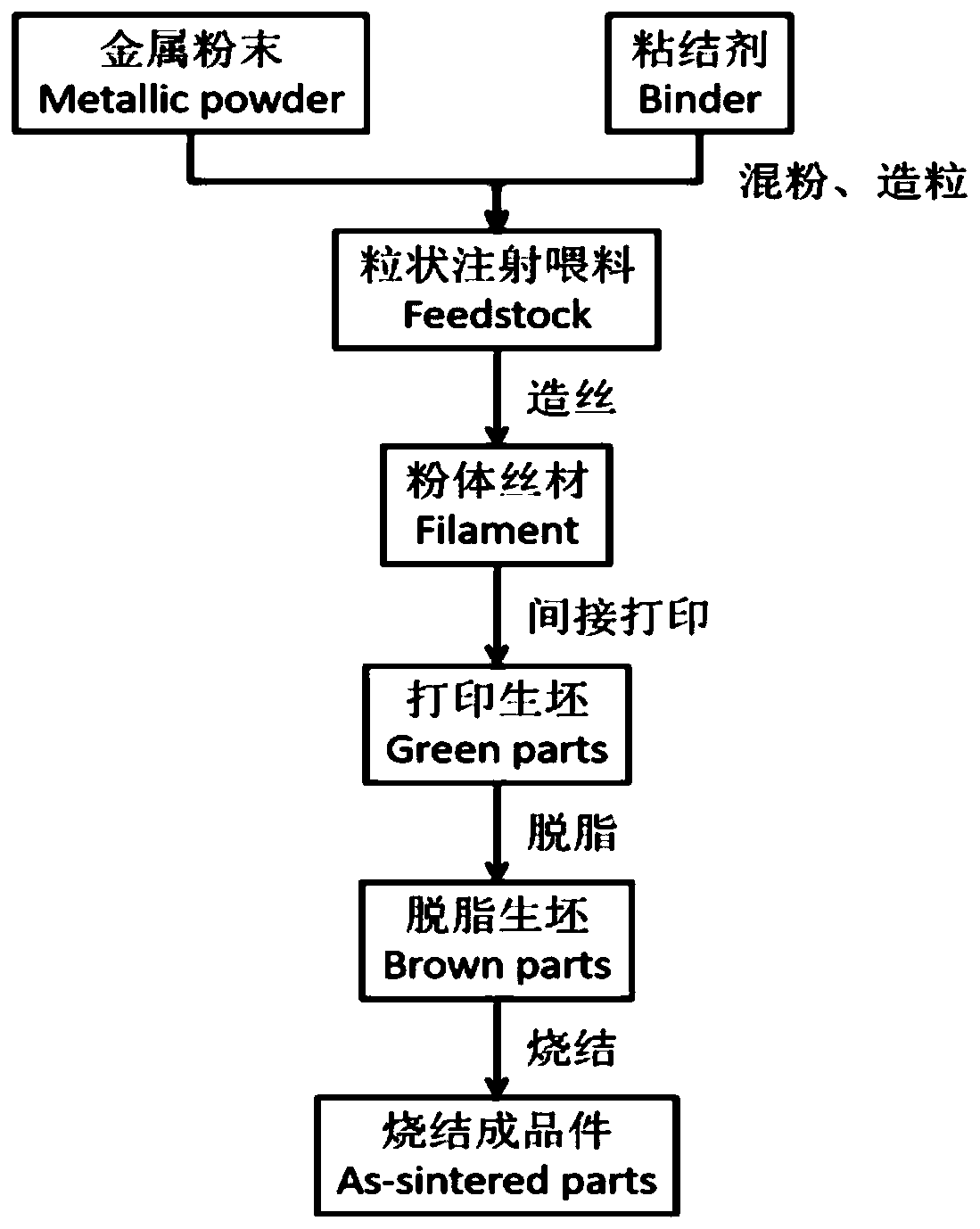

Low-cost titanium alloy indirect additive manufacturing method

A technology of additive manufacturing and titanium alloy, which is applied in the field of additive manufacturing, can solve the problems of difficult to obtain titanium alloy parts with ideal mechanical properties, irregular shape, and difficulty in forming, so as to achieve good quality of printed products, low cost of printing equipment, and improved Yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the method of indirectly printing titanium alloy parts with spherical titanium powder mixed with hydrogenated dehydrogenated titanium powder and added with rare earth yttrium powder:

[0031] Put the spherical pure titanium powder accounting for 50% of the total weight of the mixed powder, the hydrogenated dehydrogenation titanium powder accounting for 49.8% of the total weight of the mixed powder, the yttrium element powder accounting for 0.2% of the total weight of the mixed powder and the binder accounting for 25% of the total volume of the feed. Put it into a Sigma powder mixer, stir and mix for 2 hours at a temperature of 110°C, and the binder is made of the following raw materials in parts by weight: 45 parts of polyethylene polymer, 45 parts of paraffin, and 4 parts of stearic acid; then use granulation The machine prepares a granular feed with a diameter of less than 5mm; using an injection machine, manufactures an indirect additive manufacturing wi...

Embodiment 2

[0032] Embodiment 2, the method of indirectly printing titanium alloy parts with low-cost hydrogenated dehydrogenation titanium alloy powder mixed with other metal powders:

[0033] Accounting for 94.5% of the total weight of the mixed powder TC4 (Ti-6Al-4V) titanium alloy powder, conventional 316L stainless steel powder accounting for 5% of the total weight of the mixed powder and 0.5% of the yttrium element powder and accounting for the total weight of the mixed powder The binder with 36% of the total volume of the material was put into a Sigma powder mixer, and mixed and stirred for 4 hours at a temperature of 150°C. The binder was made of the following raw materials in parts by weight: 47 parts of polyethylene polymer, 48 parts of paraffin, 5 parts of stearic acid; the use of 316L stainless steel powder is beneficial to the sintering and densification of titanium alloy parts, and it is a sintering auxiliary agent. Then use a granulator to prepare granular feed with a diame...

Embodiment 3

[0034] Embodiment 3, the method of indirectly printing titanium alloy parts with low-cost hydrogenated dehydrogenation titanium alloy powder mixed with spherical titanium alloy powder:

[0035]Accounting for 83.2% of the total weight of the mixed powder TC4 (Ti-6Al-4V) titanium alloy powder, accounting for 15% of the total weight of the mixed powder atomized spherical Ti-6Al-4V titanium alloy powder, accounting for 1.8% of the total weight of the mixed powder Put the yttrium element powder and the binder accounting for 45% of the total volume of the feed into the Sigma powder mixer, and mix and stir for 6 hours at a temperature of 170 ° C. The binder is made of the following raw materials in parts by weight: polyethylene polymer 55 Parts, 55 parts of paraffin, 5 parts of stearic acid; the use of 15wt.% spherical titanium alloy powder is beneficial to increase the loading of metal powder in granular feed and wire, and promote the sintering and densification of titanium alloy par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com