Zn-RE series zinc alloy as well as preparation method and application thereof

A zinc alloy and alloying element technology, applied in the field of Zn-RE series zinc alloy and its preparation, can solve the problems of difficult to meet clinical application, difficult to meet clinical needs, low alloy plasticity, etc., and achieve good biocompatibility and mechanical properties The effect of improving and reducing alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

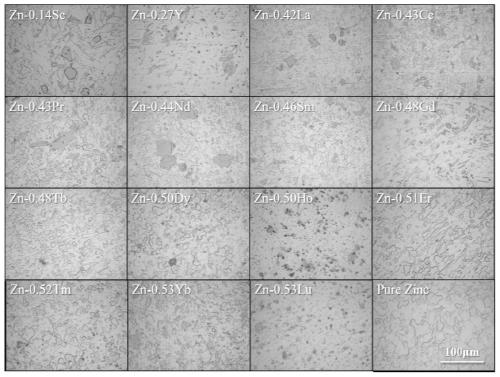

Image

Examples

Embodiment 1

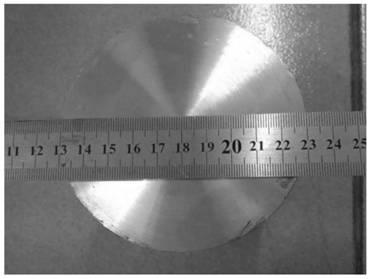

[0048] Embodiment 1, preparation cast state Zn-0.43Pr zinc alloy

[0049] Using intermediate frequency furnace for non-vacuum melting, corundum crucible, using chaff covering melting, in CO 2 and SF 6 Under the protection of the atmosphere, the Zn-0.56Pr master alloy is prepared according to the ratio of the mass percentage of Pr to 0.56%, and the balance is zinc, and the calculated quality of the Zn-0.56Pr master alloy is mixed with pure zinc and thrown into the intermediate frequency furnace without vacuum Melting, the temperature is 680 ℃, after cooling, the Zn-0.43Pr ingot is obtained, the test is qualified, and the wagon.

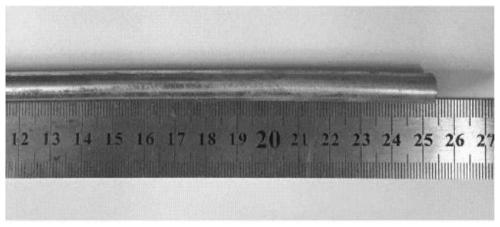

Embodiment 2

[0050] Embodiment 2, preparation cast state Zn-0.48Gd zinc alloy

[0051] Using intermediate frequency furnace for non-vacuum melting, graphite crucible, using salt covering melting, in CO 2 and SF 6 Under the protection of the atmosphere, according to the ratio of Gd mass percentage of 0.48% and the balance of zinc, the raw materials are put into the intermediate frequency furnace for melting, the melting temperature is 650°C, and the Zn-0.48Gd ingot is obtained after cooling, and the test is qualified ,wagon.

Embodiment 3

[0052] Embodiment 3, preparation cast state Zn-0.51Er zinc alloy

[0053] Use intermediate frequency furnace for non-vacuum melting, graphite crucible, cover melting with chaff, in CO 2 and SF 6 Under the protection of the atmosphere, according to the ratio of the mass percentage of Er to 0.51% and the balance of zinc, the raw materials are put into an intermediate frequency furnace for melting, and the melting temperature is 700 ° C. After cooling, a Zn-0.51Er ingot is obtained, which is qualified for inspection ,wagon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com