Nitrogen and phosphorus removal composite filler and preparation method thereof

A composite filler, nitrogen and phosphorus removal technology, applied in the field of environmental protection and material science, can solve the problems of difficult microbial treatment, high cost of chemical treatment, low plant absorption efficiency, etc., and achieve fast adsorption rate, high safety, strong Adsorptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: A nitrogen and phosphorus removal composite filler and its preparation method, the raw material components and quality of the nitrogen and phosphorus removal composite filler are: steel slag powder 25kg; zeolite particles 43kg; pearl expanded rock powder 6kg; clay 12kg; dolomite powder 12kg; porous ball 1.2kg.

[0040] Among them, the particle size of steel slag, expanded pearlite and dolomite is less than 0.15mm, specifically about 0.14mm; the content of montmorillonite in expanded pearlite is about 83%; the clay is clean clay, free of organic matter, humus and other impurities. It is required that after the pearl expanded rock is fired, the volume expansion is about 11 times.

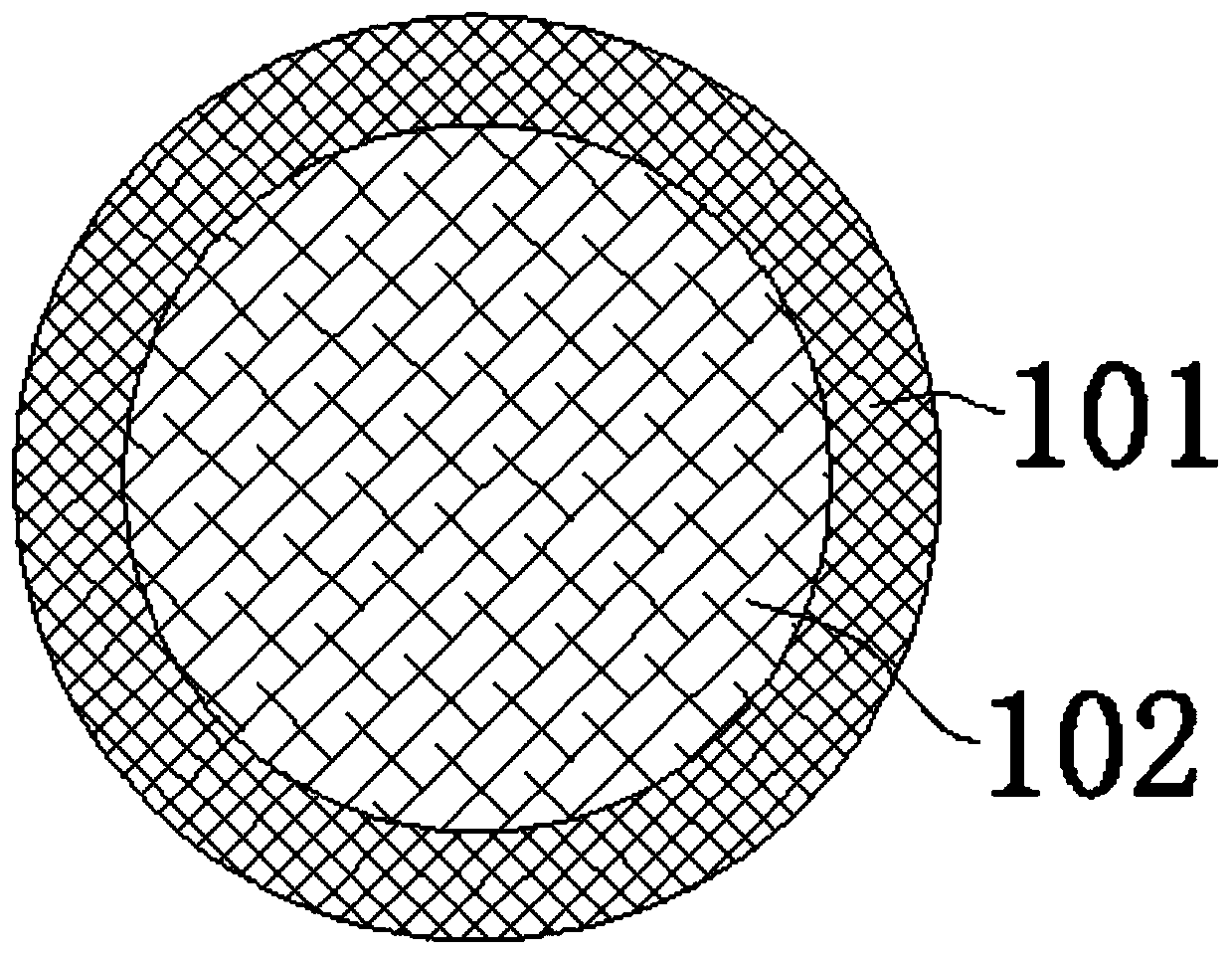

[0041] refer to figure 1 , the particle size of the porous balls is 0.45cm, and the porous balls include stainless steel silk balls 102 . The outer surface of the stainless steel wire ball 102 is covered with a high temperature resistant glass cloth 101, and the high temperature re...

Embodiment 2

[0051] Example 2: A nitrogen and phosphorus removal composite filler and its preparation method, the raw material components and quality of the nitrogen and phosphorus removal composite filler are: steel slag powder 20kg; zeolite particles 40kg; pearl expanded rock powder 5kg; clay 10kg; dolomite powder 10kg; porous ball 1kg.

[0052] Among them, the particle size of steel slag, expanded pearlite and dolomite is less than 0.15mm, specifically about 0.14mm; the content of montmorillonite in expanded pearlite is about 83%; the clay is clean clay, free of organic matter, humus and other impurities. It is required that after the pearl expanded rock is fired, the volume expansion is about 11 times.

[0053] refer to figure 1 , the particle size of the porous balls is 0.45cm, and the porous balls include stainless steel silk balls 102 . The outer surface of the stainless steel wire ball 102 is covered with a high temperature resistant glass cloth 101, and the high temperature resist...

Embodiment 3

[0061] Example 3: A nitrogen and phosphorus removal composite filler and its preparation method. The raw material components and quality of the nitrogen and phosphorus removal composite filler are: steel slag powder 25kg; zeolite particles 43kg; pearl expanded rock powder 6kg; clay 12kg; dolomite powder 12kg.

[0062] Among them, the particle size of steel slag, expanded pearlite and dolomite is less than 0.15mm, specifically about 0.14mm; the content of montmorillonite in expanded pearlite is about 83%; the clay is clean clay, free of organic matter, humus and other impurities. It is required that after the pearl expanded rock is fired, the volume expansion is about 11 times.

[0063] Its preparation method comprises the following steps:

[0064] S1, crushing: steel slag, pearl expanded rock and dolomite are crushed by a crusher respectively, and after passing through a 100-mesh sieve, steel slag powder, pearl expanded rock powder and dolomite powder are obtained; the zeolit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com