Polyolefin material with controllable degradation unit and high monomer utilization rate and preparation method thereof

A utilization rate and polyolefin technology, applied in the field of polyolefin materials, can solve problems such as uneven distribution of functional groups, wide molecular weight distribution, uncontrollable molecular weight of polymers, etc., achieve high monomer utilization rate, promote degradation, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a degradable polyolefin with a controllable number of degradation units and a high monomer utilization rate, comprising the following steps:

[0032] The cycloketene acetal, free radical initiator and chain transfer reagent are dissolved in a solvent and then reacted with olefin or olefin derivative to obtain a degradable polyolefin material.

[0033] In the invention, firstly, the cycloketene acetal, the free radical initiator and the chain transfer reagent are dissolved in a solvent to obtain a mixed solution.

[0034] Wherein, the cycloalkene acetal is selected from one or more of 2-methylene-1,3-dioxetane, 2-methylene-1,3,6-trioxetane kind.

[0035] The free radical initiator is selected from azobisisobutyronitrile, azobisisoheptanonitrile, benzoyl peroxide, lauroyl peroxide, cumene hydroperoxide, tert-butyl hydroperoxide, dihydroperoxide tert-butyl, dicumyl peroxide, tert-butyl peroxybenzoate, tert-butyl peroxy-valera...

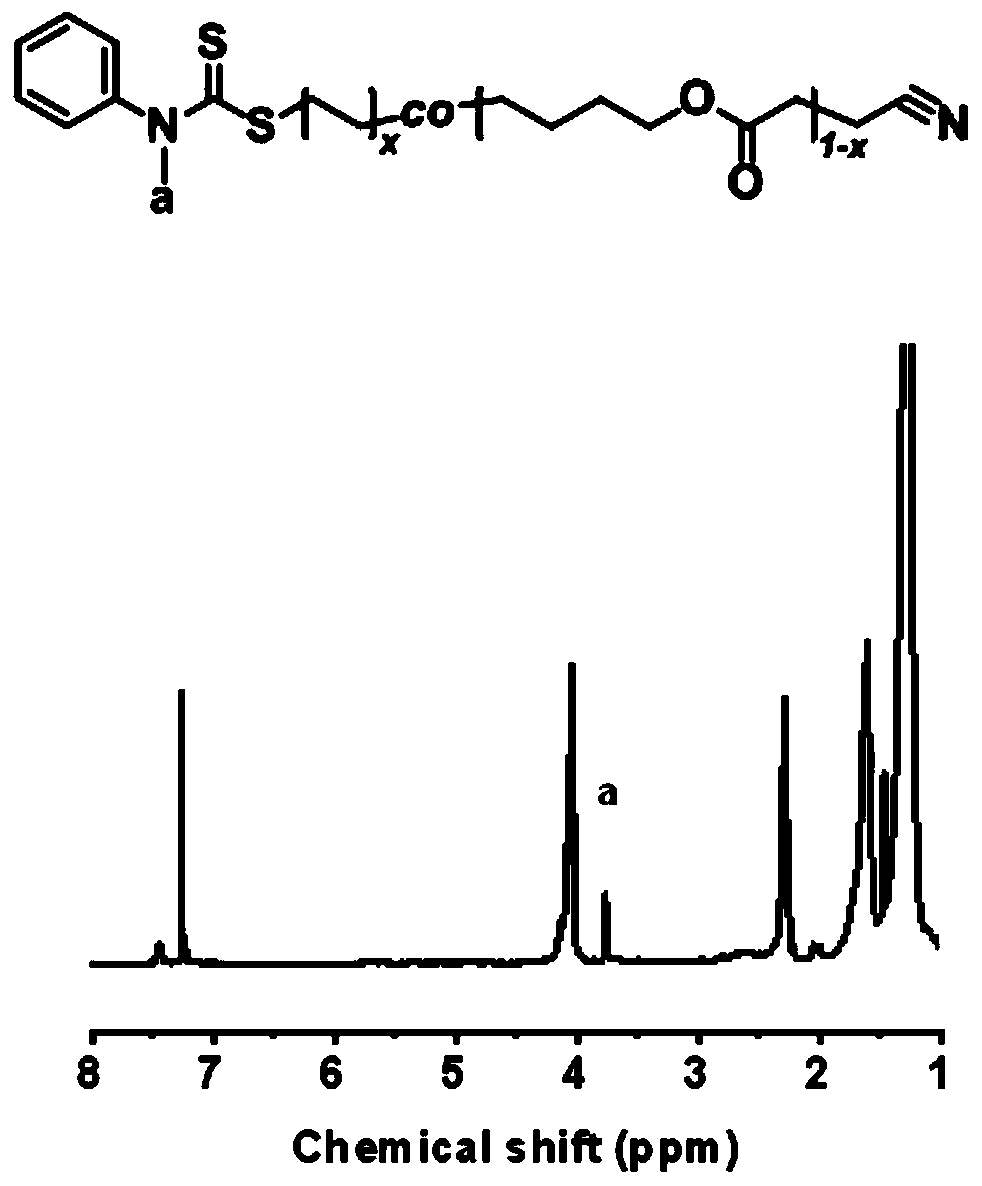

Embodiment 1

[0062] 0.58g 2-methylene-1,3-dioxetane, 3.2g dimethyl carbonate, 0.007g azobisisobutyronitrile and 0.02g cyanomethyl-N-methyl-N-phenyl Mix dithiocarbamate evenly, place in a 100ml stainless steel reactor, feed ethylene until the pressure reaches 3MPa, heat the mixture to 70°C under stirring, continue feeding ethylene to keep the reactor pressure constant, and react for 22 hours .

[0063] The reactor was cooled to room temperature, the crude polymerization mixture was precipitated in methanol, then centrifuged to remove the methanol, the resulting polymer was dissolved in chloroform, again precipitated in excess methanol, the methanol was removed and dried under vacuum. The degradable polyolefin 1 can be obtained.

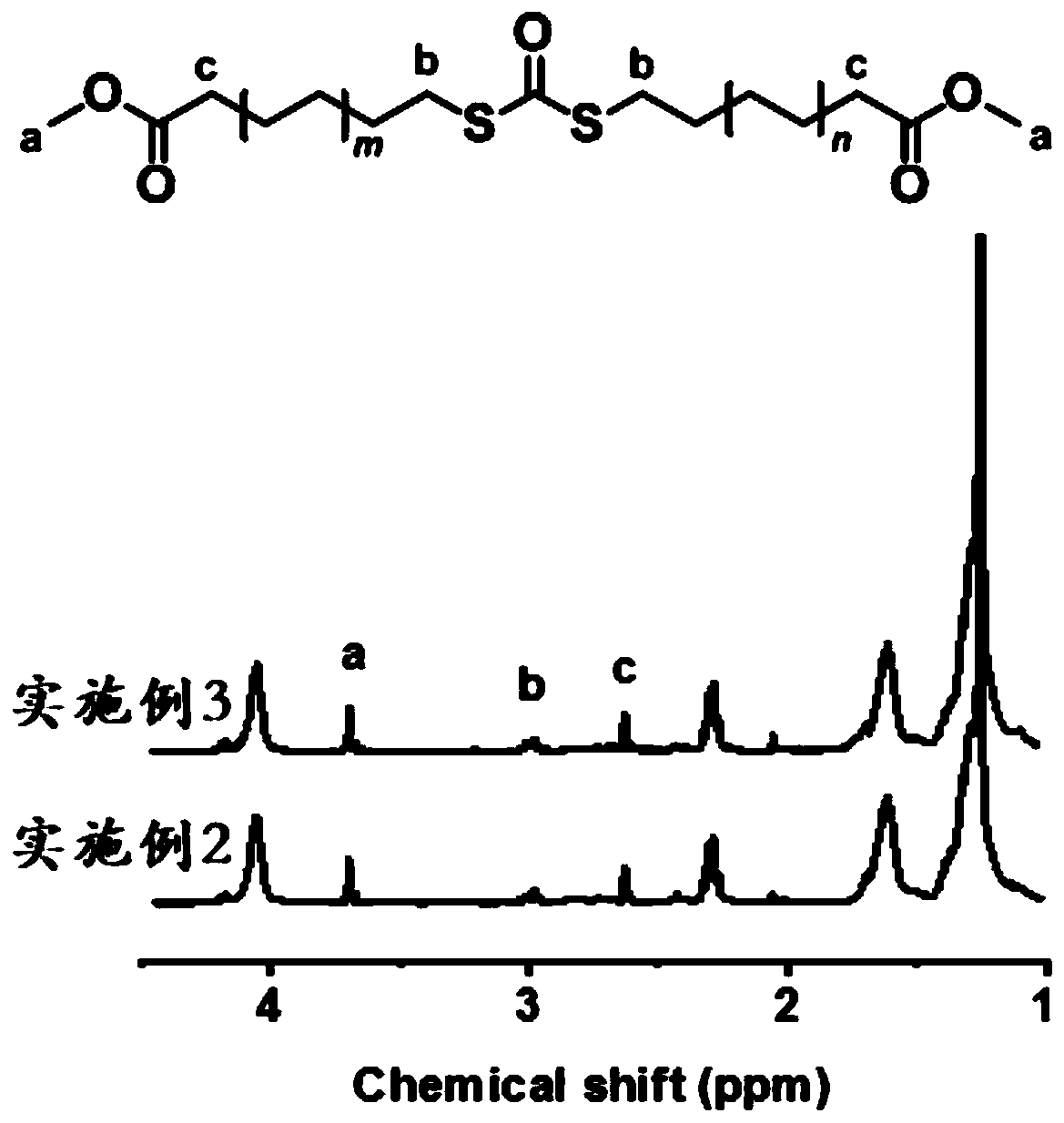

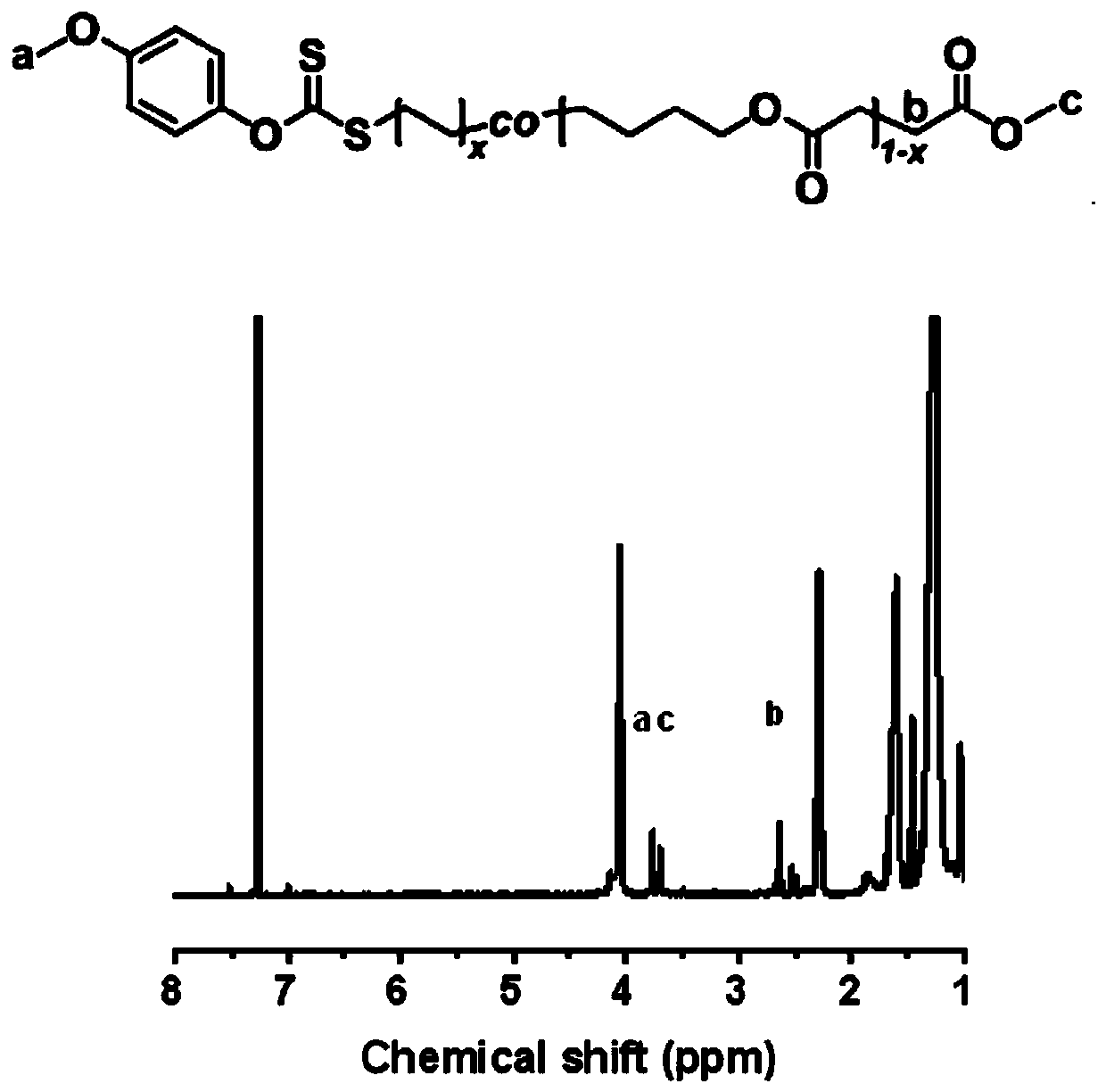

Embodiment 2

[0065] Experiment in a method similar to Example 1, except that cyanomethyl-N-methyl-N-phenyldithiocarbamate is changed into ethoxy xanthate to obtain degradable poly Alkenes 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com