Leather sewage emission reduction treatment method

A treatment method and technology for leather sewage, applied in water/sewage treatment, biological water/sewage treatment, light water/sewage treatment, etc., can solve problems such as water pollution, low efficiency, environmental and human hazards, and improve pollution control Efficiency, lower production costs, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

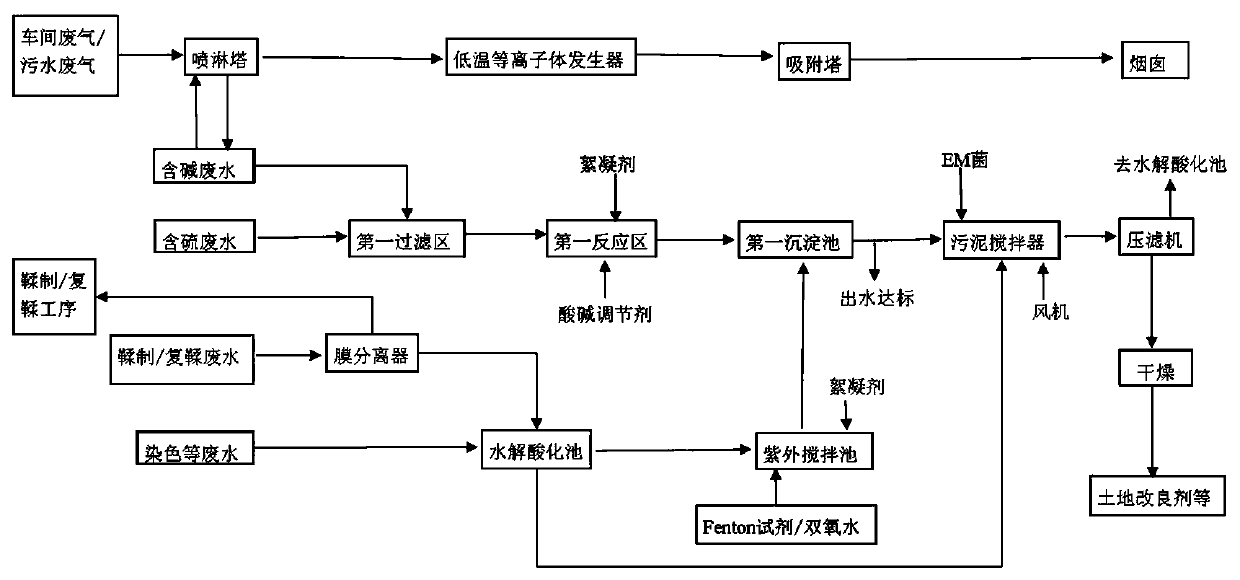

[0028] An environment-friendly method for reducing the discharge of leather sewage, the technological process is as follows figure 1 ,Specific steps are as follows:

[0029] 1) Send the collected workshop waste gas and / or the waste gas produced by the sewage treatment process into the spray tower, and spray it with the alkali-containing wastewater from the leather preparation process to remove the water-soluble acid gas and solid particles in the waste gas, and then the waste gas The volatile organic components in the waste gas are degraded by the dielectric barrier discharge low-temperature plasma generator, and finally discharged from the chimney after being adsorbed and purified by the adsorption tower. After testing, the removal rate of pollutant components in the exhausted flue gas reaches 99%, which meets the national environmental protection requirements. Require;

[0030] 2) The alkali-containing wastewater and sulfur-containing wastewater passing through the spray to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com