A kind of cotton/polyamide fabric ink-jet printing pretreatment agent and pretreatment process

A pretreatment agent and inkjet printing technology, applied in fiber treatment, biochemical fiber treatment, plant fiber, etc., can solve problems such as uneven distribution and inability to solve cotton/polyamide fabrics, and achieve simple production process and excellent friction fastness Degree and soaping fastness, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

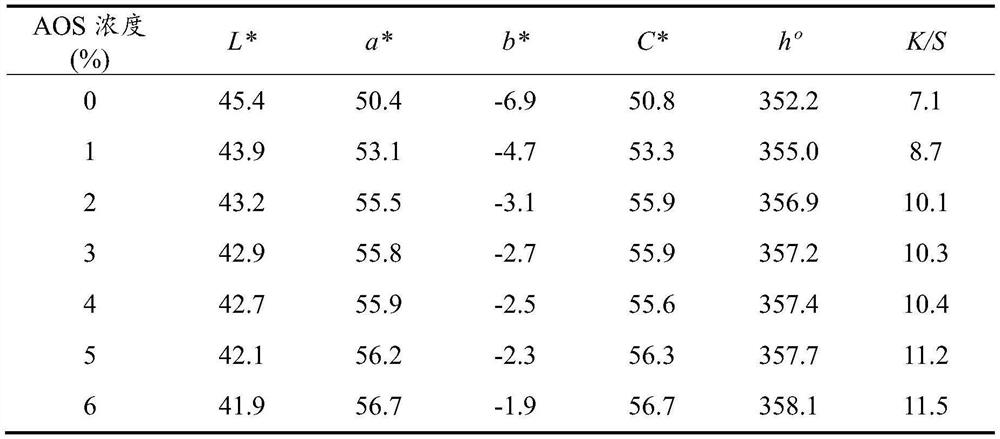

[0041] Prepare 2-tetradecenyl-1-sodium sulfonate with different contents (0~6wt%), sodium alginate 2wt%, sodium bicarbonate 3wt%, ethylene glycol 1wt%, 2-methyl-4-isothiazoline -3-ketone 0.5wt% and m-nitrobenzenesulfonate sodium 0.5wt% pretreatment agent: 3g sodium bicarbonate, 1g ethylene glycol, 0.5g 2-methyl-4-isothiazoline-3-one and 0.5g of sodium m-nitrobenzenesulfonate are completely dissolved in 86-93g of distilled water, and 0-6g of 2-tetradecenyl-1-sodium sulfonate with an active ingredient of 35% is added, and the process is carried out at a speed of 300r / min. Stir, and pour 2g of sodium alginate slowly during the stirring process, stir for 2 hours, and then obtain the pretreatment agent used after it is uniformly dissolved.

[0042] Use the P-B0 horizontal padding machine to pad the prepared pretreatment solution onto the cotton / polyamide fabric to be treated respectively, and the pressure on both sides of the roll is 0.1kg / cm 2 , the roll speed is 12r / min, and the...

Embodiment 2

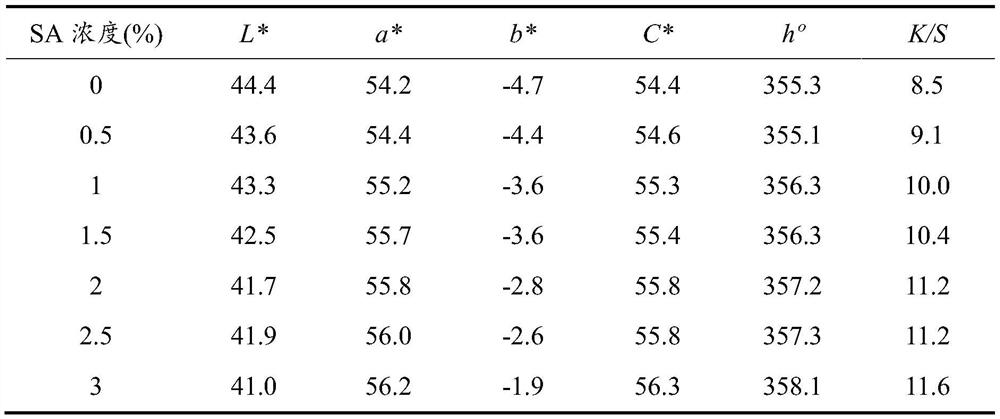

[0053] Prepare sodium alginate with different contents (0-3wt%), 5wt% sodium 2-tetradecenyl-1-sulfonate, 3wt% sodium bicarbonate, 1wt% ethylene glycol, 2-methyl-4-isothiazoline -3-ketone 0.5wt% and m-nitrobenzene sodium sulfonate 0.5wt% pretreatment agent: 3g sodium bicarbonate, 1g ethylene glycol, 0.5g2-methyl-4-isothiazolin-3-ketone and Dissolve 0.5g of sodium m-nitrobenzenesulfonate completely in 87-90g of distilled water, add 5g of AOS solution with an active ingredient of 35%, and stir at a speed of 300r / min. During the stirring process, slowly dissolve 0-3g of sodium alginate Pour slowly, and the pretreatment agent used will be obtained after it is uniformly dissolved.

[0054] Use the P-B0 horizontal padding machine to pad the prepared pretreatment solution onto the cotton / polyamide fabric to be treated respectively, and the pressure on both sides of the roll is 0.1kg / cm 2 , the roll speed is 12r / min, and the liquid carrying rate of the fabric is (75±1)%. The padded f...

Embodiment 3

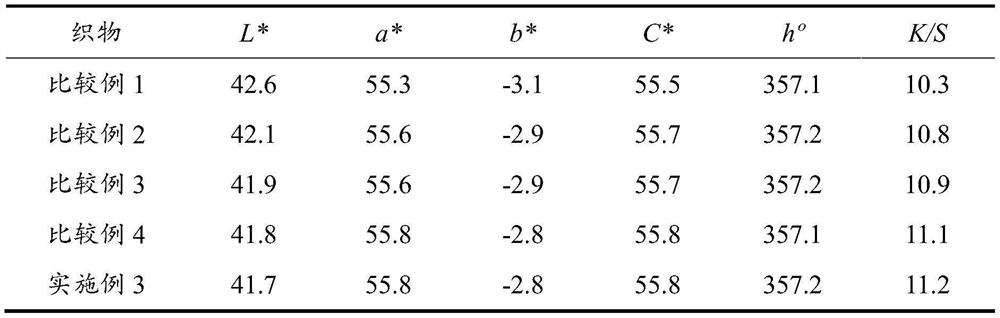

[0061] Prepare sodium alginate 2wt%, 2-tetradecenyl-1-sodium sulfonate 5wt%, sodium bicarbonate 3%, ethylene glycol 1wt%, 2-methyl-4- The pretreatment solution of 0.5wt% of isothiazolin-3-ketone and 0.5wt% of m-nitrobenzene sodium sulfonate uses the P-B0 horizontal padding machine to pad the prepared pretreatment solution to cotton / polyamide fabrics, On pure cotton fabric and pure polyamide fabric, the pressure on both sides of the roll is 0.1kg / cm 2 , the roll speed is 12r / min, and the liquid carrying rate of the fabric is (75±1)%. The fabric after padding is dried at 100° C. to obtain the treated fabric to be printed. Inkjet printing was carried out on the treated fabric according to the second part of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com