A kind of pesticide sustained-release microcapsule and preparation method thereof

A technology for slow-release microcapsules and pesticides, which is applied in botanical equipment and methods, animal repellents, biocides, etc., can solve problems such as inability to prepare microcapsules, and achieves improved encapsulation effect, easy degradation, and easy use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

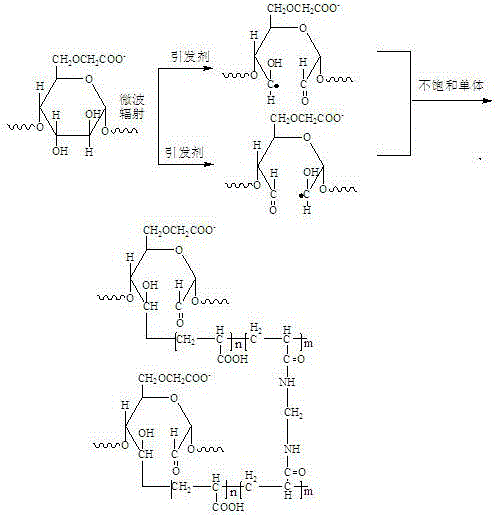

Method used

Image

Examples

Embodiment 1

[0040] (1) Weigh 5g of CMC and dissolve it in 100mL of deionized water, stir to fully dissolve.

[0041] (2) Dissolve 10g of chlorpyrifos in 10g of benzene to obtain a 50% pesticide solution, and then mix it with 30g of methyl methacrylate, 20g of butyl acrylate, 10g of methacrylic acid, 5g of ethylene glycol dimethacrylate and azo After 0.3 g of diisobutyronitrile is mixed evenly, it is added into the CMC solution under the action of high-speed shear force, and is fully dispersed to form an emulsion.

[0042] (3) In a 250ml four-neck bottle equipped with a thermometer, a stirring device and a condenser, add 30mL of emulsion and raise the temperature. After the temperature in the bottle rises to 80°C, apply microwave radiation for 1.5h, and the microwave energy density is 0.05W / cm 2 , and start to drop the mixed emulsion of remaining methyl methacrylate 60g, butyl acrylate 50g, methacrylic acid 20g and azobisisobutyronitrile 0.7g, dropwise in 1.5 hours. Then add 12 g of ethyl...

Embodiment 2

[0045] (1) Weigh 10g of CMC and dissolve it in 100mL of deionized water, stir to fully dissolve.

[0046] (2) Dissolve 5g of abamectin pesticide in 45g of toluene to obtain a 10% pesticide solution, and then mix it with 15g of methyl methacrylate, 18g of butyl acrylate, 2g of ethylene glycol diacrylate and 1.5g of azobisiso After the valeronitrile is mixed evenly, it is added into the CMC solution under the action of high-speed shear force, and is fully dispersed to form an emulsion.

[0047] (3) In a 250ml four-necked bottle equipped with a thermometer, a stirring device and a condenser, add 30mL of emulsion and raise the temperature. After the temperature in the bottle rises to 70°C, apply microwave radiation for 2.5h, and the microwave energy density is 0.03W / cm 2 , and began to drop the remaining mixed emulsion of methyl methacrylate 75g, butyl acrylate 85g and azobisisovaleronitrile 0.1g, and finished dropping within 2 hours. Then add 5 g of ethylene glycol diacrylate, con...

Embodiment 3

[0050] (1) Weigh 15g of CMC and dissolve it in 100mL of deionized water, stir to fully dissolve.

[0051] (2) Dissolve 9 g of pyrethroid pesticides in 21 g of ethyl acetate to obtain a 30% pesticide solution, and then mix them evenly with 20 g of methyl methacrylate, 3 g of divinylbenzene and 0.15 g of benzoyl peroxide. Add it into the CMC solution under the action of high-speed shear force, and fully disperse to form an emulsion.

[0052] (3) In a 250ml four-neck bottle equipped with a thermometer, a stirring device and a condenser, add 30mL of emulsion and raise the temperature. After the temperature in the bottle rises to 50°C, apply microwave radiation for 0.5h, and the microwave energy density is 0.05W / cm 2 , and began to drop the remaining mixed emulsion of methyl methacrylate 70g and benzoyl peroxide 0.6g, and finished dropping within 0.5 hours. Then add 7g of divinylbenzene, continue to keep warm for 4 hours, then cool down, filter and dry to obtain the CMC composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com