Electroless nickel-phosphorus-cobalt plating bath, and electroless nickel-phosphorus-cobalt plating film

A technology of electroless nickel plating and nickel salt, which can be used in liquid chemical plating, coating, printed circuit manufacturing, etc., and can solve problems such as insufficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

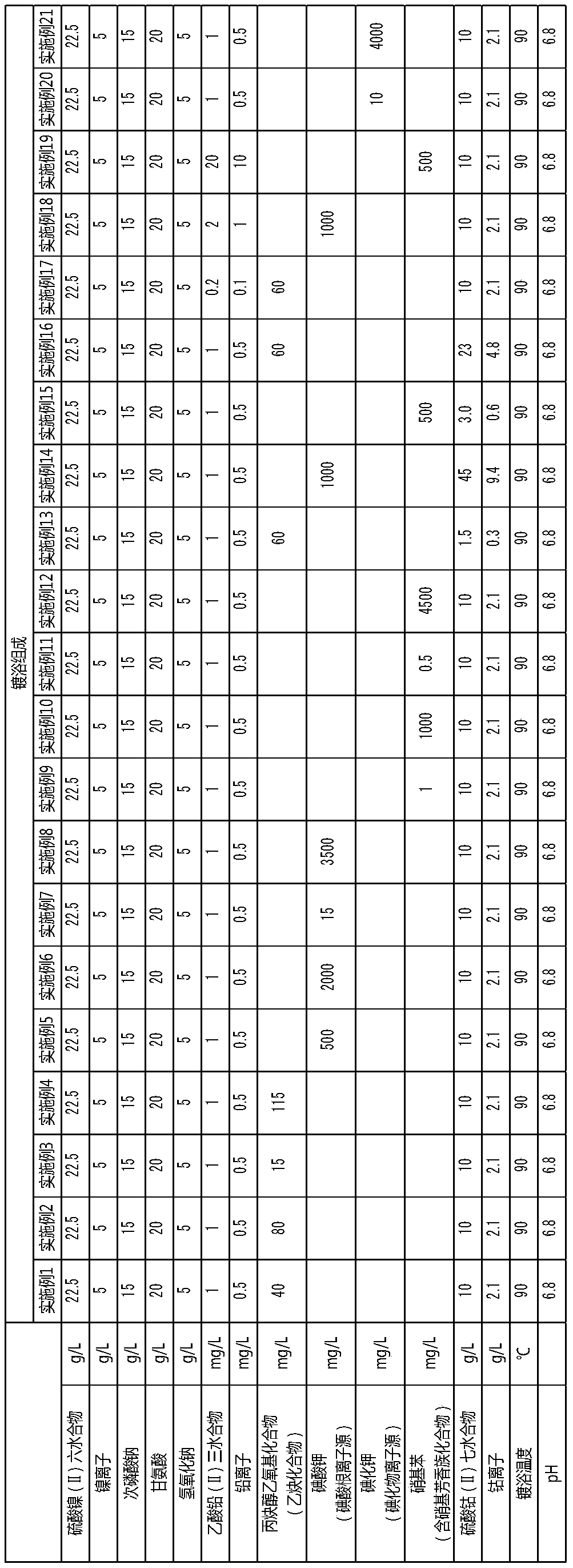

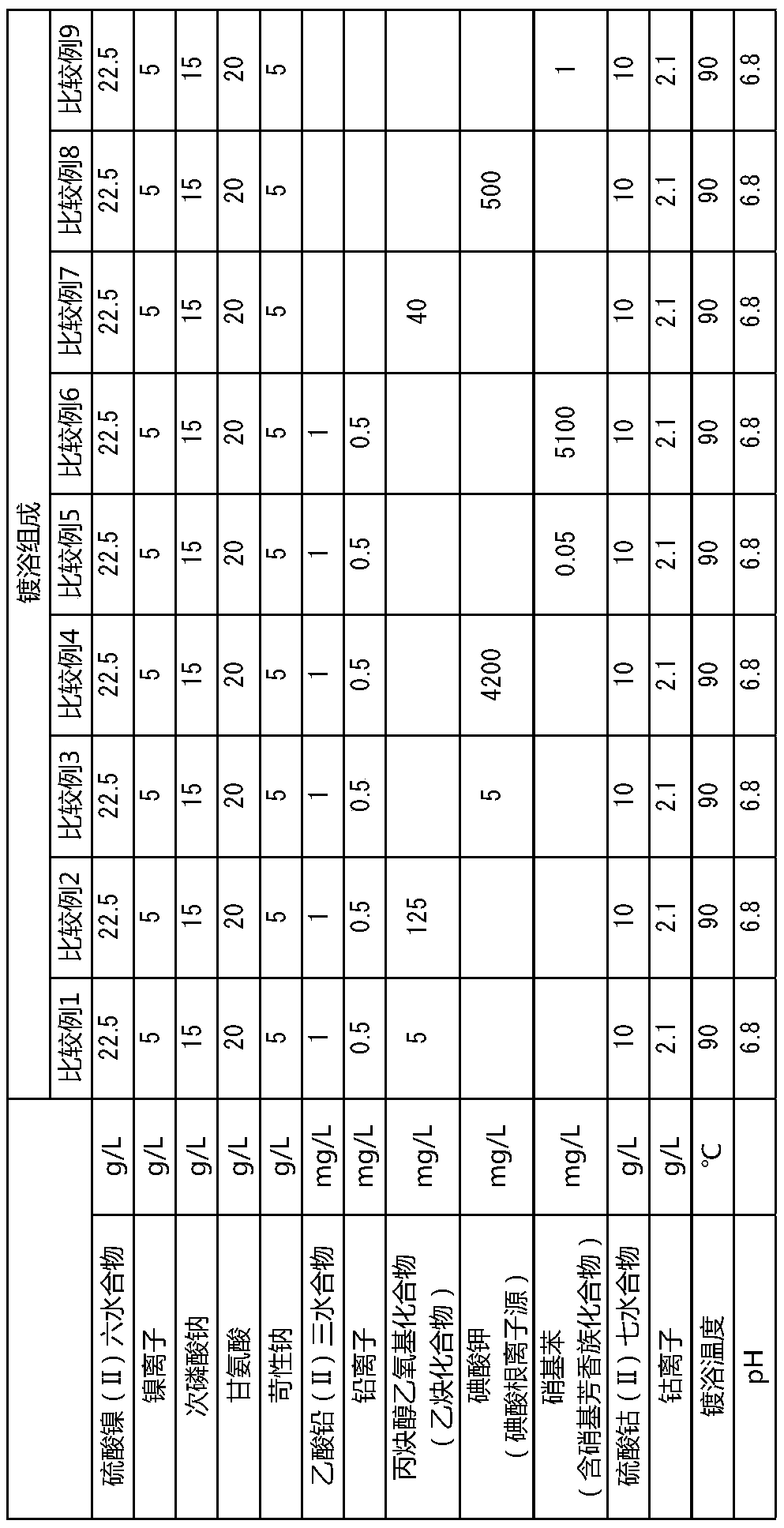

Embodiment 1~21、 comparative example 1~9

[0072] (Preparation of plating bath)

[0073] Nickel(II) sulfate hexahydrate as a water-soluble nickel salt; sodium hypophosphite as a reducing agent; lead(II) acetate trihydrate as a heavy metal compound; cobalt(II) sulfate heptahydrate as a cobalt-containing compound ; propynyl alcohol ethoxylate, potassium iodate or nitrobenzene as an oxidizing agent; glycine as a complexing agent; By stirring, the plating baths of Examples 1-21 and Comparative Examples 1-9 were prepared. In addition, the temperature of the plating bath was set to 90 degreeC, and pH was set to 6.8.

[0074] (plating treatment)

[0075] Next, the SPCC-SB plate (size: 50mm×50mm, thickness: 4mm) as the object to be plated was immersed in the prepared plating bath for 120 minutes, and an electroless nickel-plated plate with a thickness of 25 μm was formed on the object to be plated. Phosphorus-cobalt film.

[0076] (Composition Analysis of Coating Film)

[0077] Next, the composition of the formed plating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com