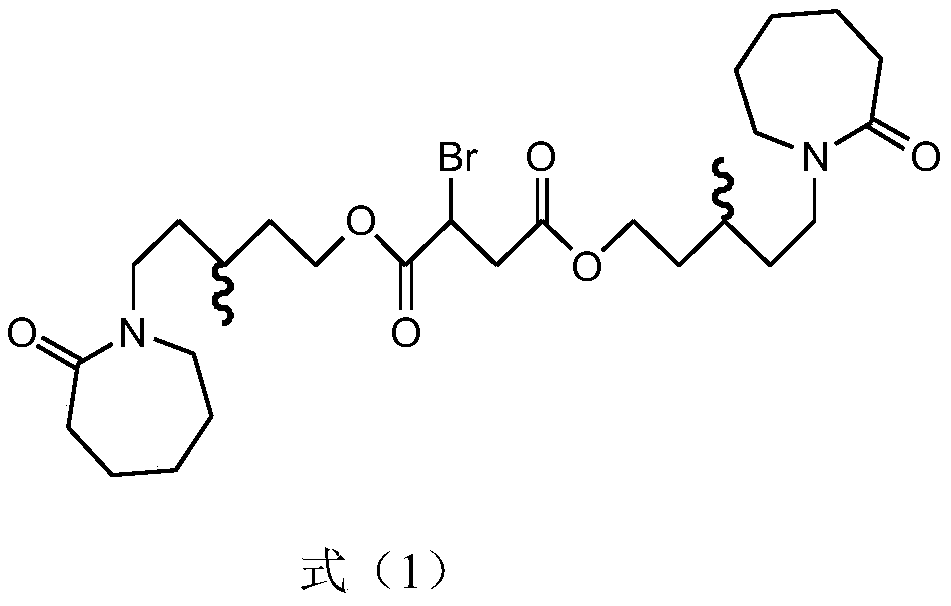

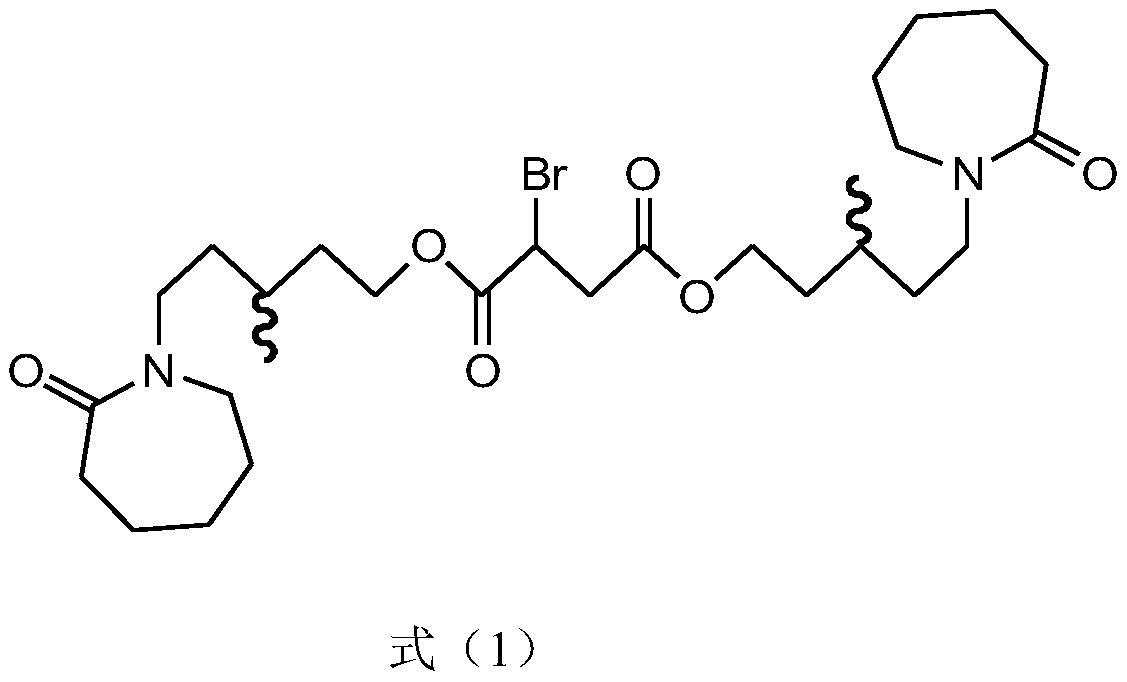

Hyperbranched amide hydrate kinetic inhibitor as well as preparation method and application thereof

A kinetic inhibitor, hydrate technology, applied in chemical instruments and methods, drilling compositions, mechanical equipment, etc., can solve problems such as limited practical use scenarios, achieve a wide range of use and conditions, and high yield , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

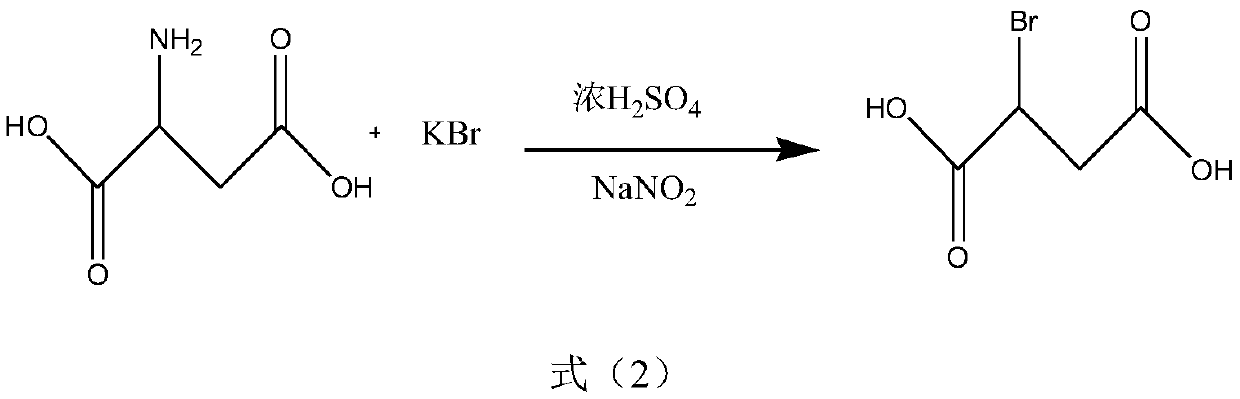

[0031] A preparation method for a hyperbranched amide hydrate kinetic inhibitor, specifically comprising the following steps:

[0032] (1) Take 10.156g of aspartic acid and 42.1g of KBr into a three-necked flask, then connect the three ports of the flask with a thermometer, a condenser tube, and a rubber hole plug, and the upper end of the condenser tube is connected to the gas path. After evacuating, pass nitrogen gas to initially remove the air in the pipeline. Slowly add 25.8mL of concentrated sulfuric acid into 200mL of distilled water under ice bath conditions, transfer to the flask after cooling. 9.57gNaNO 2 Add 20mL of distilled water, add drop by drop from the rubber stopper hole to the flask with a syringe at low temperature, seal it, stop the reaction after 2h, extract the product with ethyl acetate, and then use anhydrous MgSO 4 Drying is carried out to obtain 2-bromosuccinic acid;

[0033](2) Under a nitrogen atmosphere, add 10.64g of 2-bromosuccinic acid, 30g o...

Embodiment 2

[0037] Same as Example 1, the difference is:

[0038] In step (1), aspartic acid and KBr mass ratio are 1:3, and the total mass of aspartic acid and KBr and NaNO 2 The mass ratio of NaNO is 4:1; 2 The mass ratio of distilled water to distilled water is 1:20, the mass ratio of distilled water to concentrated sulfuric acid is 10:1, and the reaction time is 3 hours.

[0039] In step (2), the mass ratio of 2-bromosuccinic acid and propynyl alcohol is 1:2, the mass ratio of the total mass of 2-bromosuccinic acid and propynyl alcohol and p-toluenesulfonic acid is 50:1 , the mass ratio of p-toluenesulfonic acid and benzene is 1:100, the reaction temperature is 80 ℃, and the reaction time is 48 hours; the volume ratio of ethyl acetate and the NaOH solution of 10wt% in the mixed solution is 4:1, The first rotary evaporation temperature is 40°C, and the second rotary evaporation temperature is 35°C.

[0040] In step (3), 2-bromopropynyl succinate and vinyl caprolactam mass ratio are ...

Embodiment 3

[0042] Same as Example 1, the difference is:

[0043] In step (1), aspartic acid and KBr mass ratio are 1:5, and the total mass of aspartic acid and KBr and NaNO 2 The mass ratio of NaNO is 5:1; 2 The mass ratio of distilled water to distilled water is 1:40, the mass ratio of distilled water to concentrated sulfuric acid is 30:1, and the reaction time is 4 hours.

[0044] In step (2), the mass ratio of 2-bromosuccinic acid and propynyl alcohol is 1:4, the mass ratio of the total mass of 2-bromosuccinic acid and propynyl alcohol and p-toluenesulfonic acid is 70:1 , the mass ratio of p-toluenesulfonic acid and benzene is 1:150, the reaction temperature is 90 DEG C, and the reaction time is 36 hours; the volume ratio of ethyl acetate and the mass fraction of 10wt% NaOH solution in the mixed solution is 5:1, The first rotary evaporation temperature is 55°C, and the second rotary evaporation temperature is 45°C.

[0045] In step (3), the mass ratio of propynyl 2-bromosuccinate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com