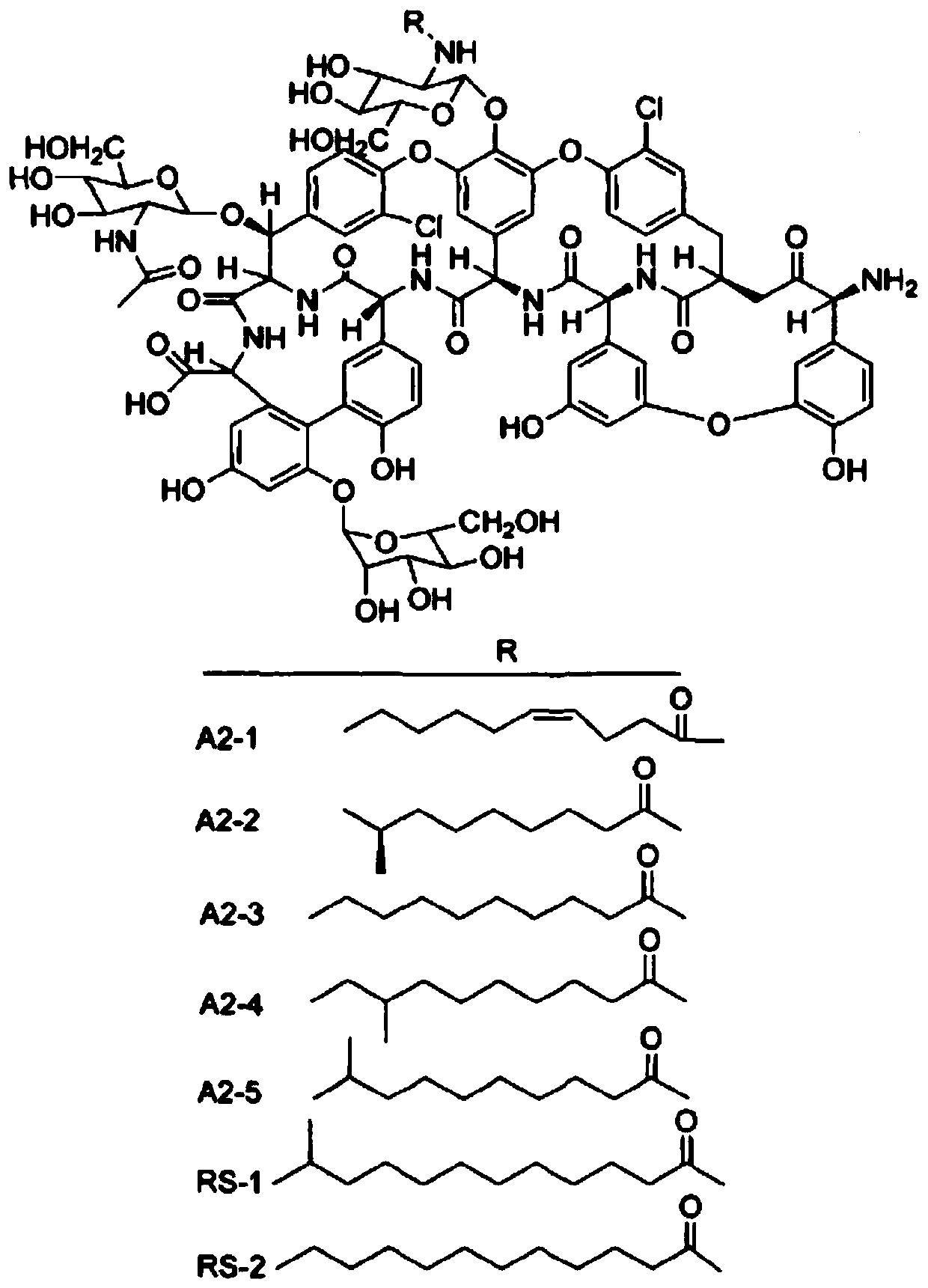

Fed-batch method for improving fermentation yield of teicoplanin

A technology of teicoplanin and feeding material is applied in the field of feeding feeding for improving the fermentation yield of teicoplanin, which can solve the problem of high cost and achieve the effects of low cost, improving fermentation yield and promoting energy material metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A feeding method for improving the fermentation yield of teicoplanin, specifically comprising the following steps:

[0021] 1) Seed culture: inoculate Actinoplanes teichomyceticus into the seed medium, and cultivate in a 30L test tank with a culture period of 50±16h to obtain seed liquid;

[0022] Seed medium formula (in parts by mass): 2.0 parts of soybean cake powder, 0.5 parts of yeast powder, 0.5 parts of peptone, 2.5 parts of glucose, 2 parts of starch, 0.4 parts of sodium chloride, 0.02 parts of potassium dihydrogen phosphate, 0.3 parts of calcium carbonate share;

[0023] Culture conditions: temperature 28°C, ventilation volume v:v=1:1.5, tank pressure 0.05Mpa, rotation speed 300rpm, initial pH value 7.2;

[0024] 2) Fermentation culture: Inoculate the cultivated seed liquid into the fermentation medium according to the inoculation amount of 6%, and cultivate it in a 50L test tank, and the culture period is 90-102h;

[0025] Fermentation medium formula (in part...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is:

[0034] When the fermentation culture reaches 20-30 hours, start to feed 15% sodium acetate solution, and the flow rate is 0.29mL / (h·L);

[0035] When the fermentation culture reaches 30-50h, the flow acceleration rate changes to 0.23mL / (h·L);

[0036] When the fermentation culture reaches 50-90h, the flow acceleration rate changes to 0.17mL;

[0037] The average tank batch yield of Example 2 was 4.89 g / L.

Embodiment 3

[0039] The difference between embodiment 3 and embodiment 1 is:

[0040] When the fermentation culture reaches 30-40 hours, start to feed 15% sodium acetate solution, and the flow rate is 0.29mL / (h·L);

[0041] When the fermentation culture reaches 40-60h, the flow acceleration rate changes to 0.23mL / (h·L);

[0042] When the fermentation culture reaches 60-102h, the flow acceleration rate changes to 0.17mL.

[0043] The average tank batch yield of Example 3 was 4.83 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com