A kind of high damping fiber reinforced resin matrix composite material and its preparation method

A fiber reinforced resin and composite material technology, applied in the field of composite materials, can solve the problems of weakening the mechanical bonding effect of the fiber/resin interface, the strength of the composite material not meeting the requirements for use, and hindering the flow of fuel, so as to inhibit crack propagation and improve the mold. Quantity and strength, the effect of improving the interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned high-damping fiber-reinforced resin-based composite material includes the following steps:

[0033] S1 Selectively remove the sizing agent on the fiber according to the requirements and conditions of the interface modification process;

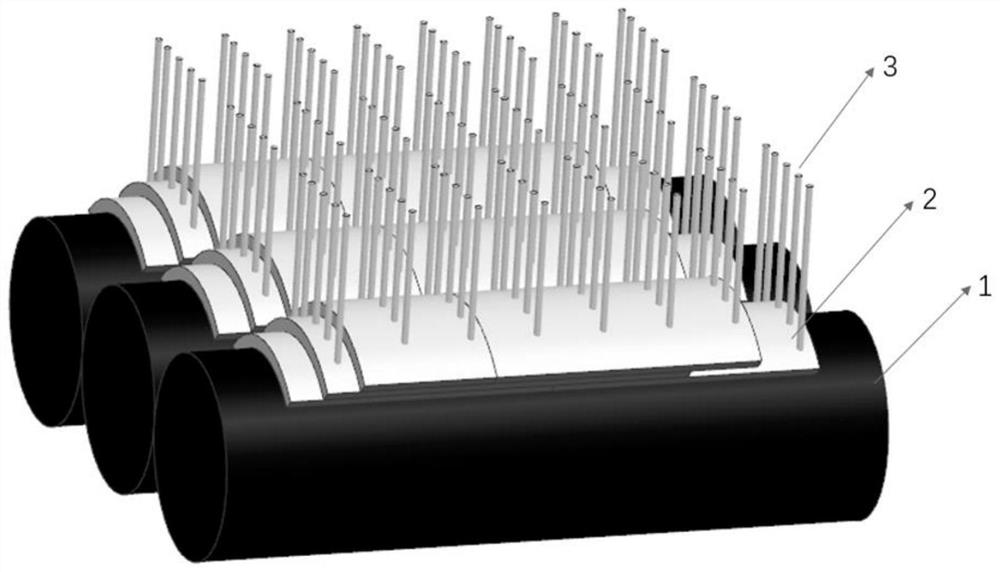

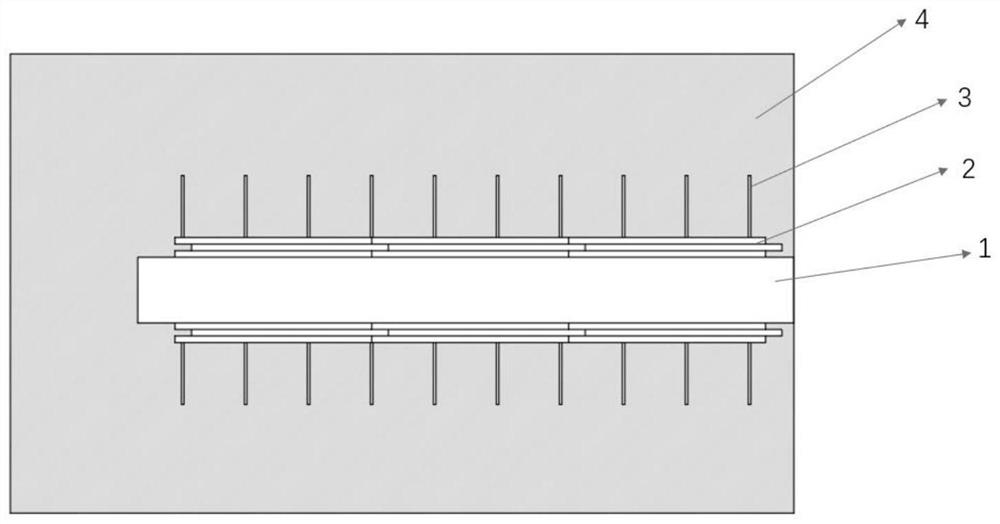

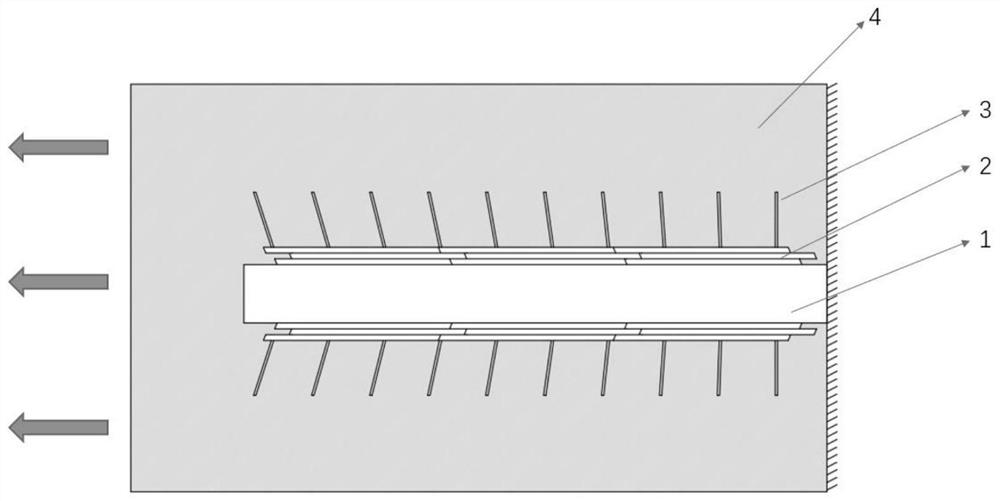

[0034] S2 deposits two-dimensional nanomaterials on the fiber surface, and then grafts one-dimensional nanomaterials on the two-dimensional nanomaterials to form three-dimensional nanostructures;

[0035] S3 blends fibers with a three-dimensional nanostructure on the surface with a resin matrix to obtain a fiber-reinforced resin-based composite material.

[0036] Further, in said S1, the sizing agent on the fiber is removed by soaking in acetone or baking at high temperature;

[0037] Further, in S2, two-dimensional nanomaterials are deposited on the surface of the fiber by electrophoretic deposition, chemical vapor deposition or chemical grafting.

[0038] Further, in S2, the one-dimensio...

specific Embodiment

[0041]1) The fiber surface sizing agent can be selectively removed according to the process requirements

[0042] Choose the acetone immersion method. Soak carbon fiber T300 woven cloth in acetone solution, take it out after 12 hours of treatment, observe the surface of carbon fiber with SEM, if the surface is smooth and free of impurities, it meets the requirements.

[0043] 2) Deposition of two-dimensional nanomaterials on the fiber surface

[0044] Graphene is selected as the two-dimensional material, and electrophoretic deposition is selected as the deposition method. Get graphene oxide and distilled water configuration mass solubility to be the graphene oxide aqueous solution of 0.25g / L, the carbon fiber cloth that step 1) obtains is used as the negative electrode of electrophoresis test, is connected with the negative pole of power supply, and copper sheet is used as anode, connects with the positive pole of power supply Connected, both are immersed in graphene oxide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com