Ethyl linoleate catalytically synthesized by using ionic liquid microemulsion and preparation method thereof

A technology of ethyl linoleate and ionic liquid, which is applied in the field of catalyzed synthesis of ethyl linoleate and its preparation with ionic liquid microemulsion, can solve problems such as unfavorable industrial production, and achieve improved conversion rate, accelerated reaction rate, and processing The effect of low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

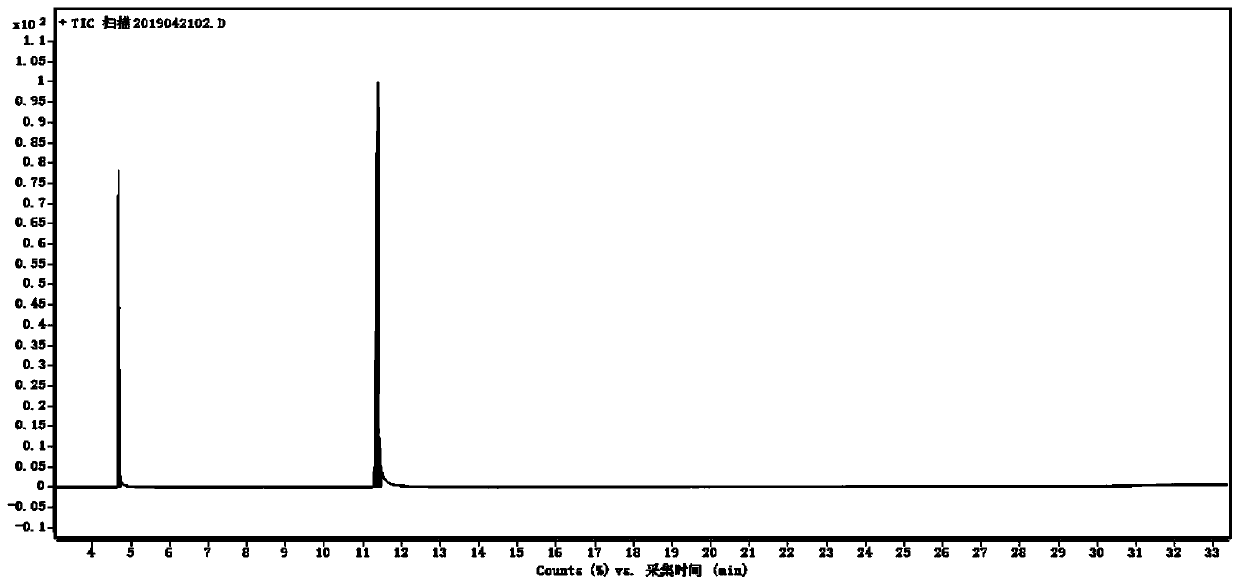

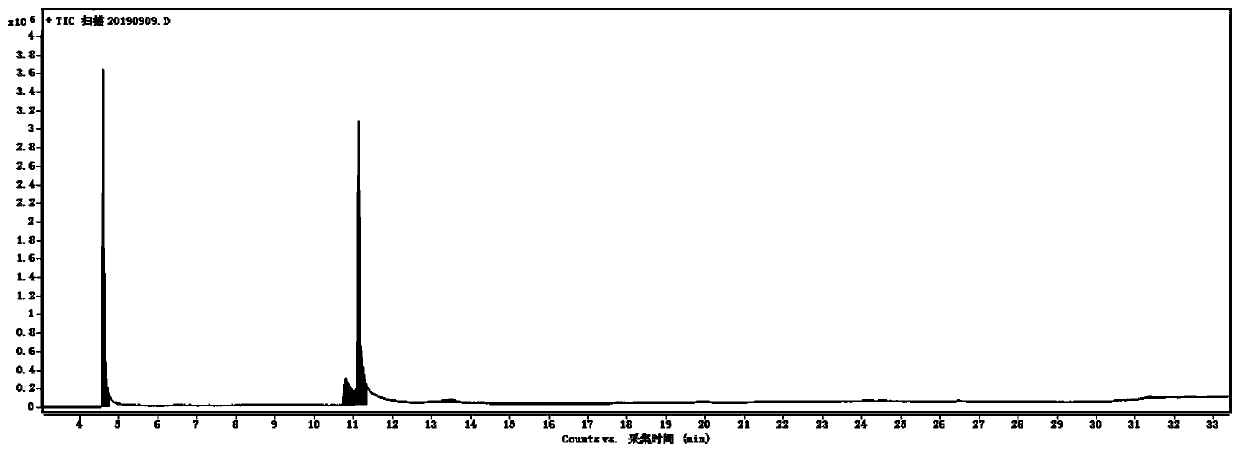

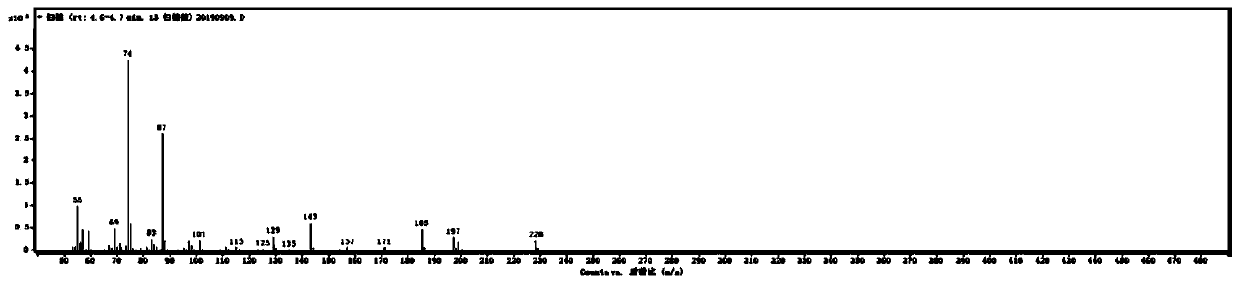

Image

Examples

Embodiment 1

[0034] Ionic liquid microemulsion components and their dosage: hydrophilic ionic liquid [Hmim]HSO 4 (Purchased from Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences) 6 parts by weight, 5 parts by weight of cyclohexane, and 24 parts by weight of conventional surfactant TX-100 (purchased from Guangzhou Jingke Chemical Glass Instrument Company).

[0035] Under the condition of 25℃, mix the surfactant TX-100 and the imidazole ionic liquid 1-hexyl-3-methylimidazole bisulfate evenly, stirring at 700 rpm, stirring for 5 minutes, to obtain a clear and transparent mixture. Then add cyclohexane and mix it uniformly at a stirring speed of 700 rpm and stir for 5 minutes to obtain a clear and transparent ionic liquid microemulsion with good high temperature stability.

[0036] Take 7.6049g of ionic liquid microemulsion, 5.6256g of linoleic acid, and 5.7181g of ethanol to stir and mix, and carry out the esterification reaction under stirring, wherein the stirring speed is 700 rp...

Embodiment 2

[0039] Ionic liquid microemulsion components and their dosage: hydrophilic ionic liquid [Hmim]HSO 4 (Purchased from Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences) 2 parts by weight, 1 part by weight of cyclohexane, and 4 parts by weight of conventional surfactant TX-100 (purchased from Guangzhou Jingke Chemical Glass Instrument Company).

[0040] Under the condition of 25℃, mix the surfactant TX-100 and the imidazole ionic liquid 1-hexyl-3-methylimidazole bisulfate evenly, stirring at 700 rpm, stirring for 5 minutes, to obtain a clear and transparent mixture. Then add cyclohexane and mix it uniformly at a stirring speed of 700 rpm and stir for 5 minutes to obtain a clear and transparent ionic liquid microemulsion with good high temperature stability.

[0041] Take 6.284 g of ionic liquid microemulsion, 5.7845 g of linoleic acid, and 5.6226 g of ethanol to stir and mix, and carry out the esterification reaction under stirring, wherein the stirring speed is 700 re...

Embodiment 3

[0044] Ionic liquid microemulsion components and dosage: hydrophilic ionic liquid [Bmim]HSO 4 (Purchased from Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences) 6 parts by weight, 5 parts by weight of cyclohexane, and 24 parts by weight of conventional surfactant TX-100 (purchased from Guangzhou Jingke Chemical Glass Instrument Company).

[0045] Under the condition of 25℃, mix the surface active agent TX-100 and the imidazole ionic liquid 1-butyl-3-methylimidazole hydrogen sulfate evenly at a stirring speed of 1000 rpm, stirring for 5 minutes, to obtain a clear and transparent mixture , And then add cyclohexane and mix it evenly at a stirring speed of 1000 revolutions per minute and stir for 5 minutes to obtain a clear and transparent ionic liquid microemulsion with good high temperature stability.

[0046] Take 7.5950 g of ionic liquid microemulsion, 5.6230 g of linoleic acid, and 5.5346 g of ethanol to stir and mix, and carry out the esterification reaction under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com