Gum containing plant extract and production method of gum containing plant extract

A plant extract and chewing gum technology, which is applied in the field of chewing gum containing plant extract and its preparation, can solve the problems of unfavorable preservation and storage, large flavor influence, etc., and achieve the effects of avoiding sour and astringent taste, harmonizing sweetness, and alleviating throat discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

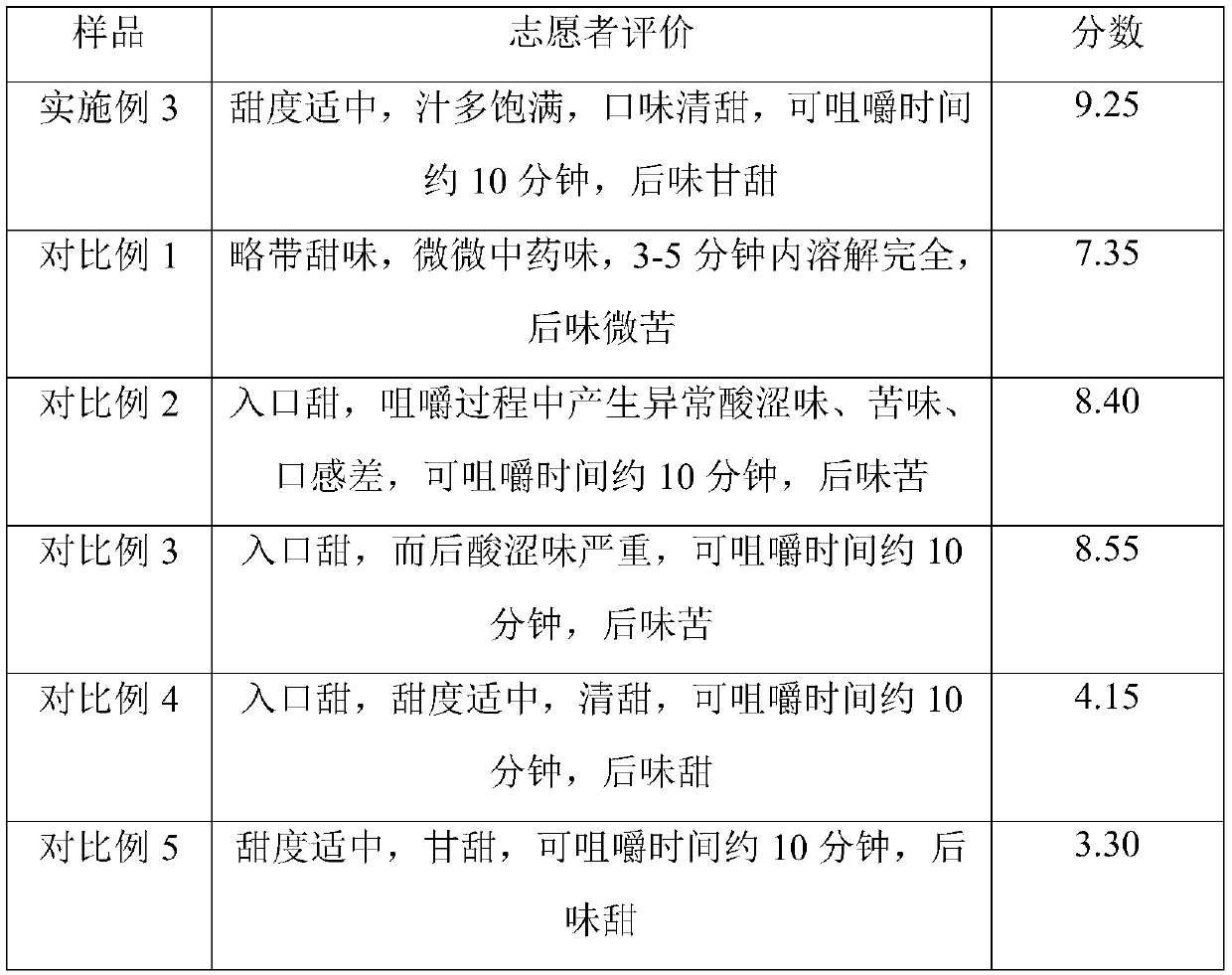

Examples

Embodiment 1

[0034] Preparation of plant extracts: S1, take 5g of Grifola frondosa, 10g of nasturtium, 3g of sweet potato leaves, 5g of tangerine peel, 3g of pomegranate peel, dry at 50-60°C, and powder; S2, take the dry powder obtained from S1 and add 10 times the volume fraction 80% ethanol, heated to 100°C, refluxed for 1.5 hours, and suction filtered to obtain an extract, repeated extraction twice, and combined extract; S3. The extract obtained in S2 was rotary evaporated and then freeze-dried.

[0035] Preparation of chewing gum: S1. Take 35g of edible gum base and place it in a water bath at 55°C and stir until the gum base melts into mucus; S2. Mix D-psicose and D-tagatose in a weight ratio of 7:3 The obtained 10g sweetener is passed through a 100-mesh sieve and added to the mucilage described in S1 while stirring; S3, 5g of the plant extract passed through a 100-mesh sieve is added, stirred for 5min, and the mixture is poured into a mold to form granules.

Embodiment 2

[0037] Preparation of plant extracts: S1, take 6g of Grifola frondosa, 11g of nasturtium, 5g of sweet potato leaves, 4g of jujube pulp, 5g of pomegranate peel, dry at 55°C, and powder; S2, add 18 times the volume fraction of the dry powder obtained from S1 to 80%-95% ethanol, heated to 100°C, refluxed for 1 hour, suction filtered to obtain an extract, repeated extraction 3 times, combined extract; S3, take the extract obtained in S2 and freeze-dry it.

[0038] Preparation of chewing gum: S1. Take 40 g of edible gum base and place it in a water bath at 60°C and stir until the gum base melts into mucus; S2. Mix D-psicose and D-tagatose in a weight ratio of 7:3 The obtained 20g sweetener is passed through a 100-mesh sieve and added to the mucus described in S1 while stirring; S3, 6g of the plant extract passed through a 100-mesh sieve is added, stirred for 5-10min, and the mixture is poured into a mold to make granules shape.

Embodiment 3

[0040] Preparation of plant extracts: S1, take 6g of Grifola frondosa, 12g of nasturtium, 5g of sweet potato leaves, 6g of tangerine peel, 5g of pomegranate peel, dry at 50-60°C, and powder; S2, take S1, add 10-20 times of the obtained dry powder Measure ethanol with a volume fraction of 80% to 95%, heat to 100°C, reflux for 0.5 to 1.5 hours, and filter with suction to obtain an extract, repeat the extraction 2 to 3 times, and combine the extracts; S3, take the extract obtained from S2 Rotary evaporated and then freeze-dried.

[0041] Preparation of chewing gum: S1. Take 45g of edible gum base and place it in a water bath at 55-65°C and stir until the gum base melts into mucus; S2. Mix D-psicose and D-tagatose in a weight ratio of 7: 3 Mix 25g of the sweetener, pass through a 100-mesh sieve and add the mucus described in S1 while stirring; S3, add 8g of the plant extract passed through a 100-mesh sieve, stir for 5-10min, pour the mixture into a mold, and make Granular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com