Washing treatment system for silicon tetrafluoride in fluorine-containing tail gas

A silicon tetrafluoride and treatment system technology, applied in the field of washing and treatment systems, can solve the problems of system equipment blockage, the exhaust gas emission index cannot meet the limit requirements, and the technical difficulty is large, so as to save costs, improve the exhaust gas purification capacity and circulation. Recycling capacity, the effect of increasing the number of gas scrubbing stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

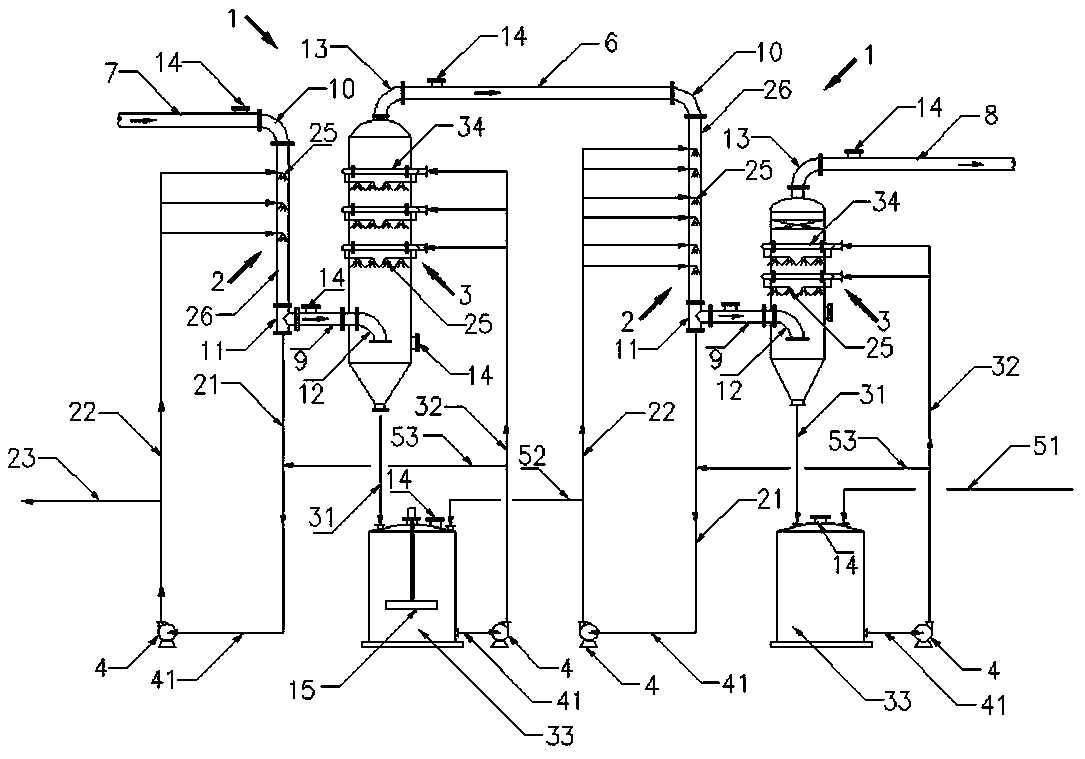

[0048] see figure 1 , a scrubbing system for silicon tetrafluoride in fluorine-containing tail gas, comprising two sets of interconnected scrubbing and absorbing devices 1; each scrubbing and absorbing device 1 includes interconnected scrubbers 2 and fluorine absorbing towers 3; the previous scrubbing The air inlet of the scrubber 2 of the absorption device 1 communicates with the fluorine-containing tail gas inlet pipe 7, and the gas outlet of the fluorine absorption tower 3 of the latter scrubbing and absorption device 1 communicates with the purified tail gas outlet pipe 8; the fluorine-containing tail gas inlet pipe 7 The initial tail gas purification is performed by connecting the scrubber intake elbow 10 with the air inlet at the top of the scrubber 2, and the two ends of the scrubber intake elbow 10 are respectively connected to the end of the fluorine-containing exhaust gas intake pipe 7 and the top of the scrubber 2 The inlet flange is connected; the purified tail gas...

Embodiment 2

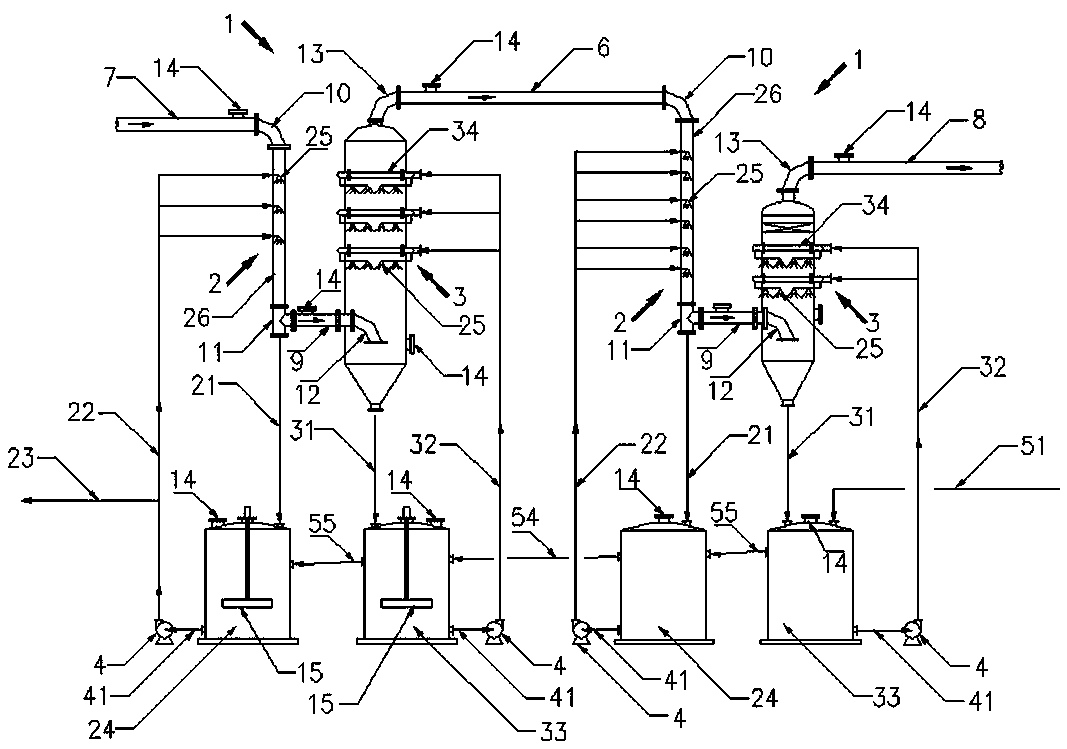

[0058] see figure 2 , the connection mode of two sets of washing and absorbing devices 1 in embodiment 2 is basically the same as that of the two sets of washing and absorbing devices 1 in embodiment 1, the difference is that in embodiment 2, the bottom of tube scrubber 26 is connected A second circulation tank 24 is also connected in series between the atmospheric leg 21 of the scrubber and the liquid inlet pipe 41 of the circulation pump, and the bottom of the tubular scrubber 26 is connected to the liquid inlet at the top of the second circulation tank 24 through the atmospheric leg 21 of the scrubber , the liquid outlet of the second circulation tank 24 communicates with the liquid inlet of the circulation pump 4 through the liquid inlet pipe 41 of the circulation pump, and the liquid outlet of the circulation pump 4 is connected to the tubular washing machine through the liquid inlet pipe 22 of the washer and its branch pipe. The liquid inlet of the spray device 25 on th...

Embodiment 3

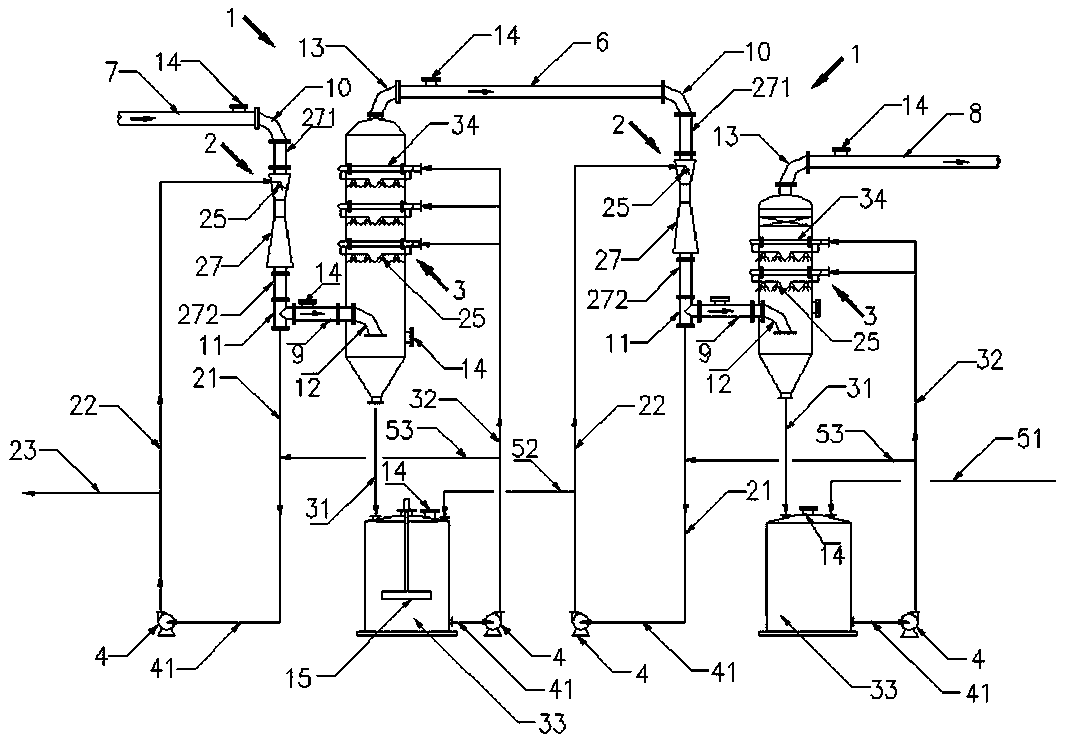

[0061] see image 3 , the connection mode of two sets of washing and absorbing devices 1 in embodiment 3 is basically the same as that of the two sets of washing and absorbing devices 1 in embodiment 1, the difference is that the scrubbers 2 in the two washing and absorbing devices 1 are Venturi Scrubber 27; the top inlet of the Venturi scrubber 27 communicates with the fluorine-containing tail gas inlet pipe 7 through the inlet pipe 271, and the bottom gas outlet communicates with the scrubber atmospheric leg 21 through the outlet pipe 272.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com