Preparation method of steel surface in-situ growth zinc-aluminum hydrotalcite film

A zinc-aluminum hydrotalcite, in-situ growth technology, applied in the plating of superimposed layers, liquid chemical plating, coating, etc., can solve the problem of poor heat resistance, uneven dispersion of LDHs powder, weak metal matrix bonding force, etc. problem, to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) According to the mass ratio of 49:49:2, weigh Al powder, Al 2 o 3 and NH 4 Cl, the aluminizing agent is obtained after uniform mixing.

[0046] (2) Cover the bottom of the aluminized tank with aluminizing agent to a thickness of about 5mm, put a Q235 steel sheet of 10mm×10mm×3mm into the aluminizing tank, and then pour the aluminizing agent to cover the surface of the Q235 steel to a thickness of about 5mm.

[0047] (3) Put the aluminized tank into a box furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep it warm for 5 hours; after cooling with the furnace, take out the steel sample and clean the residual aluminizing agent with ethanol, and dry it at room temperature Aluminized steel is obtained.

[0048] (4) With n(Zn 2+ ):n(NH 4 NO 3 ) = Zn(NO 3 ) 2 , NH 4 NO 3 Mix the solutions, add 5% ammonia water dropwise to adjust the pH to 6.5, and transfer the above solution into a polytetrafluoro-lined autoclave.

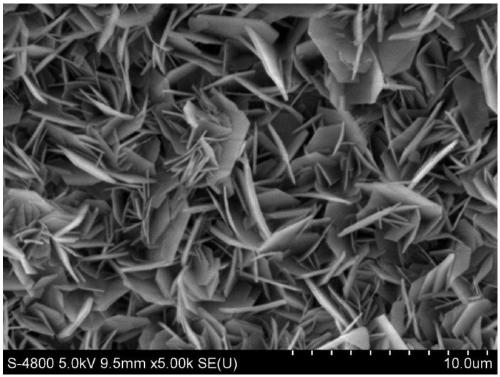

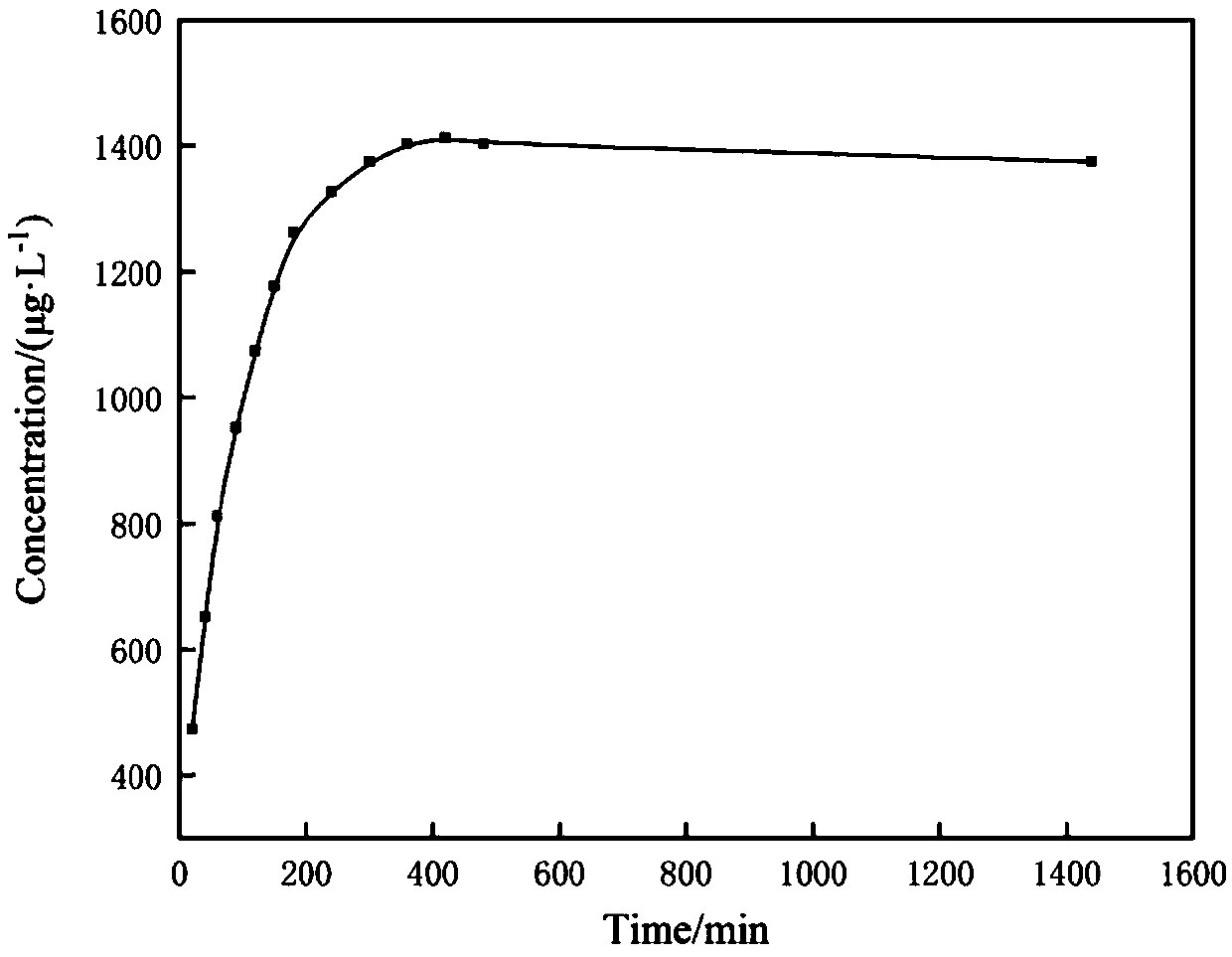

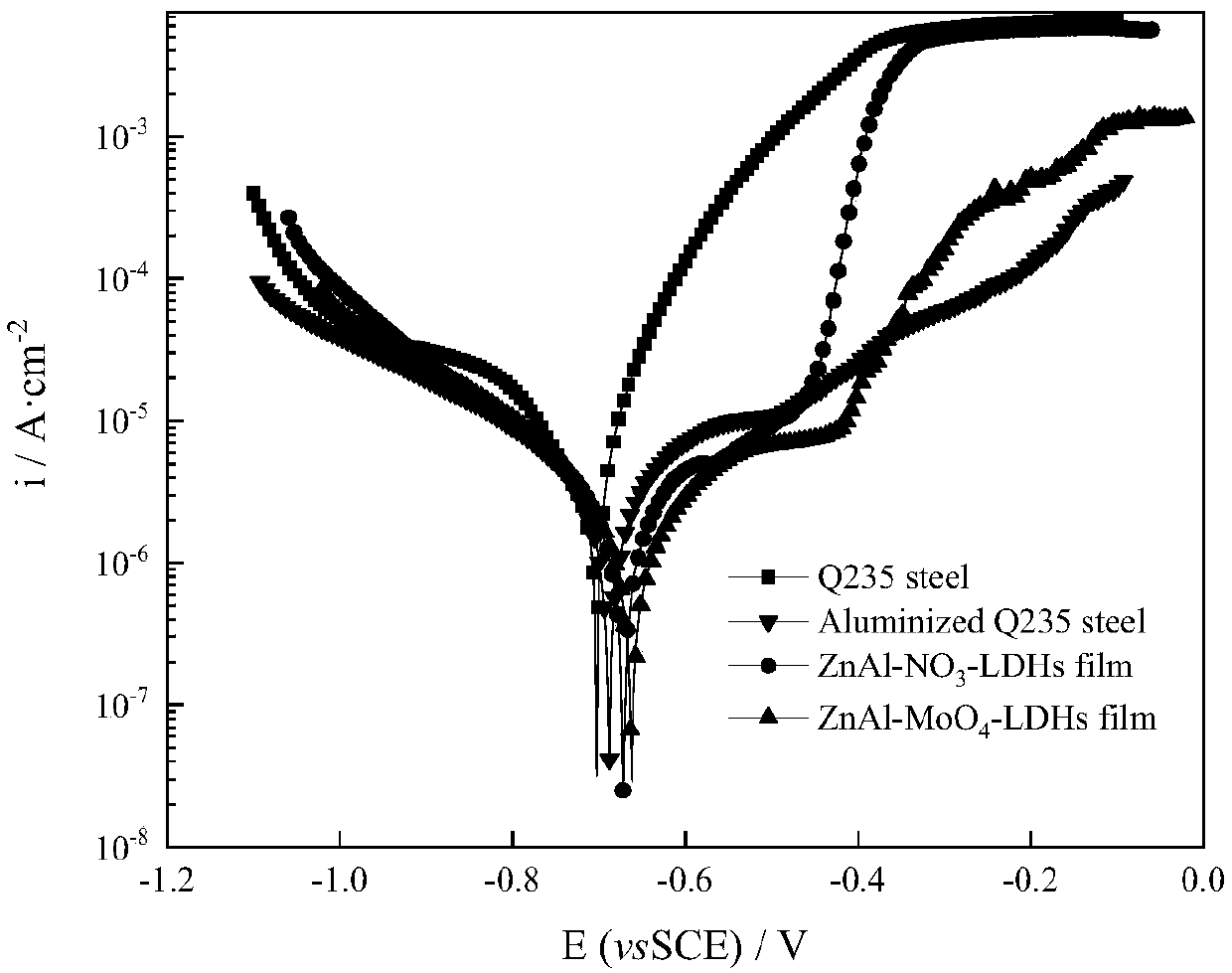

[0049] (5) The aluminized s...

Embodiment 2

[0053] (1) According to the mass ratio of 49:49:2, weigh Al powder, Al 2 o 3 and NH 4 Cl, the aluminizing agent is obtained after uniform mixing.

[0054] (2) Cover the bottom of the aluminized tank with aluminizing agent to a thickness of about 5mm, put a Q235 steel sheet of 10mm×10mm×3mm into the aluminizing tank, and then pour the aluminizing agent to cover the surface of the Q235 steel to a thickness of about 5mm.

[0055] (3) Put the aluminized tank into a box furnace, raise the temperature to 600°C at a rate of 10°C / min, and keep it warm for 4 hours; after cooling with the furnace, take out the steel sample and clean the residual aluminizing agent with ethanol, and dry it at room temperature Aluminized steel is obtained.

[0056] (4) With n(Zn 2+ ):n(NH 4 NO 3 )=1:1 ratio configuration of 0.05mol / L of Zn(NO 3 ) 2 , NH 4 NO 3 Mix the solutions, add 5% ammonia water dropwise to adjust the pH to 7.0, and transfer the above solution into a polytetrafluoro-lined aut...

Embodiment 3

[0061] (1) According to the mass ratio of 49:49:2, weigh Al powder, Al 2 o 3 and NH 4 Cl, the aluminizing agent is obtained after uniform mixing.

[0062](2) Cover the bottom of the aluminized tank with aluminizing agent to a thickness of about 5mm, put a Q235 steel sheet of 10mm×10mm×3mm into the aluminizing tank, and then pour the aluminizing agent to cover the surface of the Q235 steel to a thickness of about 5mm.

[0063] (3) Put the aluminized tank into a box furnace, raise the temperature to 650°C at a rate of 10°C / min, and keep it warm for 3 hours; after cooling with the furnace, take out the steel sample and clean the residual aluminizing agent with ethanol, and dry it at room temperature Aluminized steel is obtained.

[0064] (4) With n(Zn 2+ ):n(NH 4 NO 3 )=1:1 ratio configuration of 0.05mol / L of Zn(NO 3 ) 2 , NH 4 NO 3 Mix the solutions, add 5% ammonia water dropwise to adjust the pH to 8.0, and transfer the above solution into a polytetrafluoro-lined auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com