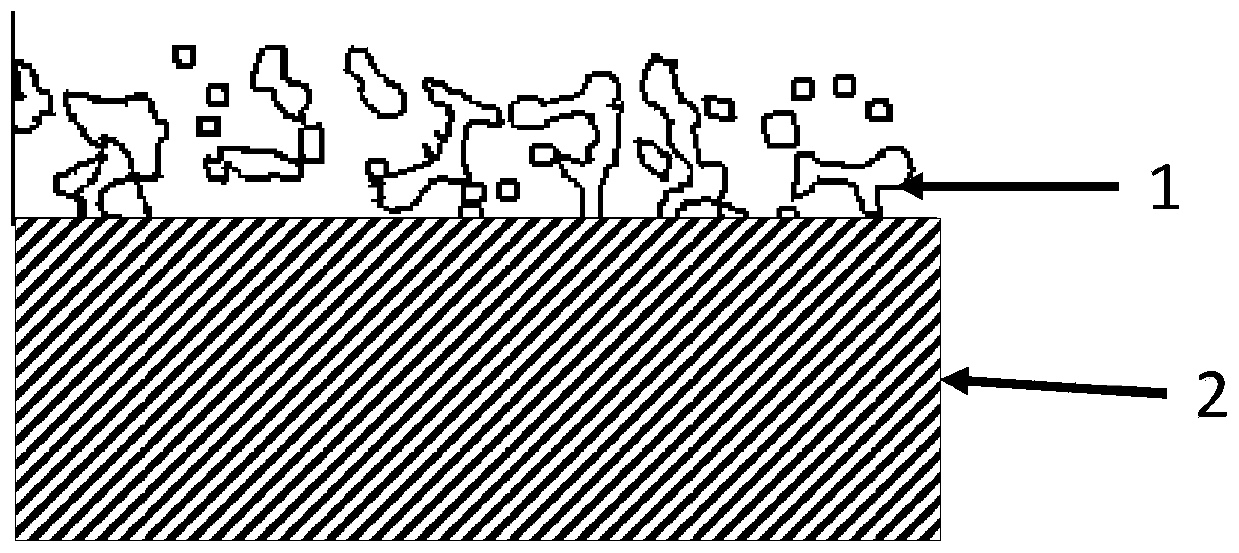

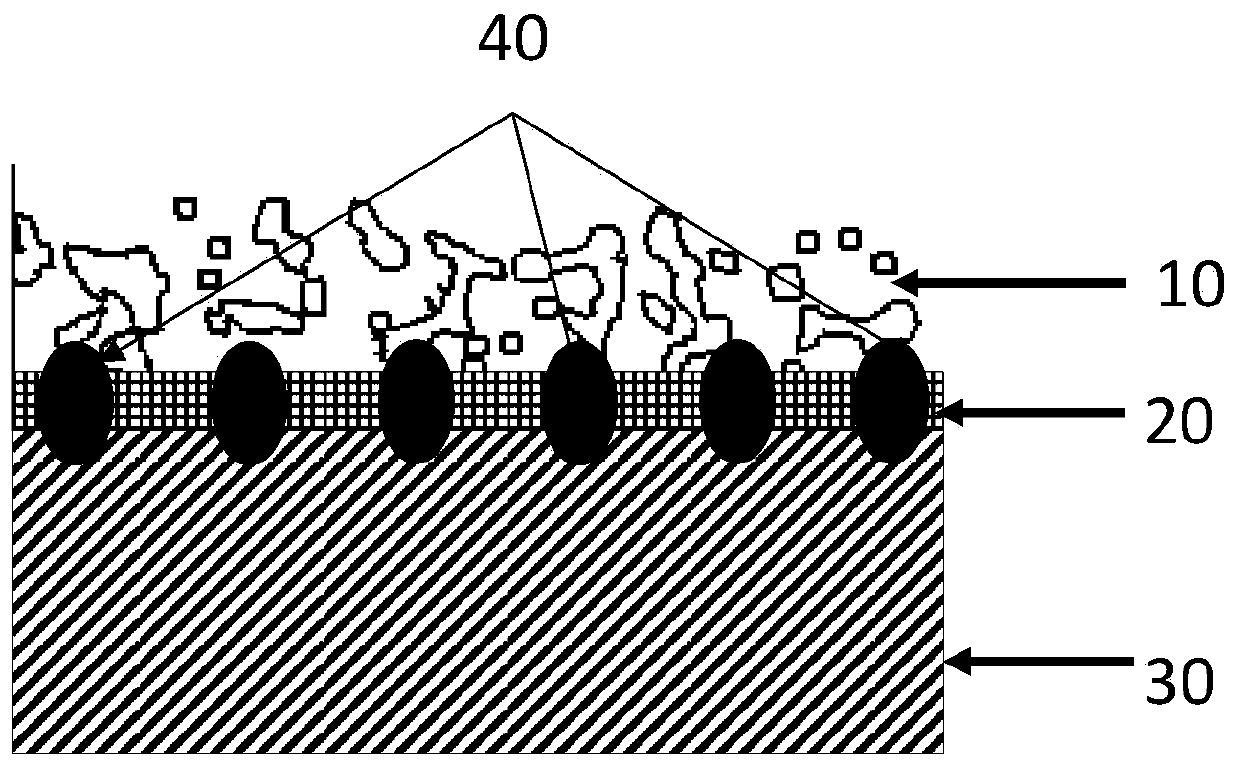

[0142] The present invention relates to a connection structure, such as figure 2 As shown, it includes a substrate 30 , an intermediate body 20 , and a porous surface structure 10 . Wherein, the porous surface structure 10 and the intermediate body 20 form a composite body, and the composite body is connected to the substrate 30 through the connection between the intermediate body 20 and the substrate 30 .

[0143] The preferred substrate 30 is solid, which facilitates the overall strength of the joint structure. The exemplary base 30 is made of metal material, formed by various methods such as forging, casting, powder metallurgy or metal powder injection molding, and various machining processes can be performed on it. The intermediate body 20 and the substrate 30 are preferably effectively combined by welding (such as laser welding), figure 2 The symbol 40 in represents the welding point 40 between the two, and the position of the welding point 40 can be freely selected a...

Embodiment 2

[0155] For the above-mentioned first embodiment, the intermediate body generally includes the bottom (or includes the bottom and the periphery at the same time), and the bottom is roughly in the shape of a thin sheet or a thin plate; the shape and size of an intermediate body (or a combination of multiple intermediate bodies) can be compared with those on the substrate. The shape and size of the connection area of the intermediate body are basically the same; the connection area of the intermediate body and the substrate is welded, so that the porous surface structure forming a complex with the intermediate body covers the connection area of the substrate and constitutes the surface at the connection area.

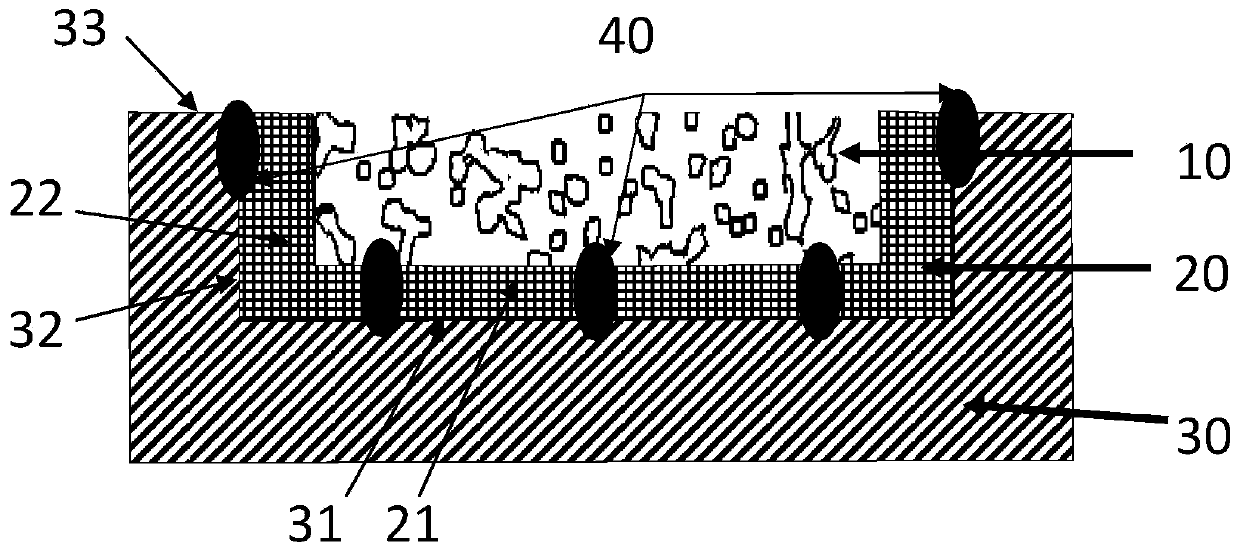

[0156] The main difference from Embodiment 1 is that in the connection structure between the porous surface structure and the substrate described in Embodiment 2, the intermediate between the porous surface structure and the substrate uses an anchor point form, and the...

Embodiment 3

[0163] For the above-mentioned embodiment two, several intermediates in the form of anchor points are independent of each other and form a complex with the porous surface structure; the shape and size of a complex (or after a plurality of complexes are combined) can be connected with the substrate The shape and size of the regions are basically the same; the independent anchor point structure is welded to the corresponding points of the connection region of the substrate, so that the complex covers the connection region of the substrate and forms the surface of the connection region (mainly with a porous surface structure).

[0164] The main difference from Example 2 is that in the connection structure between the porous surface structure and the substrate described in Example 3, the intermediate between the porous surface structure and the substrate uses a joint anchor point structure, that is, it contains multiple Anchor points, and each anchor point is connected to at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com