Pressure canned single-component polyurethane foam capable of being sprayed on surface and preparation method and application thereof

A technology of polyurethane foam and surface spraying, applied in the field of single-component polyurethane foam, can solve the problems of inability to achieve spraying, difficult to carry, complicated operation, etc., and achieve the effects of stable properties, easy portability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

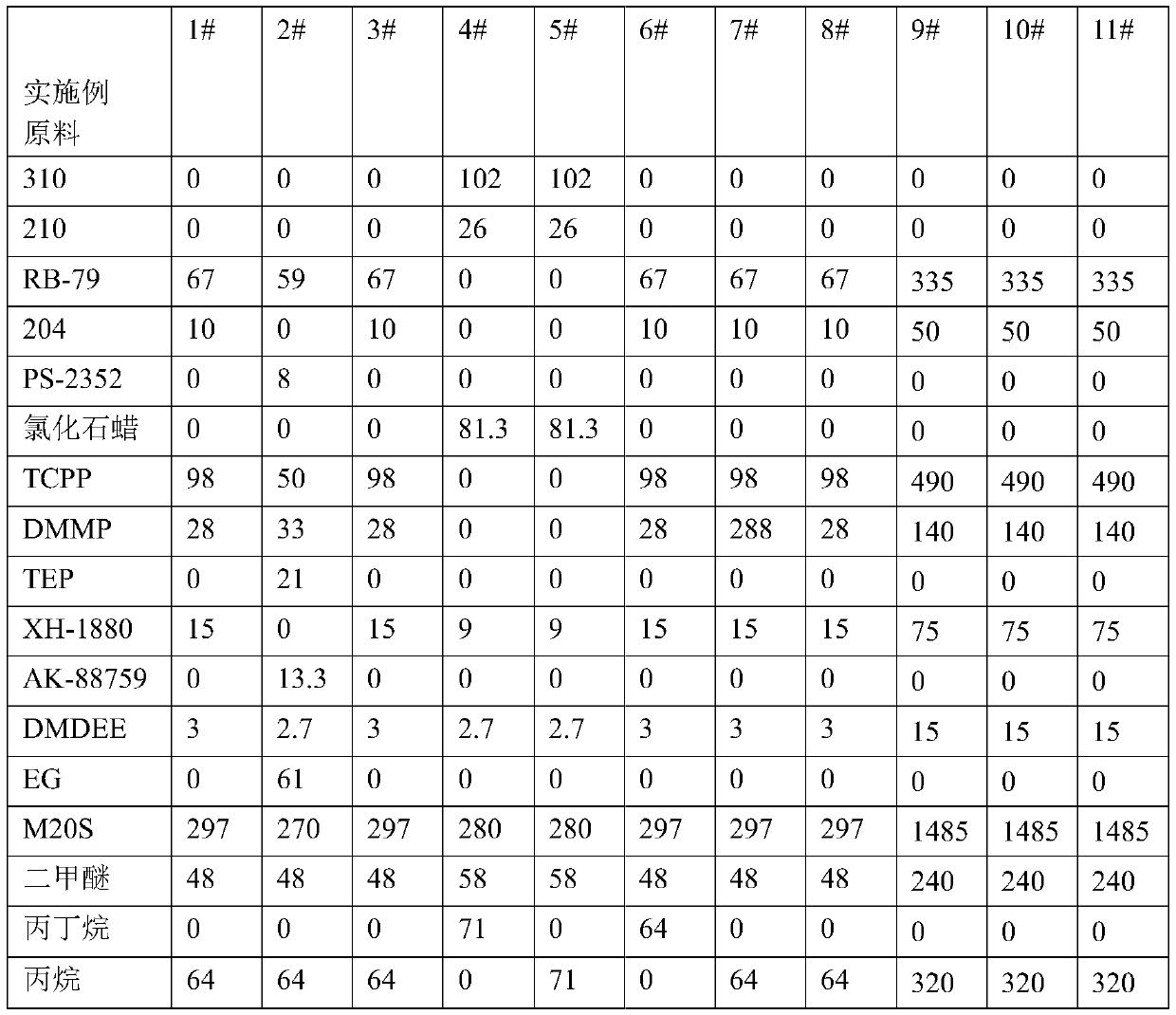

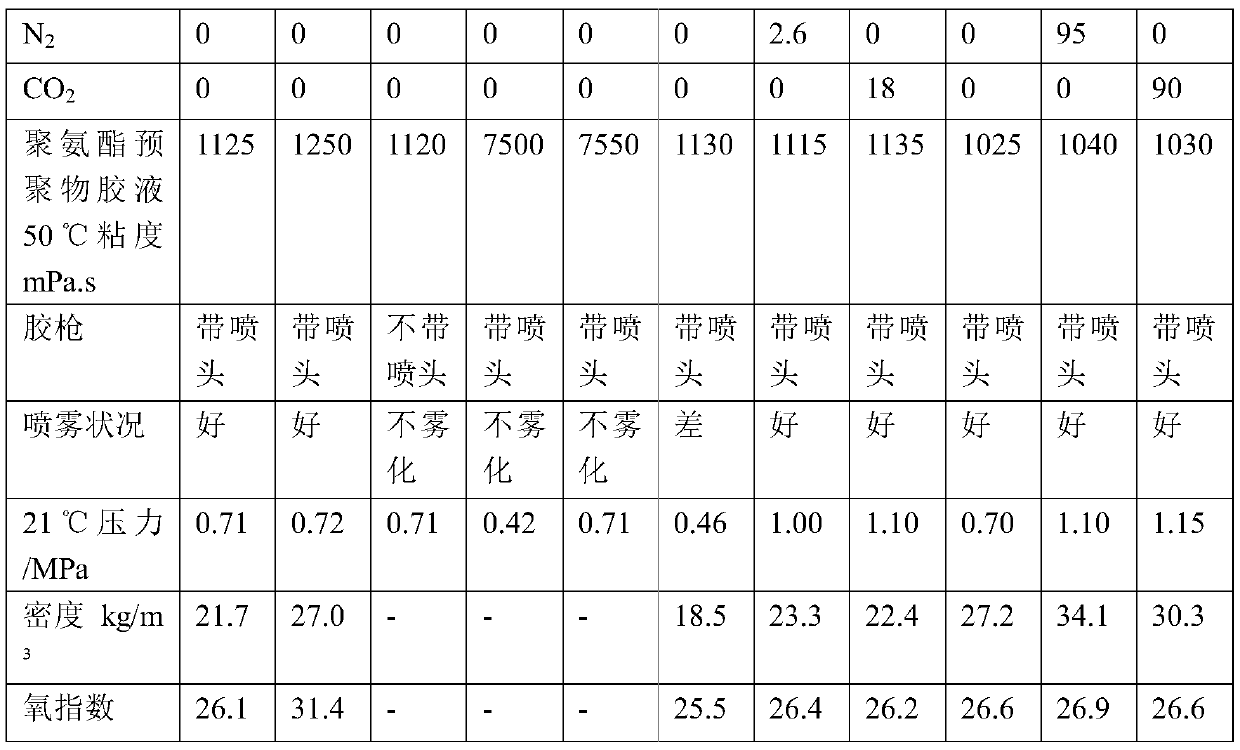

Embodiment 1

[0054] The pressure canned surface-sprayable single-component polyurethane foam of the present invention and its preparation method, according to the 1# formula in Table 1, 67g flame-retardant polyester polyol RB-79, 10g polyether polyol 204, 98g liquid flame retardant TCPP, 28g of liquid flame retardant DMMP, 15g of foam stabilizer XH-1880, and 3g of catalyst DMDEE were mixed uniformly to obtain 221g of combined polyether. Then add 221g combined polyether and 297g polymethylene polyphenylisocyanate M20S into a 750ml aerosol can, seal the valve, pour in 48g blowing agent dimethyl ether, shake and mix for 5 minutes, and place it at room temperature to cool to After standing at room temperature for 24 hours, add 64g of booster propane to get this product. Then use a glue gun with a spray head to spray on the cardboard to form a 2-3cm thick foam, and cure for 72 hours.

[0055] After testing, the viscosity of polyurethane prepolymer glue is 1125mPa.s at 50°C, the pressure inside...

Embodiment 2

[0057] Press 2# formula in table 1, with 59g flame retardant polyester polyol RB-79, 8g polyester polyol PS-2352, 50g liquid flame retardant TCPP, 33g liquid flame retardant DMMP, 21g liquid flame retardant TEP, 61g of expandable graphite, 13.3g of foam stabilizer AK-88759, and 2.7g of catalyst DMDEE were mixed uniformly to obtain 248g of composite polyether. Add 248g combined polyether and 270g polymethylene polyphenylisocyanate M20S into a 750ml aerosol can, seal the valve, pour in 48g blowing agent dimethyl ether, shake and mix for 5 minutes, and place it at room temperature to cool to After standing at room temperature for 24 hours, add 64g of booster propane to get this product. Then use a glue gun with a spray head to spray on the cardboard to form a 2-3cm thick foam, and cure for 72 hours.

[0058] After testing, the viscosity of the polyurethane prepolymer glue is 1250mPa.s at 50°C, the pressure inside the aerosol can is 0.72Mpa at 21°C, and the foam density after spr...

Embodiment 3

[0061] According to the 3# formula (same as formula 1#) in Table 1, the product is obtained, and it is shot out with a general single-component polyurethane foam caulking agent glue gun (without a nozzle), and the glue liquid that is shot out is strip-shaped and cannot be atomized. Less than surface sprayable effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Foam density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com