Demethylated lignin, preparation method thereof and application of the demethylated lignin in phenolic resin adhesive

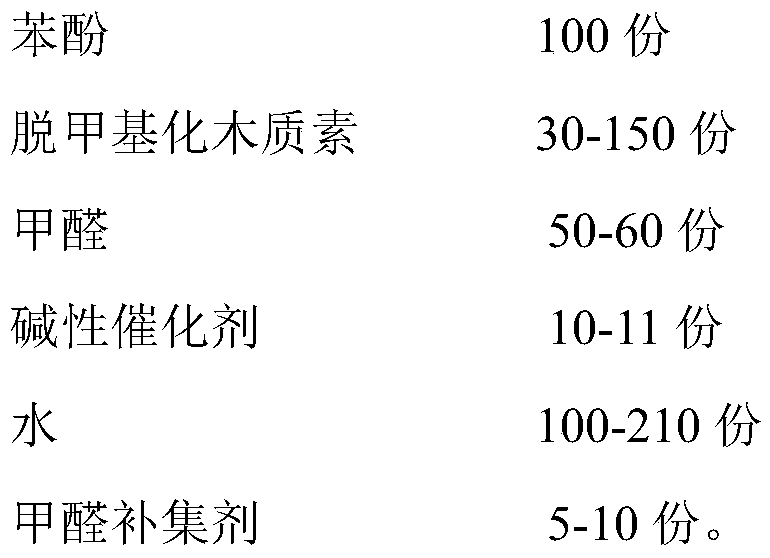

A phenolic resin glue and demethylation technology, applied in the field of materials, can solve the problem of high process requirements, achieve the effects of reducing the gel time, avoiding the use of reaction conditions and environmentally unfriendly reagents, and reducing the amount of formaldehyde released

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

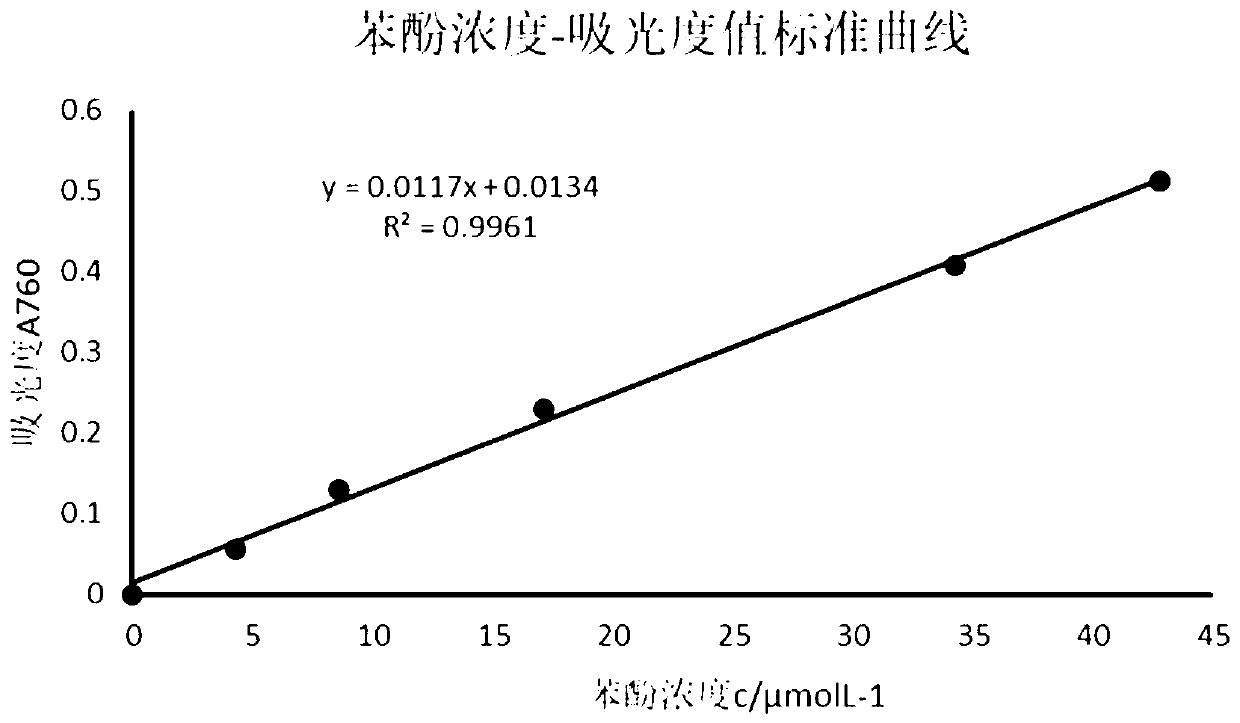

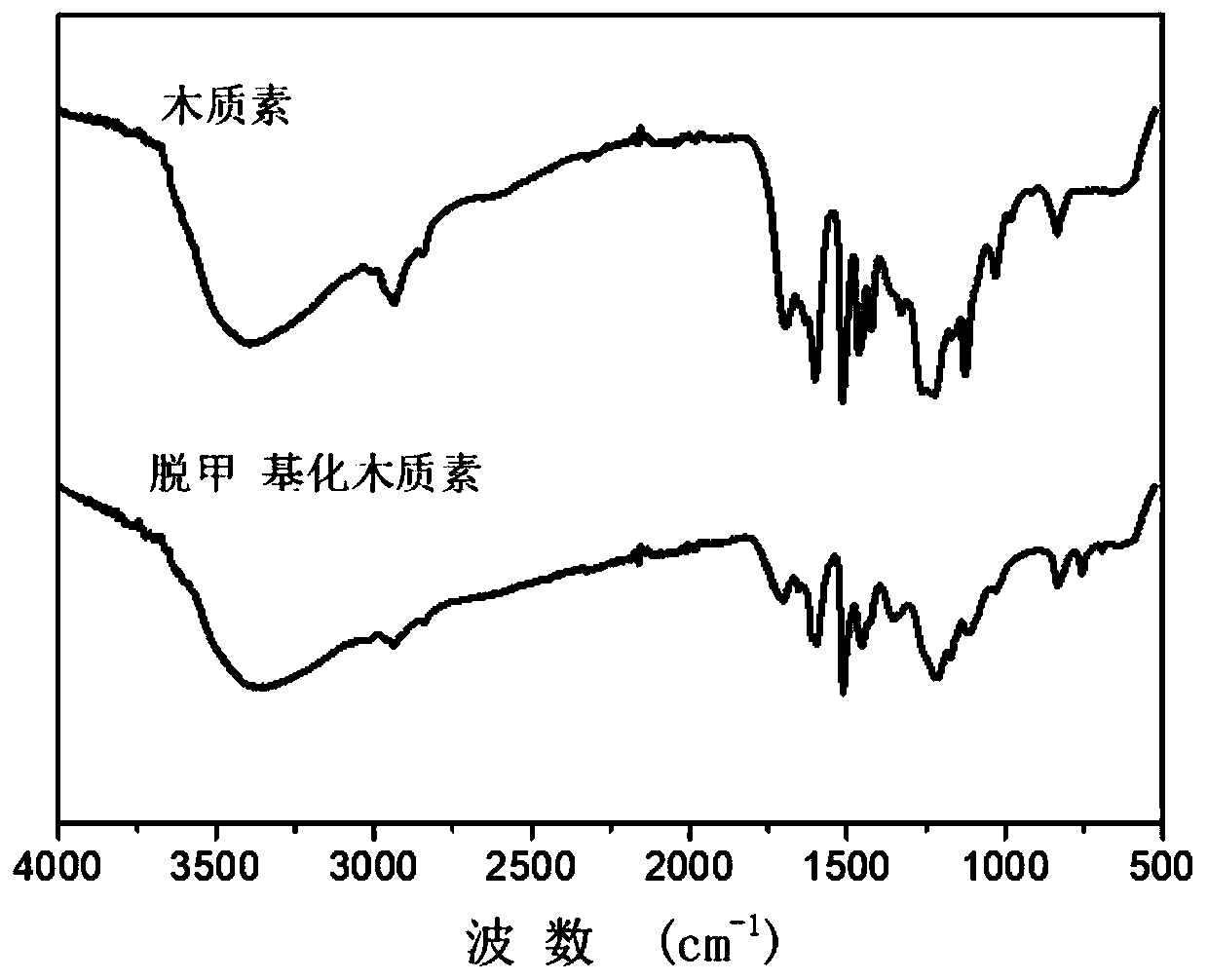

[0058] Dissolve 0.5g of alkali lignin in 50mL of Britton-Robinson buffer solution with a pH of 4.0, raise the temperature to 30°C, add 0.002g / L 2,2'-azino-bis-(3-ethylbenzothiapyrroline- 6-sulfonic acid) and 5U fungal laccase (the laccase is derived from Coriolus versicolor), sealed for 12 hours to obtain demethylated lignin. Filter the reaction solution, wash it with water until neutral, dry it in a vacuum oven at 80°C to constant weight, and obtain demethylated lignin after drying, weigh the product, the yield is 80%, and the phenolic hydroxyl content of unmodified alkali lignin The phenolic hydroxyl content of demethylated lignin was 4.42%, and the phenolic hydroxyl content increased by 1.76%.

Embodiment 2

[0060] Dissolve 0.5g of alkali lignin in 50mL of Britton-Robinson buffer solution with a pH of 4.0, raise the temperature to 30°C, add 5U of fungal laccase (the laccase is derived from Coriolus versicolor), and seal for 12 hours to obtain Kylated lignin. Filter the reaction solution, wash it with water until neutral, dry it in a vacuum oven at 80°C to constant weight, and obtain demethylated lignin after drying, weigh the product, the yield is 80%, and the phenolic hydroxyl content of unmodified alkali lignin The phenolic hydroxyl content of demethylated lignin was 3.90%, and the phenolic hydroxyl content increased by 1.24%.

Embodiment 3

[0062] Dissolve 0.5g alkali lignin in 50mL Britton-Robinson buffer solution with pH 4.0, raise the temperature to 30°C, add 0.002g / L 2,2'-azino-bis-3-ethylbenzothiazoline-6- Sulfonic acid and 5U fungal laccase (the laccase is derived from Coriolus versicolor), reacted for 12 hours under aerobic conditions (by bubbling aeration, under the condition of oxygen flow rate of 10mL / min) to obtain demethylation lignin. Filter the reaction solution, wash it with water until neutral, dry it in a vacuum oven at 80°C to constant weight, and obtain demethylated lignin after drying, weigh the product, the yield is 80%, and the phenolic hydroxyl content of unmodified alkali lignin The phenolic hydroxyl content of demethylated lignin was 4.68%, and the phenolic hydroxyl content increased by 2.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com