Multi-component composite silica negative electrode material for lithium ion battery and preparation method thereof

A lithium-ion battery, multi-component composite technology, used in battery electrodes, electrical components, secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

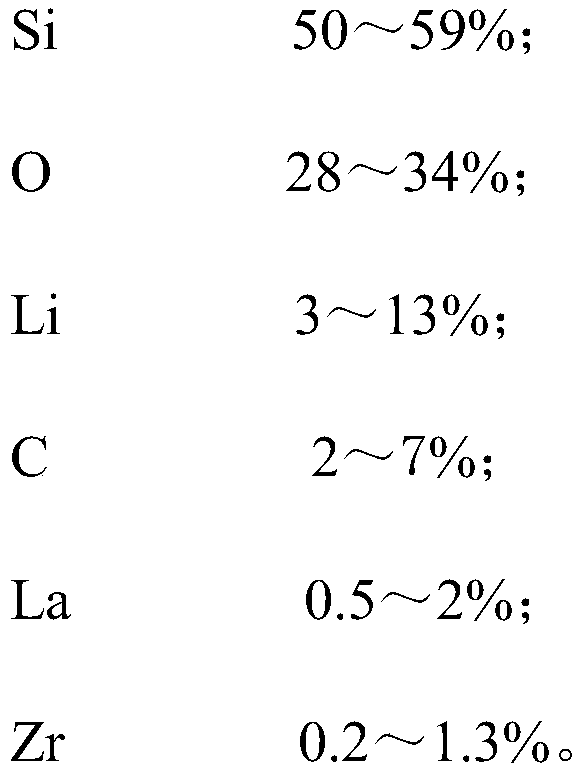

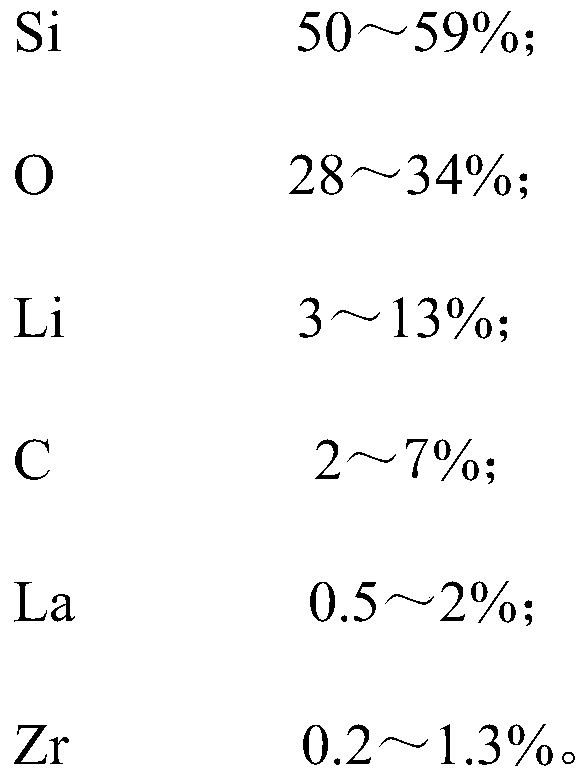

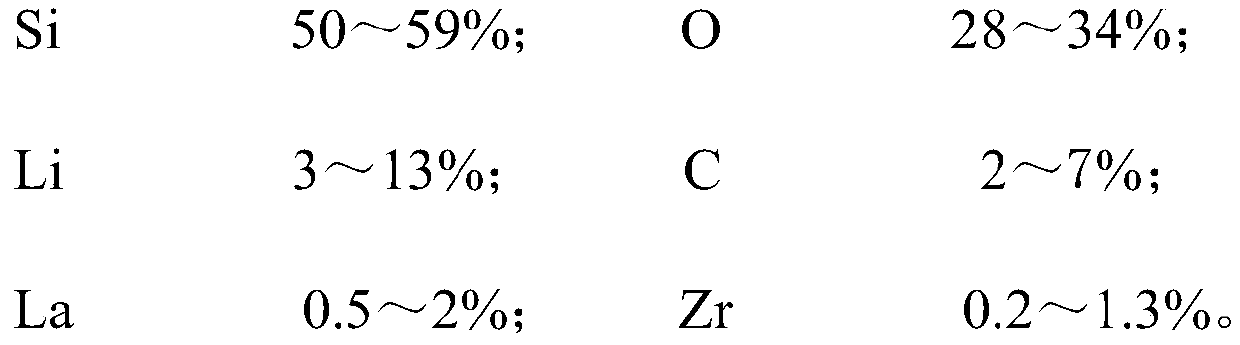

[0032] A preparation method of a multi-element composite silicon-oxygen anode material for lithium ion batteries, the preparation method specifically includes the following steps:

[0033] The first step is to first use silicon oxide powder with a carbon coating on the surface, mix it with the lithium source powder uniformly under the protection of a non-oxidizing atmosphere, and then heat the mixture to 350-750°C and heat it for 2-24 hours. After cooling to room temperature, a basic powder is obtained; the silicon oxide powder body with a carbon coating layer on the surface is a composite powder obtained by co-deposition of silicon oxide and carbon or a silicon oxide powder body is made and then passed through a carbon coating Coated powder; the carbon source for the coated carbon can be any one of sucrose, glucose, citric acid, pitch, furfuryl alcohol resin, phenolic resin, polyethylene, polystyrene, polypropylene, methane, propane, and acetylene Or a combination of two or more...

specific Embodiment

[0045] The invention adopts ICP-AES as the analysis means of material composition, and adopts the high-frequency induction carbon-sulfur analyzer as the analysis means of carbon content. Using the materials obtained in the examples and comparative examples, coin-type secondary batteries were produced to evaluate the usability of the materials.

[0046] First, prepare a silicon oxide powder with a carbon coating layer. Take commercially available silica powder with silicon-oxygen atom molar ratio of 1:1, particle size D50 of 6 microns, high-temperature petroleum pitch powder as carbon coating agent, and mechanically mix the two powders with a high-mixer in an appropriate ratio Then, put it into a vacuum heating furnace and heat it to 800 degrees Celsius for 2 hours, cool to room temperature, and then be broken up and sieved for use. Using this method, three basic powders with carbon content of 2.5%, 5.2%, and 7.6% were obtained.

Embodiment 1

[0048] Take 100g of the basic powder with a carbon content of 2.5% and 10g of Li3N powder, mix them evenly in an argon protective box; then place them in an argon atmosphere for heat treatment at 500 degrees for 12h, and cool to room temperature naturally. Add 0.2g of lithium hydroxide, 0.7g of lanthanum hydroxide, and 0.9g of zirconium acetate to 100g of the above powders, and disperse them at a high speed to uniformly fuse them; then place them in an argon atmosphere for heat treatment at 600°C for 1h, and cool to room temperature naturally. Break up and screen to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com