Sewage treatment device system and method thereof

A sewage treatment and sewage technology, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc. It can solve the problems of limited autotrophic nitrification, excessive total nitrogen in effluent, and nutrient competition. , to achieve the effect of convenient industrial application, easy operation, and avoidance of total nitrogen exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

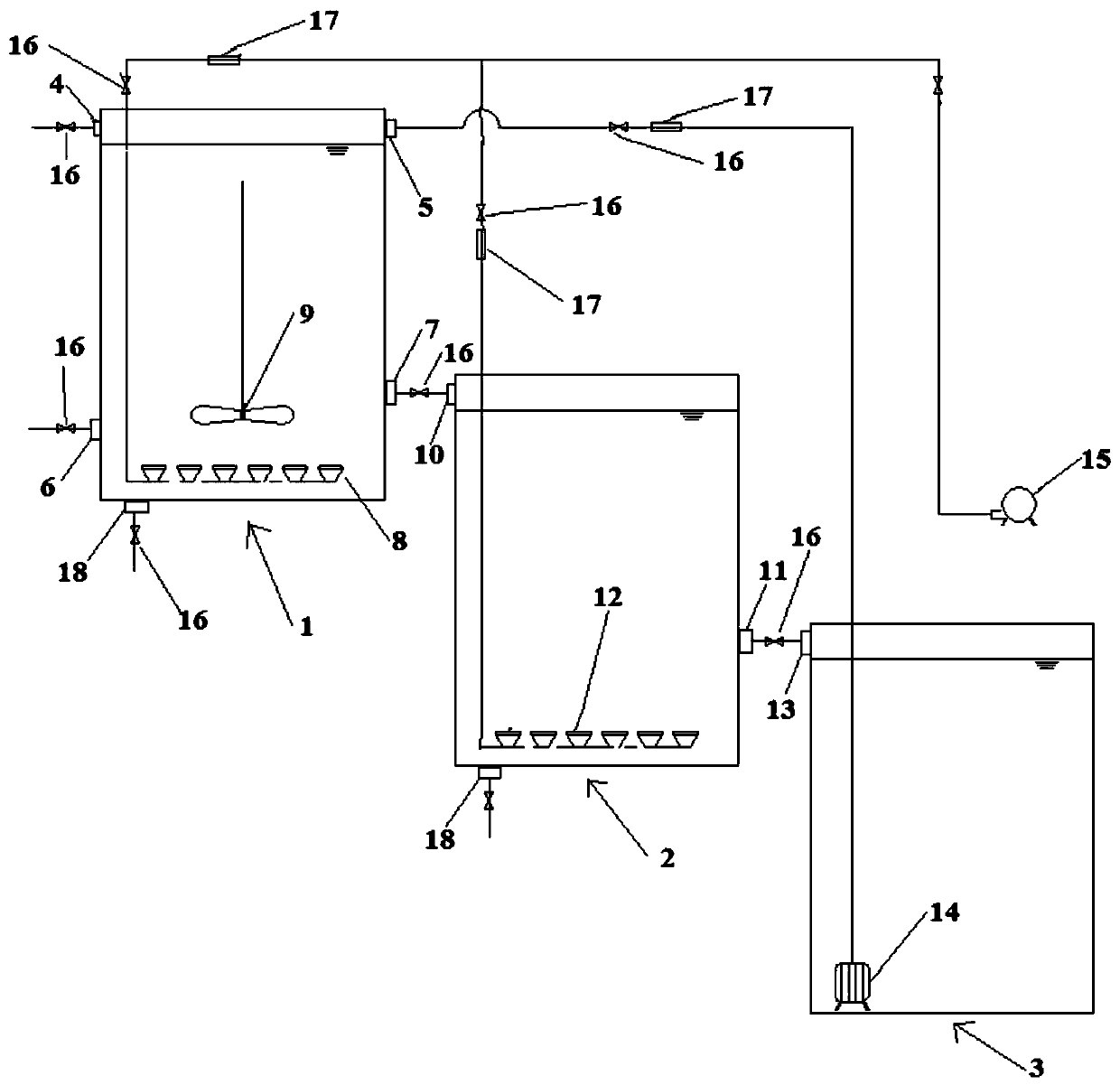

[0069] This embodiment provides a device system for sewage treatment, such as figure 1 As shown, it includes a first reaction tank 1, a second reaction tank 2 and a reclaimed water storage tank 3;

[0070] The first reaction tank 1 is provided with a first water inlet 4, a second water inlet 5, a first water outlet 6, and a second water outlet 7; the first aerator 8, Stirrer 9;

[0071] The second reaction tank 2 is provided with a third water inlet 10 and a third water outlet 11; the second reaction tank 2 is provided with a second aerator 12;

[0072] The reclaimed water storage tank 3 is provided with a fourth water inlet 13; the reclaimed water storage tank 3 is provided with a submersible pump 14;

[0073] The second water outlet 7 is connected to the third water inlet 10 through a pipe body provided with a valve 16, and the third water outlet 11 is connected to the fourth water inlet 13 through a pipe body provided with a valve 16, The submersible pump 14 is connected...

Embodiment 2

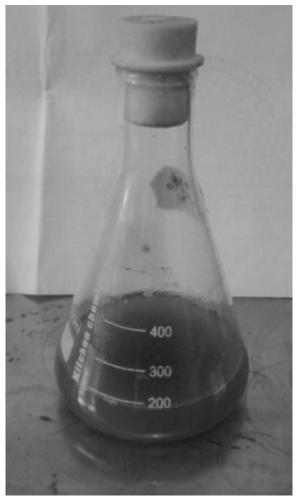

[0079] Take the activated sludge with stable denitrification effect from urban sewage treatment plants and inoculate it in the simulated SBR reactor, so that the MLSS is 3500mg / L. Use aerobic denitrification medium for culture, turn on the aerator, control the DO to 6mg / L, and the temperature at 25°C. Operation cycle: water inflow for 30 minutes, aeration for 4 hours, standing for 1 hour, and 70% water outlet. Run 20 cycles according to the above cycle to obtain activated sludge containing aerobic denitrifying bacteria with stable aerobic denitrification effect, such as figure 2 It was shown that the aerobic denitrifying bacteria group can remove nitrate nitrogen at a rate of more than 20 mg / L·h under the condition of sufficient carbon source.

[0080] Aerobic denitrification medium: sodium acetate 4g / L, potassium nitrate 0.35g / L, compound potassium salt (potassium dihydrogen phosphate: dipotassium hydrogen phosphate=1:1) 0.2g / L, magnesium sulfate heptahydrate 0.1g / L L, tra...

Embodiment 3

[0082] Take the activated sludge with stable denitrification effect from urban sewage treatment plants and inoculate it in the simulated SBR reactor so that the MLSS is 5000mg / L. The autotrophic nitrification medium was used for culture, the aerator was turned on, the DO was controlled at 4 mg / L, and the temperature was 25°C. Operation cycle: water inflow for 30 minutes, aeration for 6 hours, standing for 1 hour, and 70% water discharge. Run 30 cycles according to the above cycle to obtain the nitrifying bacteria activated sludge with stable autotrophic nitrification effect, such as image 3 It was shown that the ammonia nitrogen removal rate of the autotrophic nitrifying bacteria group can reach more than 8 mg / L·h under aerobic conditions.

[0083] Autotrophic nitrification medium: ammonium sulfate 0.4g / L, sodium bicarbonate 1.0g / L, compound potassium salt (potassium dihydrogen phosphate: dipotassium hydrogen phosphate=1:1) 0.15g / L, magnesium sulfate heptahydrate 0.1g / L, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com