A preparation method and application of lanthanum-modified Platanus biochar

A technology of sycamore and biochar, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as unknown performance of adsorbing P, no research on adsorption capacity, etc., and achieves low cost, stable water effluent effect, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

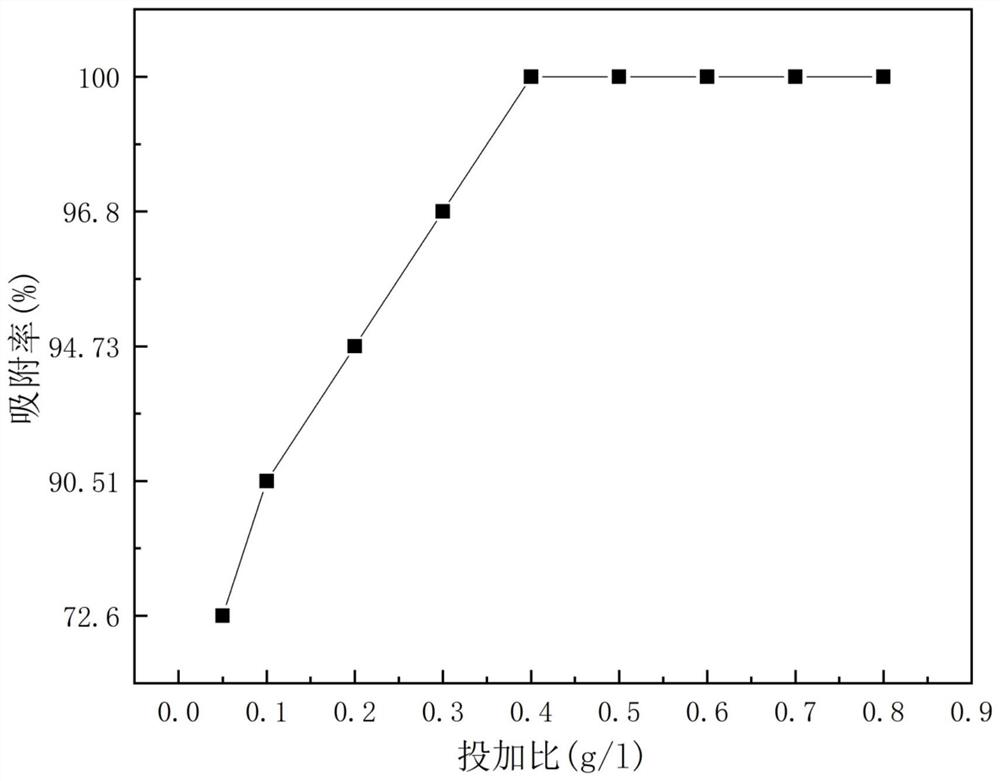

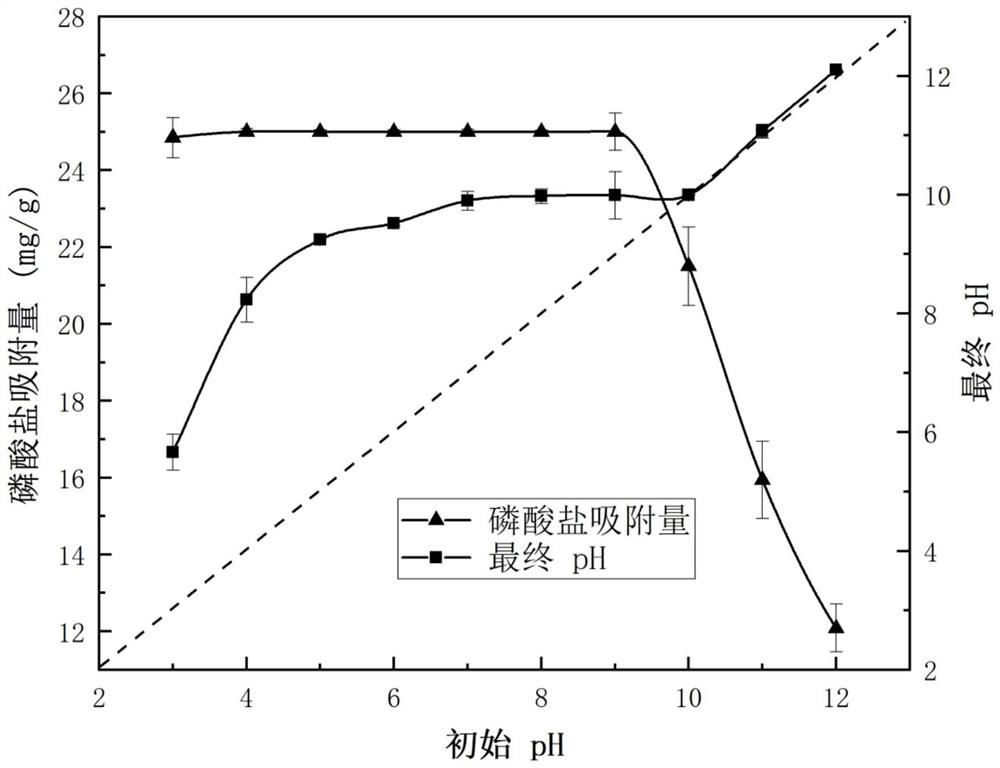

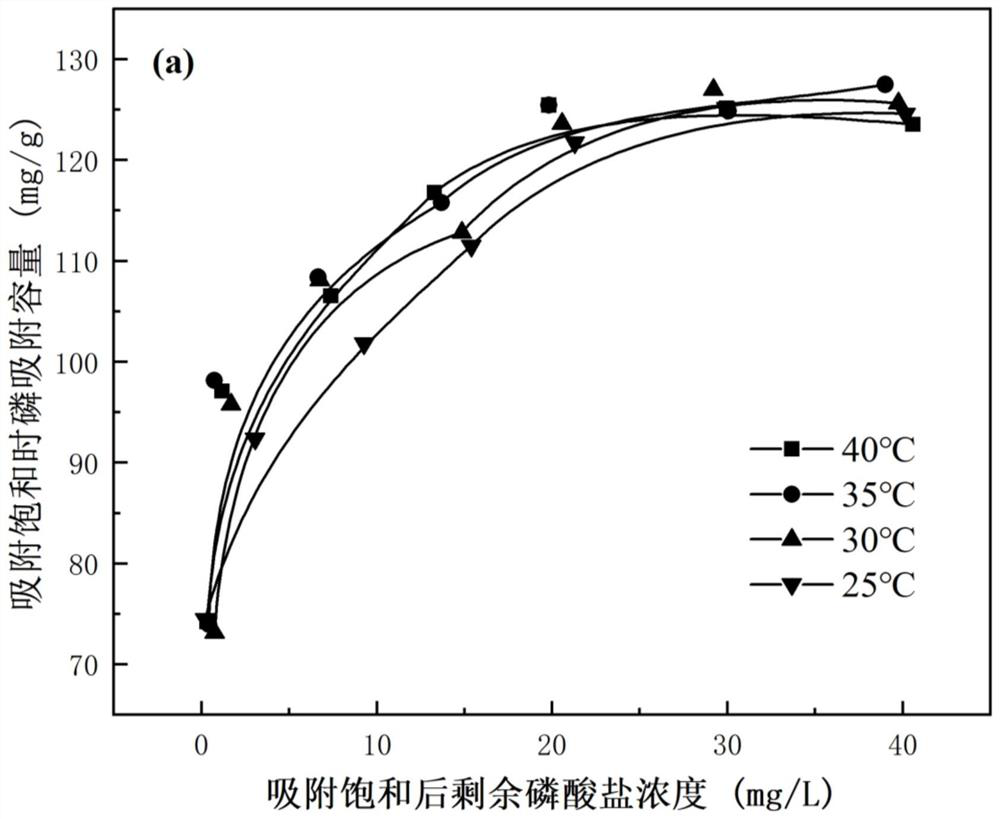

[0029] Mix dioctyl sulfosuccinate sodium salt with distilled water at a volume ratio of 1:5 to obtain a mixed solution. The mass ratio of Platanus chinensis fruit balls to the mixed solution is 1:4. Put the sycamore fruit balls into the mixed solution after being crushed. Stir at low temperature for 24 hours, separate and obtain fruit hairs, wash and dry at 105°C. The dried fruit hairs were soaked in 2.5M KOH solution for 2 hours, ultrasonicated at 40KHz for 30 minutes, and dried again. Fruit hairs were pretreated in a tube furnace at 200 °C for 30 min, and 2 Keep in the air flow for 90min, finally at 10℃·min -1 The heating rate was increased to 600 ° C for 2 h. The obtained biochar TC was ground with a 200-mesh sieve and washed to neutral drying. Add 300mgTC to 50mL of 0.2M La(NO 3 ) 3 ·6H 2 In a Erlenmeyer flask of O, 1M NaOH was added by co-precipitation method to maintain the pH at 11, and magnetically stirred for 24h. After centrifugation at 6000 rpm, a solid preci...

example 2

[0032] Mix dioctyl sulfosuccinate sodium salt with distilled water at a volume ratio of 1:5 to obtain a mixed solution. The mass ratio of Platanus chinensis fruit balls to the mixed solution is 1:4. Put the sycamore fruit balls into the mixed solution after being crushed. Stir at low temperature for 24 hours, separate and obtain fruit hairs, wash and dry at 105°C. The dried fruit hairs were soaked in 2.5M KOH solution for 2 hours, ultrasonicated at 40KHz for 30 minutes, and dried again. Fruit hairs were pretreated in a tube furnace at 200 °C for 30 min, and 2 Keep in the air flow for 90min, finally at 10℃·min-1 The heating rate was increased to 600 ° C for 2 h. The obtained biochar TC was ground with a 200-mesh sieve and washed to neutral drying. Add 300mgTC to 50mL of 0.2M La(NO 3 ) 3 ·6H 2 In a Erlenmeyer flask of O, 1M NaOH was added by co-precipitation method to maintain the pH at 11, and magnetically stirred for 24h. After centrifugation at 6000 rpm, a solid precipi...

example 3

[0035] Mix dioctyl sulfosuccinate sodium salt with distilled water at a volume ratio of 1:5 to obtain a mixed solution. The mass ratio of Platanus chinensis fruit balls to the mixed solution is 1:4. Put the sycamore fruit balls into the mixed solution after being crushed. Stir at low temperature for 24 hours, separate and obtain fruit hairs, wash and dry at 105°C. The dried fruit hairs were soaked in 2.5M KOH solution for 2 hours, ultrasonicated at 40KHz for 30 minutes, and dried again. Fruit hairs were pretreated in a tube furnace at 200 °C for 30 min, and 2 Keep in the air flow for 90min, finally at 10℃·min -1 The heating rate was increased to 600 ° C for 2 h. The obtained biochar TC was ground with a 200-mesh sieve and washed to neutral drying. Add 300mgTC to 50mL of 0.2M La(NO 3 ) 3 ·6H 2 In a Erlenmeyer flask of O, 1M NaOH was added by co-precipitation method to maintain the pH at 11, and magnetically stirred for 24h. After centrifugation at 6000 rpm, a solid preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com