Improved method for acetylation of alkali lignin

A technology of alkali lignin and acetylation, applied in the improvement field of alkali lignin acetylation, can solve the problems of high price, difficult biodegradation, high toxicity of pyridine, etc., and achieve the effect of cost saving, simple process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

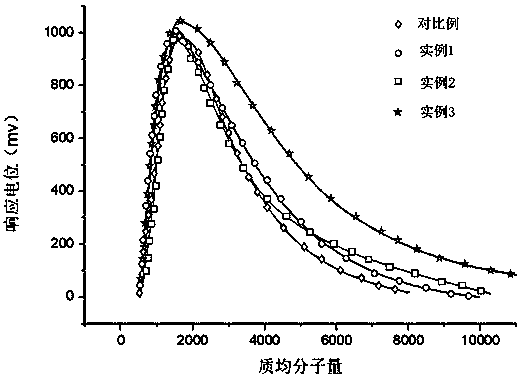

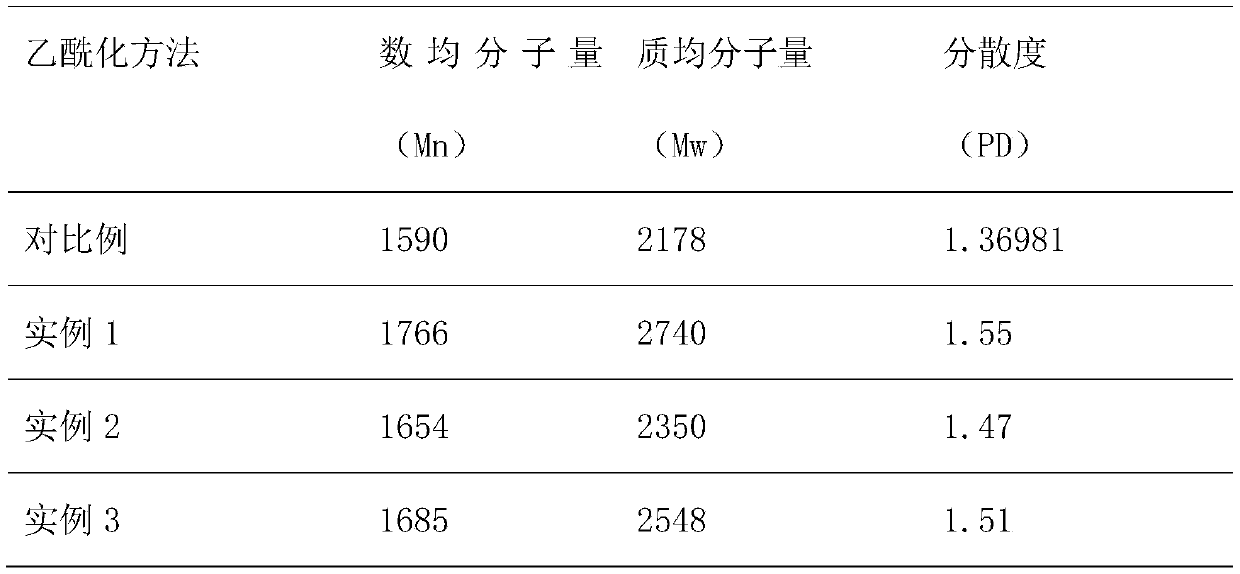

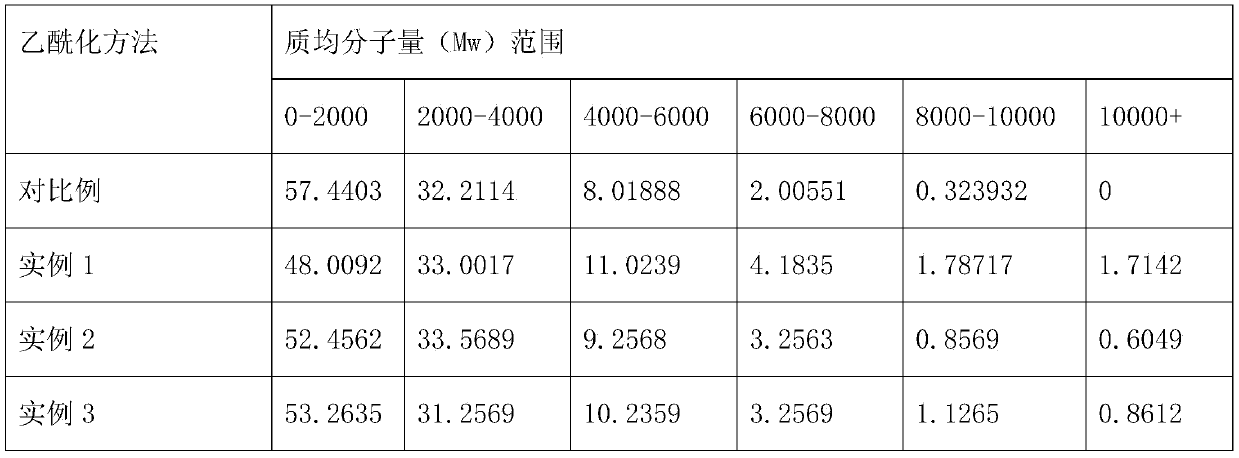

[0034] Carry out the acetylation of alkali lignin with the improved method of a kind of alkali lignin acetylation described in the present invention, the process is as follows: a, lactic acid: choline chloride 1: 1 (molar ratio) is mixed in the beaker, 30 ℃ water bath heating and stirring (stirring speed 200r / min) for 1 hour to prepare a deep eutectic solvent (DES), and put it into a reagent bottle for storage at room temperature. b. Dissolve 100 mg of purified alkali lignin in 8 ml of DES / acetic anhydride (2:1V:V) mixed solution prepared in step a. At the same time, nitrogen gas is passed into the container and sealed. Stir at room temperature for 12 hours under dark conditions. , stop the reaction, wherein the purification conditions of alkali lignin are: first dissolve the crude alkali lignin in acetic acid / water (6:1V:V) solution, then centrifuge to remove the precipitate, obtain an extract, and then add it to the extract Add water to make the alkali lignin precipitate, ta...

Embodiment 2

[0036]Carry out the acetylation of alkali lignin with the improved method of a kind of alkali lignin acetylation of the present invention, the process is as follows: a, lactic acid: choline chloride 2: 1 (molar ratio) is mixed in the beaker, 60 Heat and stir in a water bath at ℃ (stirring speed 300r / min) until the solution is clear and transparent to prepare a deep eutectic solvent (DES), and store it in a reagent bottle at room temperature. b. Dissolve 200 mg of purified alkali lignin in 8 ml of the DES / acetic anhydride (1:1V:V) mixed solution prepared in step a. At the same time, nitrogen gas is introduced into the container and sealed. Stir at room temperature for 24 hours under dark conditions. , stop the reaction, wherein the purification conditions of alkali lignin are: first dissolve the crude alkali lignin in acetic acid / water (9:1V:V) solution, then centrifuge to remove the precipitate, obtain an extract, and then add it to the extract Add water to make the alkali lig...

Embodiment 3

[0038] Carry out the acetylation of alkali lignin with the improved method of a kind of alkali lignin acetylation of the present invention, the process is as follows: a, lactic acid: choline chloride 3: 1 (molar ratio) is mixed in the beaker, 80 Heat and stir in a water bath at ℃ (stirring speed 500r / min) until the solution is clear and transparent to prepare a deep eutectic solvent (DES), and store it in a reagent bottle at room temperature. b. Take 300 mg of purified alkali lignin and dissolve it in 8 ml of DES / acetic anhydride (1:2V:V) mixed solution prepared in step a. At the same time, nitrogen gas is passed into the container and sealed. Stir at room temperature for 36 hours under dark conditions. , stop the reaction, wherein the purification conditions of alkali lignin are: first dissolve the crude alkali lignin in acetic acid / water (10:1V:V) solution, then centrifuge to remove the precipitate, obtain an extract, and then add it to the extract Add water to make the alka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com