High-temperature dust-containing waste gas emission purification method and device thereof

An exhaust gas emission and purification device technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of secondary pollution of washing liquid, high equipment operating costs, and high operating costs, so as to avoid secondary emission pollution, Easy assembly and operation, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

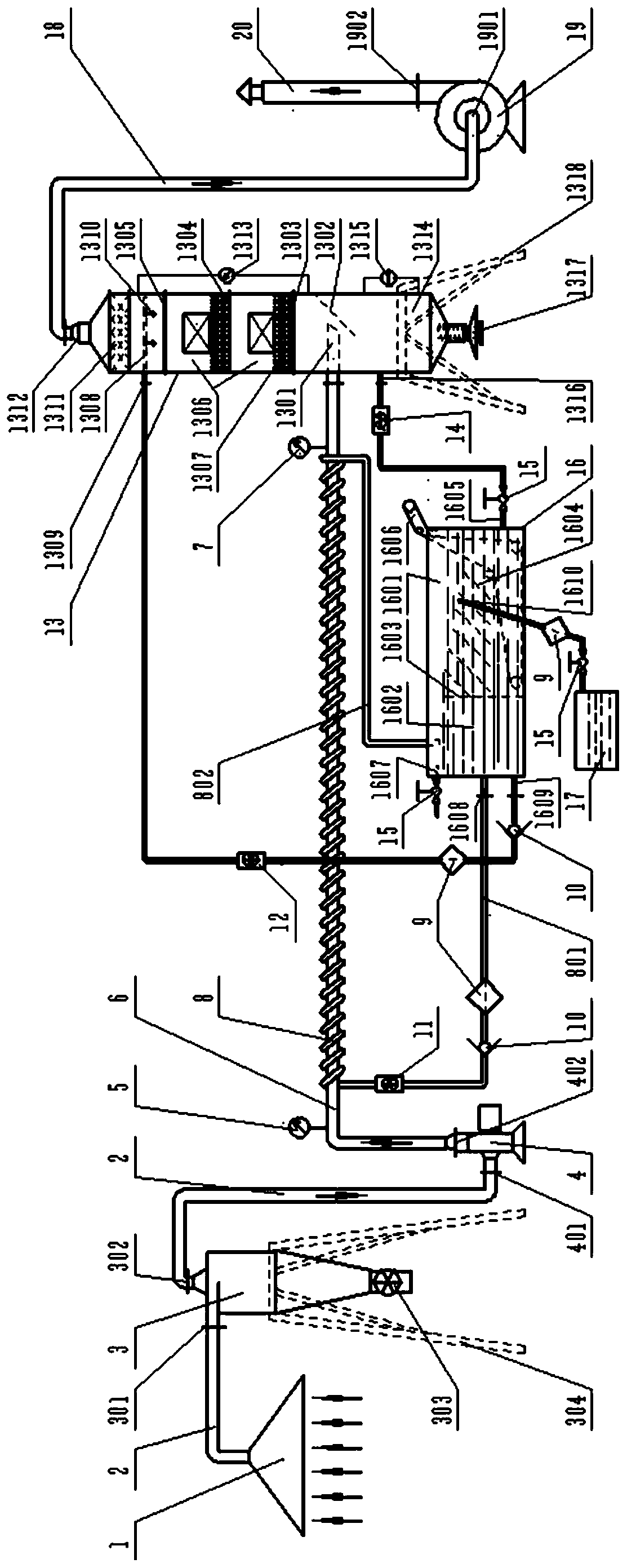

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

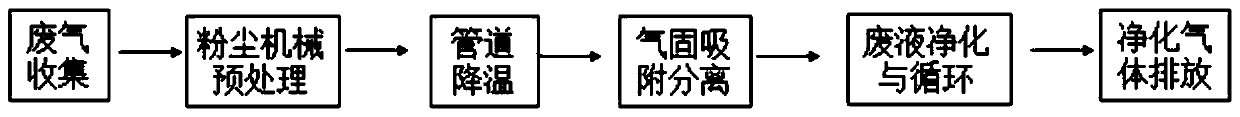

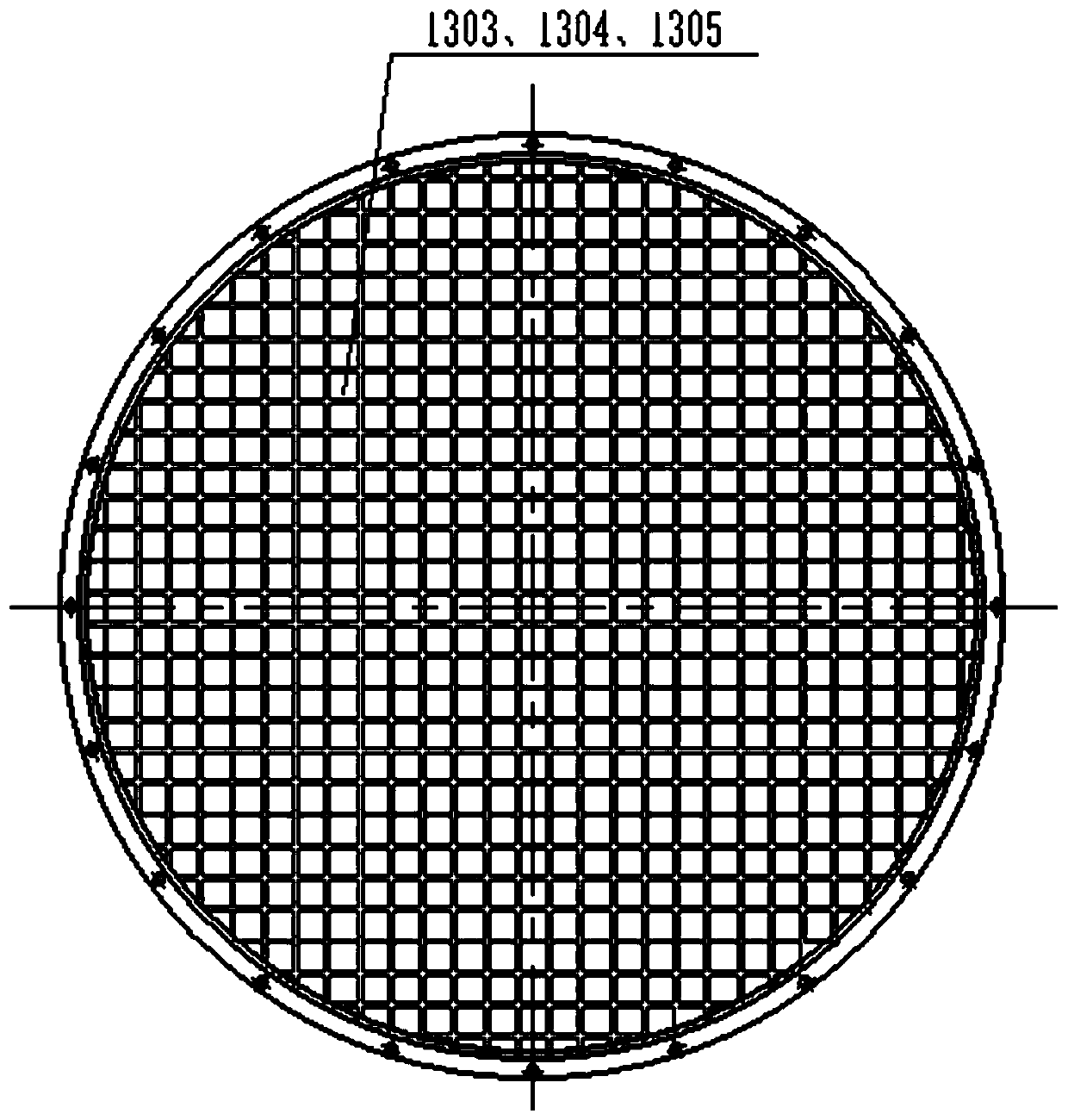

[0031] See attached figure 1 , attached figure 2 , The invention provides a method for purifying high-temperature dusty waste gas discharge, comprising the following process steps: waste gas collection, dust mechanical pretreatment, pipeline cooling, gas-solid adsorption separation, waste liquid purification and circulation, and purified gas discharge. Specifically, the high-temperature dust-laden exhaust gas generated by the equipment in the workshop is collected by the gas collecting hood 1; under the action of the first-stage centrifugal fan 4, the cyclone dust removal device 3 is used for pretreatment, so that the dust particles with a particle size of 100 μm or more are in the inertia Under the action of gravity and gravity, it is discharged from the discharge valve 303 at the bottom; other high-temperature dust-containing gas is cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com