Preparation method of high performance magnesium-based composite material component

A composite component and high-performance technology, applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as difficult control, complicated preparation process, easy agglomeration, etc., and achieve no shrinkage cavity, advanced technology, and accurate data informative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

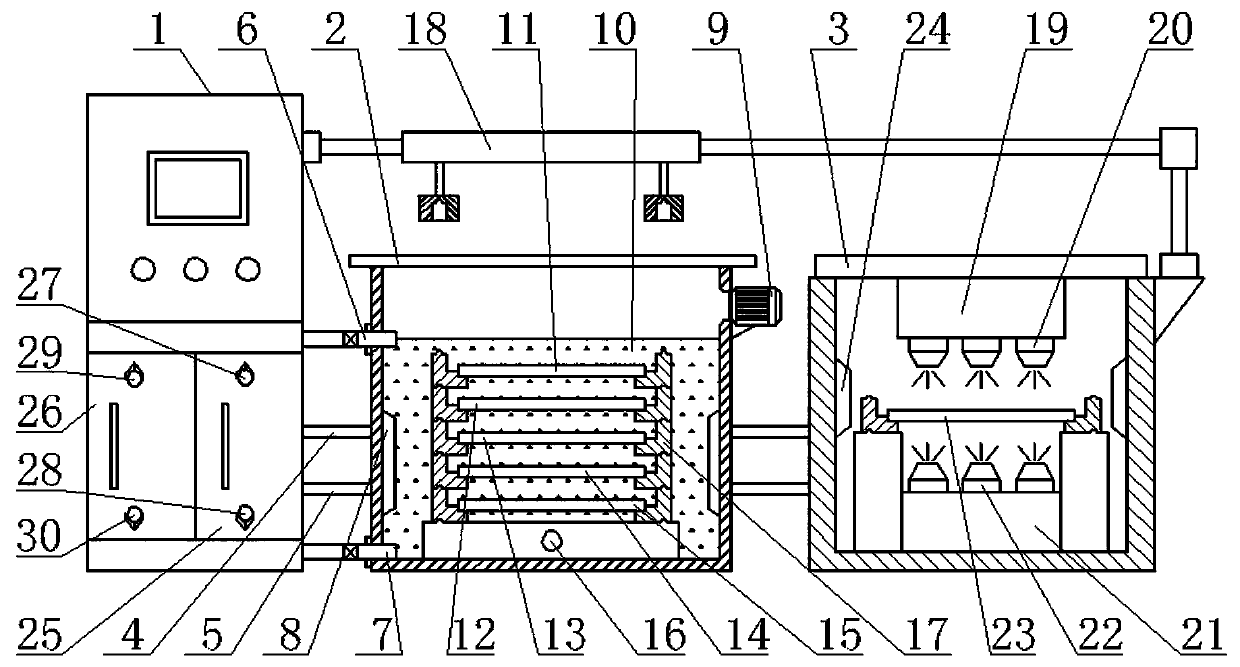

[0072] figure 1 As shown, it is the surface treatment of the magnesium alloy plate and the state diagram of carboxylated graphene sprayed on the surface of the magnesium alloy plate after surface treatment; the whole set of equipment includes the main control cabinet 1, the surface treatment room 2, and the surface spraying room 3;

[0073] The main control cabinet 1 controls the working state of the surface treatment chamber 2 through the first cable 4 and the second cable 5 on the one hand, and controls the working state of the surface spraying chamber 3 through the first cable 4 and the second cable 5 on the other hand;

[0074] A polyvinyl alcohol liquid storage tank 25 and a deionized water liquid storage tank 26 are respectively provided under the main control cabinet 1; a polyvinyl alcohol liquid inlet valve 27, a polyvinyl alcohol discharge valve, Liquid valve 28; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com