Composite building waterproof and heat-preserving material and preparation method thereof

A technology for thermal insulation materials and building waterproofing. It is applied in the direction of building thermal insulation materials, thermal insulation, construction, etc. It can solve the problems of poor fire resistance, insufficient strength, and endangering the internal structure of buildings, so as to improve mechanical properties and corrosion resistance, and improve thermal insulation and waterproofing. Performance, the effect of prolonging the degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

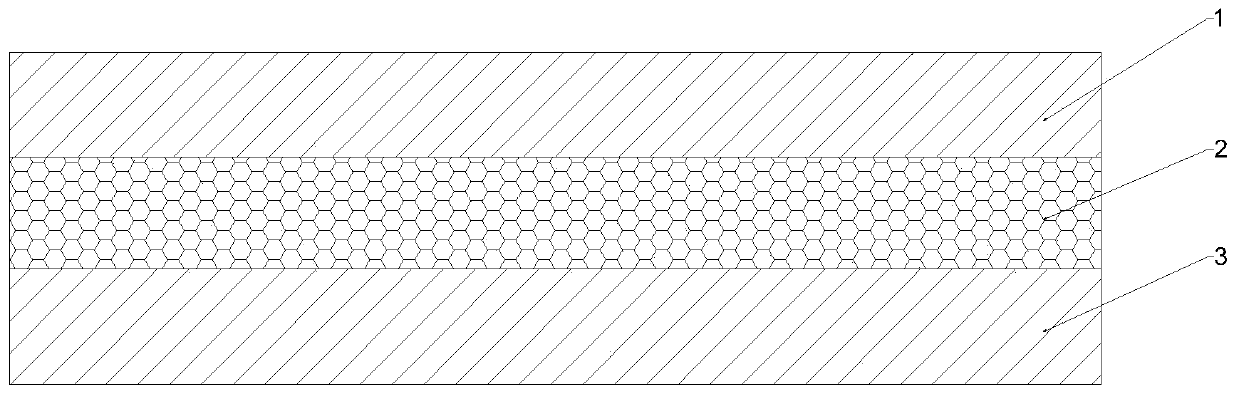

[0036] A composite building waterproof and thermal insulation material is composed of upper, middle and lower layers, wherein the upper and lower layers are waterproof layers, and the middle layer is composed of nano-ceramic mycelium heat insulation layer.

[0037] The waterproofing layer is made of the following weights:

[0038] Expanded perlite 60kg

[0039] Sodium methyl silicate 30kg

[0040] Polyvinyl alcohol 20kg

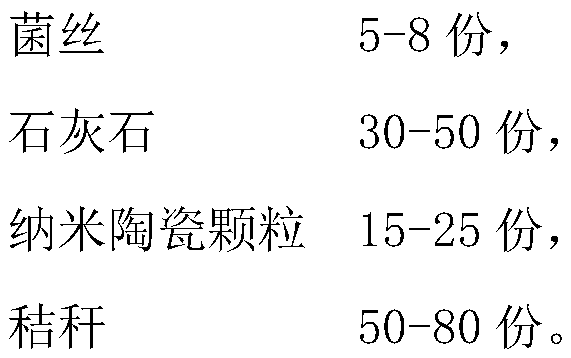

[0041] The mycelium insulation layer is made of the following weights:

[0042]

[0043]

[0044] The particle size of the nano ceramic particles is 20nm.

[0045] The nano-ceramic mycelium insulation layer is prepared by the following steps:

[0046] 1) Crush 50kg of limestone to screen out 20-mesh particles; crush 80kg of wheat straw to screen out 10-mesh particles.

[0047] 2) Preparation of culture material: uniformly disperse limestone powder and 25kg of nano-ceramic particles in water, add wheat straw powder under stirring, and adjust the moi...

Embodiment 2

[0057] A composite building waterproof and thermal insulation material is composed of upper, middle and lower layers, wherein the upper and lower layers are waterproof layers, and the middle layer is composed of nano-ceramic mycelium heat insulation layer.

[0058] The waterproof layer is made of the following materials in parts by weight:

[0059] Expanded Perlite 57kg

[0060] Sodium methyl silicate 28kg

[0061] Polyvinyl alcohol 17kg

[0062] The mycelium insulation layer is made of the following materials in parts by weight:

[0063]

[0064] The particle size of the nano ceramic particles is 30nm.

[0065] The nano-ceramic mycelium insulation layer is prepared by the following steps:

[0066]1) Crush 45kg of limestone to screen out 30-mesh particles; crush 70kg of wheat straw to screen out 10-mesh particles.

[0067] 2) Preparation of culture material: uniformly disperse limestone powder and 23kg of nano-ceramic particles in water, add wheat straw powder under st...

Embodiment 3

[0077] A composite building waterproof and thermal insulation material is composed of upper, middle and lower layers, wherein the upper and lower layers are waterproof layers, and the middle layer is composed of nano-ceramic mycelium heat insulation layer.

[0078] The waterproof layer is composed of the following materials in parts by weight:

[0079] Expanded Perlite 55kg

[0080] Sodium methyl silicate 25kg

[0081] Polyvinyl alcohol 15kg

[0082] The mycelium insulation layer is made up of the following materials in parts by weight:

[0083]

[0084] The particle size of the nano ceramic particles is 50nm.

[0085] The nano-ceramic mycelium insulation layer is prepared by the following steps:

[0086] 1) Grinding 40kg of limestone to screen out 35 mesh particles; crushing 65kg of wheat straw to screen out 10 mesh particles.

[0087] 2) Preparation of culture material: uniformly disperse limestone powder and 20kg of nano-ceramic particles in water, add wheat straw p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com