Brassinolide soluble granules and preparation method thereof

A brassinolide soluble technology, applied in the field of brassinolide soluble granules and its preparation, can solve the problem of low solubility, achieve good solubility, safe and convenient packaging, storage and transportation, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Put 0.316kg of diethyl ether, 0.032kg of brassinolide technical sieve with 80 mesh and 95% fineness, 0.15kg of alkylphenol polyoxyethylene ether, and 9kg of sodium lauryl sulfate into a 2000ml reaction bottle, stir to dissolve After about 15 minutes, release it for coating.

[0058] Add 298.2 kg of crushed and sieved 20-60 mesh potassium dihydrogen phosphate particles into a horizontal mixer with a volume of 2000 L, start stirring, and slowly spray the above-mentioned brassinolide solution into it, finish spraying in about 2 minutes, and mix after spraying Close the machine and continue to work for 10 minutes to discharge, which is 0.01% brassinolide soluble granules.

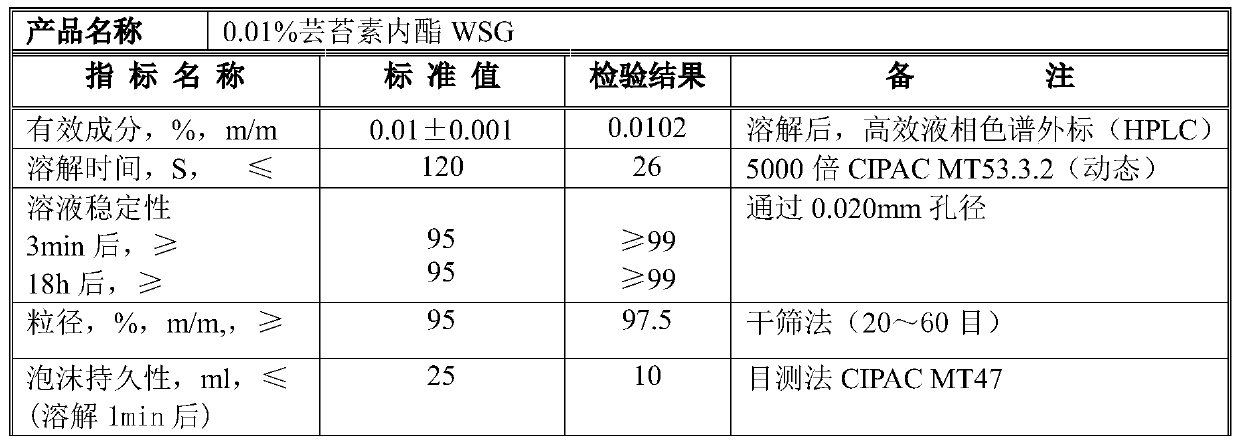

[0059] The 0.01% brassinolide soluble granules (ie 0.01% WSG) obtained by the above-mentioned preparation process, the particles are spherical irregular particles, and the specific technical indicators of this embodiment after testing are as shown in Table 1:

[0060] Table 1

[0061]

[0062]

...

Embodiment 2

[0065] 3.158kg of ethanol, 0.316kg of brassinolide technical sieved with a fineness of 80 mesh and 95%, 1kg of PO-EO block polyether (OP20), 0.5kg of fast penetrating agent T, and 1.5 kg of sodium lauryl sulfate kg was put into a 10l glass reactor, stirred and dissolved, released for coating in about 15 minutes.

[0066] Add 295.2 kg of crushed and sieved 20-60 mesh urea granules into a horizontal mixer with a volume of 2000 L, start stirring, slowly spray the above-mentioned brassinolide solution into the mixer, and at the same time, blow 65 ± 5 ° C into the mixer The hot air is sprayed in about 10 minutes, and the mixer continues to work for 10 minutes to discharge the material, which is 0.1% brassinolide soluble granules.

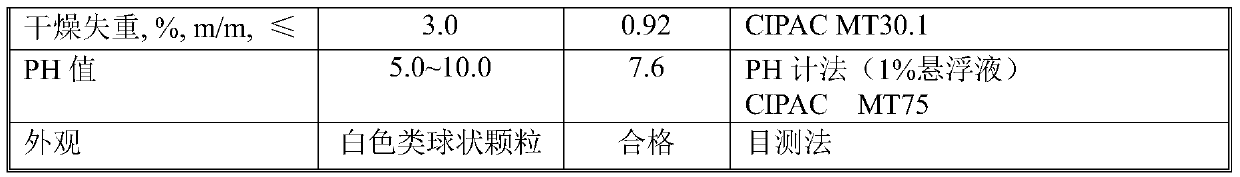

[0067] The 0.1% brassinolide soluble granules (ie 0.1% WSG) obtained by the above-mentioned preparation process, the particles are spherical irregular particles, and the specific technical indicators of this embodiment after testing are as shown in Table...

Embodiment 3

[0072] Put 15.8kg of methanol, 1.579kg of brassinolide crude drug 1.579kg of sieved fineness 80 mesh 95%, fast penetrating agent T7.5kg, sodium lignosulfonate 7.5kg into a 50l reactor, stir and dissolve after about 15 Released in minutes to be used for coating.

[0073] Add 281.9kg of crushed and sieved 20-60 mesh lactose granules into a horizontal mixer with a capacity of 2000L, start stirring, and slowly spray the above-mentioned brassinolide solution in, and finish spraying in about 30 minutes. After spraying, the mixer continues After working for 15 minutes, the material is 0.5% brassinolide soluble granules.

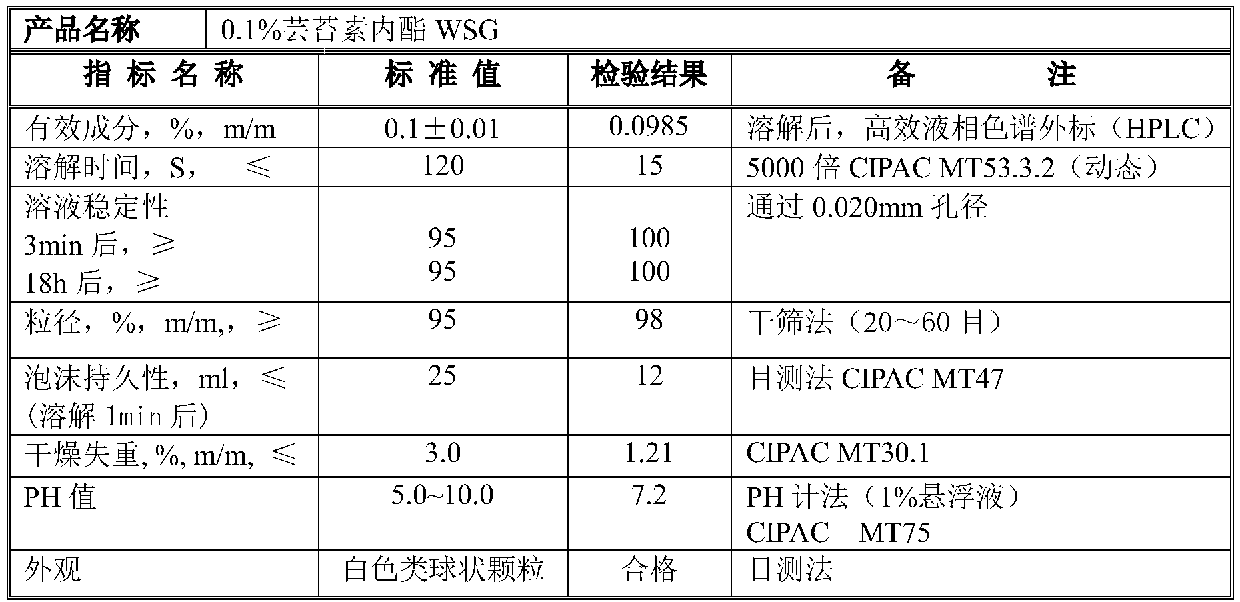

[0074] The 0.5% brassinolide soluble granules (ie 0.5% WSG) obtained by the above-mentioned preparation process, the granules are spherical irregular granules, and the specific technical indicators of this embodiment after testing are shown in Table 3

[0075] Shown:

[0076] table 3

[0077]

[0078] As can be seen from the detection data in the table above, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com