Nano-controlled-release pesticide taking polyethylene wax as coating matrix and preparation method thereof

A polyethylene wax and controlled-release pesticide technology, applied in the field of pesticides, can solve the problems of complex preparation process, poor stability, low drug loading, etc., and achieve the effects of simple preparation process, good anti-oxidation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

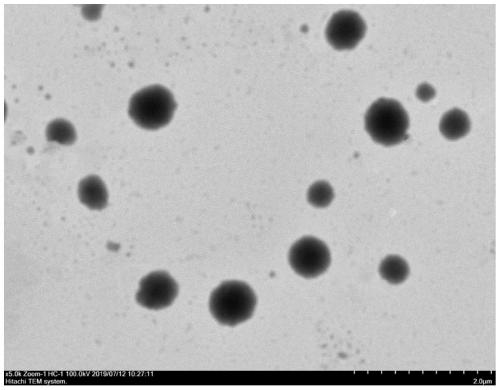

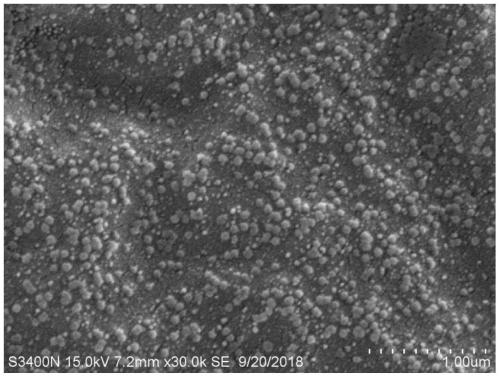

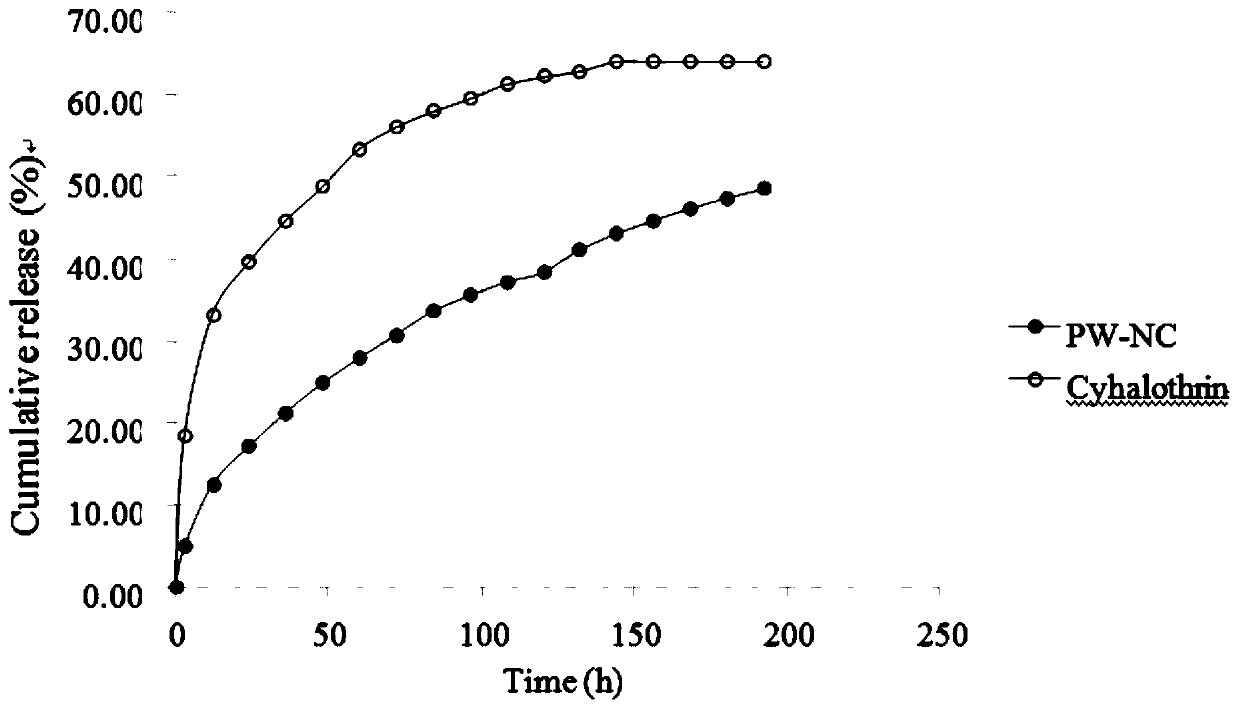

[0042] Example 1 Preparation of 2.5% lambda-cyhalothrin with polyethylene wax as a nano-controlled release pesticide formulation wrapped in matrix

[0043] (1) Weigh 1.5Kg Siben-40 emulsifier and add it to 62L deionized water, stir and dissolve fully to obtain an aqueous solution containing surfactant;

[0044] (2) Add 1.2Kg of polyethylene wax to 31L of butyl acetate, then stir at 60-90°C until the polyethylene wax dissolves, then add 2.8Kg of cyhalothrin, and continue heating at 60-90°C Stir to dissolve to obtain a mixed solution;

[0045] (3) keep the temperature of the mixed solution in step (2) constant, and quickly add it to the surfactant aqueous solution in step (1) under high-speed stirring, and continue to stir at a high speed to obtain a suspoemulsion;

[0046] (4) further ultrasonically dispersing the suspoemulsion described in step (3) at a low temperature of 0-10° C. to obtain a nano-suspoemulsion;

[0047] (5) add 1.7Kg dispersant xanthan gum in the nanosuspen...

Embodiment 2

[0048] Example 2 Preparation of 3.3% Abamectin Nano-controlled Release Pesticide Preparation Using Polyethylene Wax as a Coating Matrix

[0049] (1) Weigh 2Kg Siben-60 emulsifier and add it to 116L deionized water, after fully stirring and dissolving, an aqueous solution containing surfactant is obtained;

[0050] (2) Add 2Kg of polyethylene wax to 30L of sec-butyl acetate, then stir at 60-90°C until the polyethylene wax dissolves, then add 6.3Kg of abamectin, and continue heating and stirring at 60-90°C Dissolved to obtain a mixed solution;

[0051] (3) keep the temperature of the mixed solution in step (2) constant, and quickly add it to the surfactant aqueous solution in step (1) under high-speed stirring, and continue to stir at a high speed to obtain a suspoemulsion;

[0052] (4) further ultrasonically dispersing the suspoemulsion obtained in step (3) at a low temperature of 0-10° C. to obtain a nano-suspoemulsion;

[0053] (5) add 1.4Kg dispersant 500LQ in the nano-sus...

Embodiment 3

[0054] Example 3 Preparation of 3% chlorantraniliprole nano-controlled release pesticide formulation with polyethylene wax as the encapsulation matrix

[0055] (1) Weigh 3.5Kg Siben-20 emulsifier and add it to 116L deionized water, after fully stirring and dissolving, an aqueous solution containing surfactant is obtained;

[0056] (2) Add 2.0Kg of polyethylene wax to 50L of acetamide, then stir at 60-90°C until the polyethylene wax dissolves, then add 5.6Kg of chlorantraniliprole, and continue heating and stirring at 60-90°C Dissolved to obtain a mixed solution;

[0057] (3) keep the temperature of the mixed solution in step (2) constant, and quickly add it to the surfactant aqueous solution in step (1) under high-speed stirring, and continue to stir at a high speed to obtain a suspoemulsion;

[0058] (4) further ultrasonically dispersing the suspoemulsion obtained in step (3) at a low temperature of 0-10° C. to obtain a nano-suspoemulsion;

[0059] (5) add 1.5Kg dispersant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com