Silicon wafer cutting fluid suitable for on-line recovery and supply circulation system and preparation method thereof

A circulation system and cutting fluid technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of large foaming, slow foam elimination, and affecting cutting performance, so as to achieve slow change in conductivity, suppress foam generation, reduce Putrefaction bubbling and spoilage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

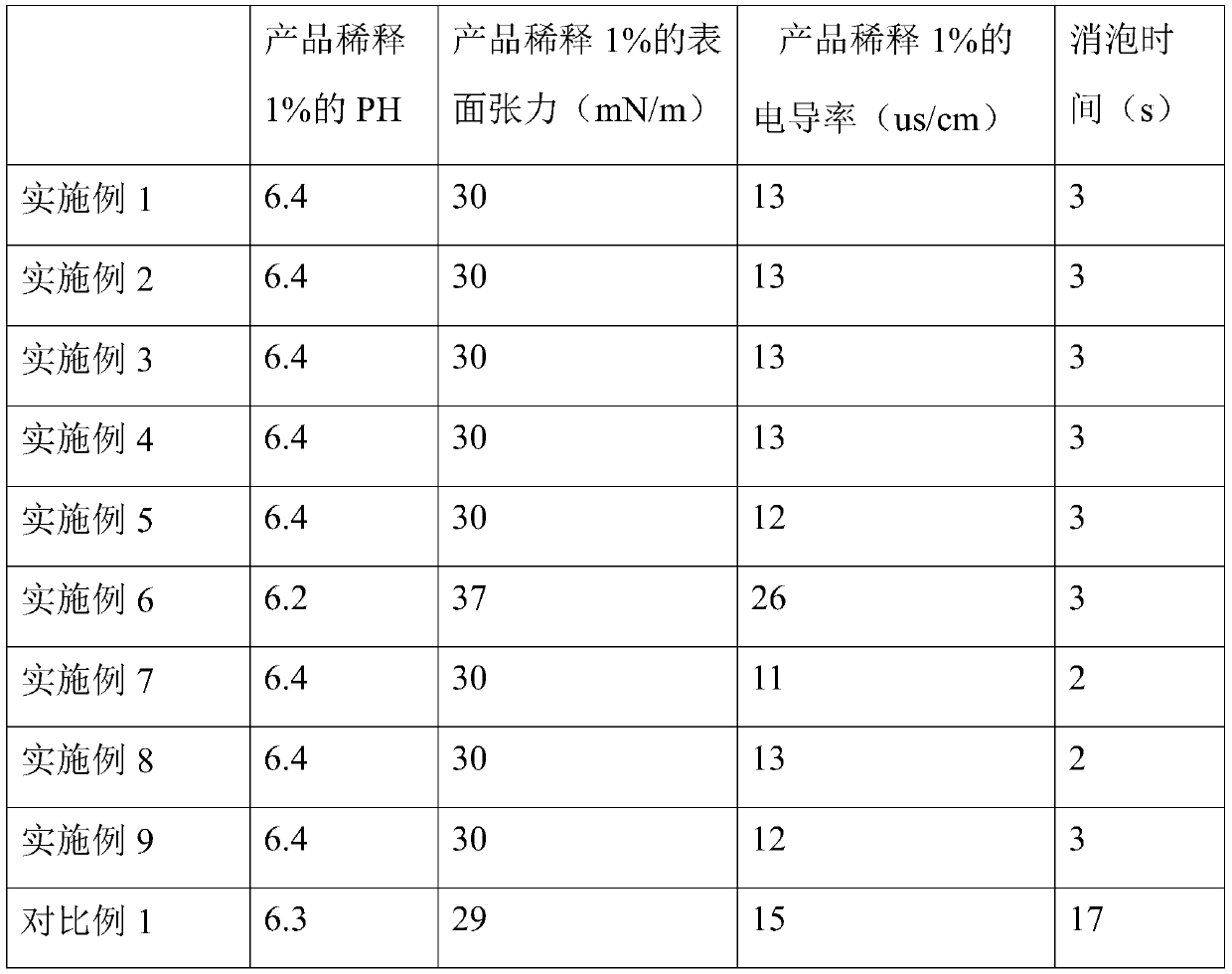

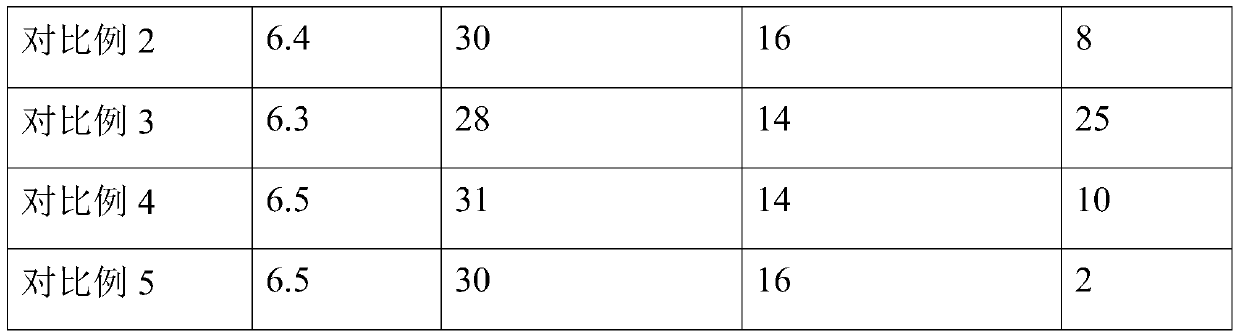

Examples

Embodiment 1

[0023] A silicon chip cutting fluid suitable for on-line recovery and supply circulation system, which includes the following components in weight percentage: 0.1% of triethanolamine borate, 0.1% of foam suppressor, 0.05% of non-foaming emulsifier, bactericidal and bacteriostatic agent 0.1%, polyethylene glycol 5%, non-foaming penetrant 1%, low-foaming cleaning agent 5% and deionized water 88.65%;

[0024] Wherein, the suds suppressor is obtained by mixing acetylenic diol and isooctyl alcohol in a mass ratio of 1:1;

[0025] The non-foaming emulsifier is obtained by mixing isomeric alcohol polyoxyethylene ether 1005 and FT62 at a mass ratio of 1:1;

[0026] The bactericidal and antibacterial agent is obtained by mixing isothiazolinone and s-triazine in a mass ratio of 1:1;

[0027] The non-foaming penetrating agent is obtained by mixing Dow EH-9, Dow TRITON DF-20 and low-foaming fatty alcohol polyoxyalkyl ether PlurafacLF 221 according to the mass ratio of 1:1:1;

[0028] Th...

Embodiment 2

[0031] A silicon chip cutting fluid suitable for on-line recovery and supply circulation system, which includes the following components in weight percentage: 0.1% of triethanolamine borate, 0.1% of foam suppressor, 0.05% of non-foaming emulsifier, bactericidal and bacteriostatic agent 0.1%, polyethylene glycol 5%, non-foaming penetrant 1%, low-foaming cleaning agent 5% and deionized water 88.65%;

[0032] Wherein, the foam suppressor is obtained by mixing acetylenic diol and isooctyl alcohol in a mass ratio of 1:2;

[0033] The non-foaming emulsifier is obtained by mixing isomeric alcohol polyoxyethylene ether 1005 and FT62 at a mass ratio of 1:2;

[0034] The bactericidal and antibacterial agent is obtained by mixing isothiazolinone and s-triazine in a mass ratio of 1:2;

[0035] The non-foaming penetrating agent is obtained by mixing Dow EH-9, Dow TRITON DF-20 and low-foaming fatty alcohol polyoxyalkyl ether PlurafacLF 221 according to the mass ratio of 1:2:2;

[0036] Th...

Embodiment 3

[0039] A silicon chip cutting fluid suitable for on-line recovery and supply circulation system, which includes the following components in weight percentage: 0.1% of triethanolamine borate, 0.1% of foam suppressor, 0.05% of non-foaming emulsifier, bactericidal and bacteriostatic agent 0.1%, polyethylene glycol 5%, non-foaming penetrant 1%, low-foaming cleaning agent 5% and deionized water 88.65%;

[0040] Wherein, the antifoaming agent is isooctyl alcohol;

[0041] The non-foaming emulsifier is FT625;

[0042] The bactericidal and antibacterial agent is s-triazine;

[0043] The non-foaming penetrant is Dow TRITON DF-20;

[0044] The low foam cleaning agent is organic amine ester TPP.

[0045] The silicon chip cutting fluid suitable for on-line recovery and supply circulation system is prepared by the following method: start the reactor, and turn on the temperature control device to control the temperature within 60°C, use the above-mentioned components by weight percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com